LM386 making music with a voice-activated lights circuit

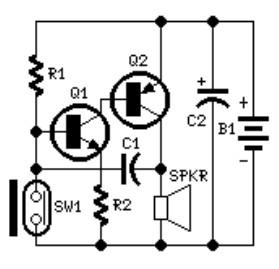

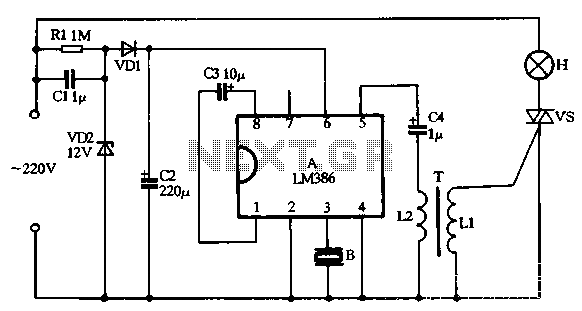

VD1, VD2, C1, and C2 comprise a simple half-wave rectifier capacitor step-down voltage regulator circuit, providing an output of approximately 12V for a linear power supply connected to the LM386. The LM386 is linked to the inverting input terminal (pin 3) and interfaces with a piezoelectric ceramic sheet B, which receives environmental acoustic signals and converts them into corresponding electrical signals. The amplified output from the internal circuit appears at pin 5 and is coupled through C4 to a bidirectional thyristor (VS). The conduction angle of the thyristor is modulated based on the strength of the received signals, allowing for the lantern string H to emit flashing light in response to the strength of the acoustic environment.

The circuit functions as a basic power supply and signal processing unit. The half-wave rectifier formed by diodes VD1 and VD2, along with capacitors C1 and C2, provides a regulated DC voltage output suitable for powering the LM386 audio amplifier. This amplifier is specifically designed to operate with low-voltage power supplies and is capable of amplifying low-level audio signals from the piezoelectric sensor.

The piezoelectric ceramic sheet acts as a transducer, converting mechanical vibrations from the environment into electrical signals. When acoustic waves strike the piezoelectric material, it generates a voltage proportional to the intensity of the sound. This voltage is fed into the LM386, where it is amplified to a usable level.

The output from the LM386 (pin 5) is coupled through capacitor C4 to the gate of the thyristor. The thyristor's conduction angle is controlled by the amplified signal, effectively modulating the power delivered to the lantern string H. As the acoustic signal strength varies, the intensity and flash rate of the lantern's light output correspondingly change, creating a visual representation of the surrounding acoustic environment.

This circuit design is particularly useful in applications where visual indicators are needed to represent sound levels, such as in sound-activated lighting systems or audio-responsive decorations. The integration of the piezoelectric sensor with the LM386 amplifier and the thyristor control allows for a compact and efficient system capable of real-time response to environmental sounds.VD1, VD2, C1 and C2 form a simple half-wave rectifier capacitor step-down voltage regulator circuit, the output of about 12V in straight right current voltage supply manifold LM386 electricity. LM386 connected to the inverting input terminal 3 feet inside the piezoelectric ceramic sheet B receiving environment acoustic signal and converts it into a corresponding electrical signal, amplifying circuit after the internal manifold by 5 feet output by C4, T bidirectional drive thyristor vs, make vs conduction angle B with signals picked up strength and change, so can make the lantern string H with flashing light and acoustic environment signal strength.

The circuit functions as a basic power supply and signal processing unit. The half-wave rectifier formed by diodes VD1 and VD2, along with capacitors C1 and C2, provides a regulated DC voltage output suitable for powering the LM386 audio amplifier. This amplifier is specifically designed to operate with low-voltage power supplies and is capable of amplifying low-level audio signals from the piezoelectric sensor.

The piezoelectric ceramic sheet acts as a transducer, converting mechanical vibrations from the environment into electrical signals. When acoustic waves strike the piezoelectric material, it generates a voltage proportional to the intensity of the sound. This voltage is fed into the LM386, where it is amplified to a usable level.

The output from the LM386 (pin 5) is coupled through capacitor C4 to the gate of the thyristor. The thyristor's conduction angle is controlled by the amplified signal, effectively modulating the power delivered to the lantern string H. As the acoustic signal strength varies, the intensity and flash rate of the lantern's light output correspondingly change, creating a visual representation of the surrounding acoustic environment.

This circuit design is particularly useful in applications where visual indicators are needed to represent sound levels, such as in sound-activated lighting systems or audio-responsive decorations. The integration of the piezoelectric sensor with the LM386 amplifier and the thyristor control allows for a compact and efficient system capable of real-time response to environmental sounds.VD1, VD2, C1 and C2 form a simple half-wave rectifier capacitor step-down voltage regulator circuit, the output of about 12V in straight right current voltage supply manifold LM386 electricity. LM386 connected to the inverting input terminal 3 feet inside the piezoelectric ceramic sheet B receiving environment acoustic signal and converts it into a corresponding electrical signal, amplifying circuit after the internal manifold by 5 feet output by C4, T bidirectional drive thyristor vs, make vs conduction angle B with signals picked up strength and change, so can make the lantern string H with flashing light and acoustic environment signal strength.