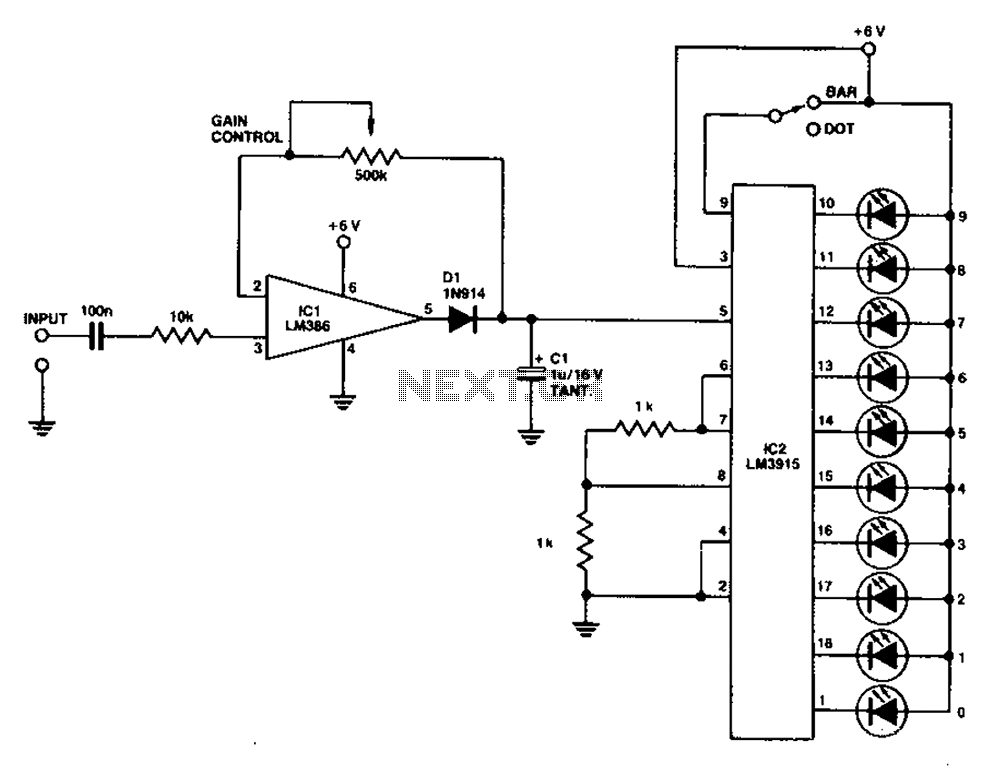

LM3915 Vibration Meter

A vibration meter circuit depicted in the schematic diagram utilizes the LM3915 as the primary active component. This vibration meter employs a piezoelectric sensor.

The vibration meter circuit is designed to measure and display vibration levels through a visual output. The core component, the LM3915, is a bar graph/LED dot display driver that can drive up to 10 LEDs in a linear or logarithmic scale. The circuit operates by converting the analog signal generated by the piezoelectric sensor into a corresponding visual representation of vibration intensity.

The piezoelectric sensor generates an electrical signal when subjected to mechanical stress or vibration. This signal is typically a small AC voltage that varies with the frequency and amplitude of the vibrations. To process this signal, the circuit includes an amplifier stage to boost the sensor output to a suitable level for the LM3915. This amplifier may consist of an operational amplifier configured in a non-inverting mode, ensuring that the output voltage is sufficient for accurate LED driving.

Following amplification, the signal may pass through a rectifier circuit to convert the AC signal from the piezoelectric sensor into a DC voltage. This rectified signal is then filtered to remove any high-frequency noise, ensuring that the LM3915 receives a clean and stable input voltage for accurate display.

The LM3915 is configured to operate in a dot mode, illuminating one LED at a time to indicate the level of vibration. The number of LEDs lit corresponds to the amplitude of the input signal, allowing users to quickly assess vibration levels visually. The circuit can be calibrated to represent specific vibration thresholds, enabling the user to set alarm levels or indicators based on the application requirements.

Power supply considerations for this circuit are crucial, as the LM3915 typically operates within a range of 3V to 25V. A regulated power supply ensures consistent performance and accurate readings. Additionally, protective components such as diodes may be included to safeguard the circuit from voltage spikes that could occur due to sudden vibrations.

Overall, this vibration meter circuit effectively combines the piezoelectric sensor's sensitivity with the visual output capabilities of the LM3915, making it a practical tool for monitoring vibration levels in various applications, including industrial machinery, automotive systems, and structural health monitoring.A vibration meter circuit shown in the following schematic diagram uses LM3915 a the main active component. This vibration meter uses a piezoelectric.. 🔗 External reference

The vibration meter circuit is designed to measure and display vibration levels through a visual output. The core component, the LM3915, is a bar graph/LED dot display driver that can drive up to 10 LEDs in a linear or logarithmic scale. The circuit operates by converting the analog signal generated by the piezoelectric sensor into a corresponding visual representation of vibration intensity.

The piezoelectric sensor generates an electrical signal when subjected to mechanical stress or vibration. This signal is typically a small AC voltage that varies with the frequency and amplitude of the vibrations. To process this signal, the circuit includes an amplifier stage to boost the sensor output to a suitable level for the LM3915. This amplifier may consist of an operational amplifier configured in a non-inverting mode, ensuring that the output voltage is sufficient for accurate LED driving.

Following amplification, the signal may pass through a rectifier circuit to convert the AC signal from the piezoelectric sensor into a DC voltage. This rectified signal is then filtered to remove any high-frequency noise, ensuring that the LM3915 receives a clean and stable input voltage for accurate display.

The LM3915 is configured to operate in a dot mode, illuminating one LED at a time to indicate the level of vibration. The number of LEDs lit corresponds to the amplitude of the input signal, allowing users to quickly assess vibration levels visually. The circuit can be calibrated to represent specific vibration thresholds, enabling the user to set alarm levels or indicators based on the application requirements.

Power supply considerations for this circuit are crucial, as the LM3915 typically operates within a range of 3V to 25V. A regulated power supply ensures consistent performance and accurate readings. Additionally, protective components such as diodes may be included to safeguard the circuit from voltage spikes that could occur due to sudden vibrations.

Overall, this vibration meter circuit effectively combines the piezoelectric sensor's sensitivity with the visual output capabilities of the LM3915, making it a practical tool for monitoring vibration levels in various applications, including industrial machinery, automotive systems, and structural health monitoring.A vibration meter circuit shown in the following schematic diagram uses LM3915 a the main active component. This vibration meter uses a piezoelectric.. 🔗 External reference