Loudspeaker Protector Monitors Current

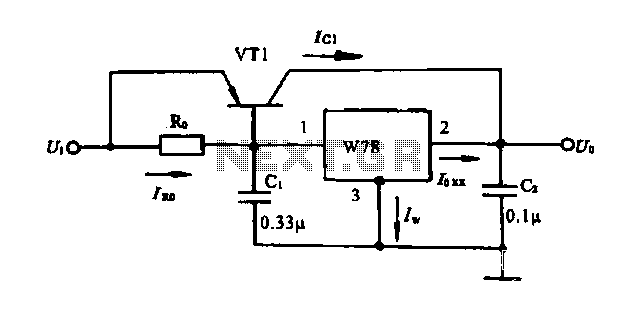

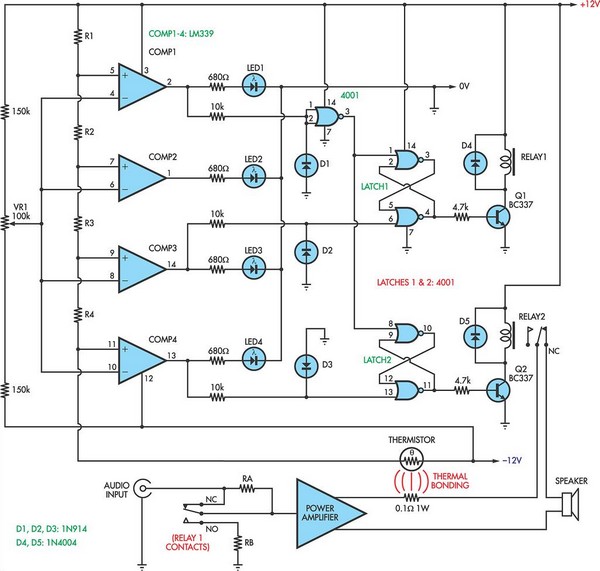

This circuit utilizes a 0.1Ω 1W resistor connected in series with the output of a power amplifier. When the amplifier delivers 100W into an 8Ω load, the resistor dissipates 1.25W. The temperature rise is detected by a thermistor thermally bonded to the resistor. The thermistor is connected in series with a resistor string, which is monitored by the non-inverting (+) inputs of four comparators in an LM339 quad comparator. The inverting inputs of all comparators are linked to an adjustable threshold voltage provided by trimpot VR1. As the thermistor heats up, its resistance increases, raising the voltage along the resistor ladder. When the voltage at the non-inverting input of each comparator exceeds the voltage at its inverting input, the output switches high and activates the corresponding LED. NOR gates are connected to the outputs of the third and fourth comparators. When the third comparator switches high, the first latch is set, turning on Q1 and relay 1, which engages an attenuation network (resistors RA & RB) to lower the power level. If the power level remains excessive, comparator 4 will activate, setting its latch and turning on Q2 and relay 2, which disconnects the loudspeaker load. The thermistor must cool down before normal operation resumes. The values of resistors R1-R4 depend on the thermistor used. For example, if a thermistor with a resistance of 1.5kΩ at 25°C is employed, R1 could be approximately 1.5kΩ, while R2, R3, and R4 would each be 100Ω, depending on the thermistor's temperature coefficient. The setup procedure includes connecting a sine wave oscillator to the input of the power amplifier and using a dummy load for the output. The desired power level should be set, and trimpot VR1 adjusted to illuminate LED1. Subsequently, increasing the power will verify that the other LEDs light up at appropriate levels.

The circuit in question is a thermal protection system designed for use in high-power audio amplifier applications. It primarily serves to prevent damage to the amplifier and connected loudspeakers by monitoring the temperature of a critical component, the series resistor, which experiences significant power dissipation during operation.

The power amplifier outputs a maximum of 100W into an 8Ω load, leading to a power dissipation of 1.25W across the 0.1Ω resistor. This resistor's temperature rise is directly proportional to the power being handled by the amplifier. The thermistor, which is thermally bonded to the resistor, plays a crucial role in this circuit by changing its resistance in response to temperature variations.

The LM339 quad comparator integrates four comparators, each monitoring the voltage across a resistor ladder connected to the thermistor. The adjustable threshold voltage, set by trimpot VR1, allows for calibration based on the specific characteristics of the thermistor used. As the thermistor heats up and its resistance increases, the voltage at the non-inverting inputs of the comparators rises. When this voltage exceeds the threshold set at the inverting inputs, the comparators output a high signal, activating the corresponding LED indicators.

The circuit incorporates a dual-layer safety mechanism through the use of NOR gates connected to the outputs of the third and fourth comparators. The first latch, controlled by the third comparator, engages relay 1 and the attenuation network, which consists of resistors RA and RB. This network reduces the power output of the amplifier to prevent overheating. If the temperature continues to rise, the fourth comparator will trigger the second latch, activating relay 2, which disconnects the loudspeaker load entirely, safeguarding both the amplifier and the speakers from damage.

The design of the resistor values (R1-R4) is critical and should be tailored to the specific thermistor being used. The example provided indicates that with a thermistor rated at 1.5kΩ at 25°C, the resistor values can be adjusted accordingly to ensure accurate temperature monitoring and response.

For setup, the circuit requires a sine wave oscillator connected to the input of the power amplifier, with a dummy load at the output to simulate real-world conditions. Calibration involves setting the desired power level and adjusting trimpot VR1 to ensure that LED1 illuminates, followed by testing the system under increased power conditions to confirm that all LEDs activate as expected, indicating proper functionality of the thermal protection mechanism.This circuit uses a 0. 1O 1W resistor connected in series with the output of a power amplifier. When the amplifier is delivering 100W into an 8O load, the resistor will be dissipating 1. 25W. The resulting temperature rise is sensed by a thermistor which is thermally bonded to the resistor. The thermistor is connected in series with a resistor strin g which is monitored by the non-inverting (+) inputs of four comparators in an LM339 quad comparator. All of the comparator inverting inputs are connected to an adjustable threshold voltage provided by trimpot VR1.

As the thermistor heats up, its resistance increases, raising the voltage along the resistor ladder. When the voltage on the non-inverting input of each comparator exceeds the voltage at its inverting input, the output switches high and illuminates the relevant LED. NOR gate latches are connected to the outputs of the third and fourth comparators. When the third comparator switches high, the first latch is set, turning on Q1 and relay 1. This switches in an attenuation network (resistors RA & RB) to reduce the power level. However, if the power level is still excessive, comparator 4 will switch, setting its latch and turning on Q2 and relay 2.

This disconnects the loudspeaker load. The thermistor then needs to cool down before normal operation will be restored. The values of R1-R4 depend on the thermistor used. For example, if a thermistor with a resistance of 1. 5kO at 25 °C is used, then R1 could be around 1. 5kO and R2, R3 and R4 would each be 100O (depending the temperature coefficient of the thermistor). The setup procedure involves connecting a sinewave oscillator to the input of the power amplifier and using a dummy load for the output. Set the power level desired and adjust trimpot VR1 to light LED1. Then increase the power to check that the other LEDs light at satisfactory levels. 🔗 External reference

The circuit in question is a thermal protection system designed for use in high-power audio amplifier applications. It primarily serves to prevent damage to the amplifier and connected loudspeakers by monitoring the temperature of a critical component, the series resistor, which experiences significant power dissipation during operation.

The power amplifier outputs a maximum of 100W into an 8Ω load, leading to a power dissipation of 1.25W across the 0.1Ω resistor. This resistor's temperature rise is directly proportional to the power being handled by the amplifier. The thermistor, which is thermally bonded to the resistor, plays a crucial role in this circuit by changing its resistance in response to temperature variations.

The LM339 quad comparator integrates four comparators, each monitoring the voltage across a resistor ladder connected to the thermistor. The adjustable threshold voltage, set by trimpot VR1, allows for calibration based on the specific characteristics of the thermistor used. As the thermistor heats up and its resistance increases, the voltage at the non-inverting inputs of the comparators rises. When this voltage exceeds the threshold set at the inverting inputs, the comparators output a high signal, activating the corresponding LED indicators.

The circuit incorporates a dual-layer safety mechanism through the use of NOR gates connected to the outputs of the third and fourth comparators. The first latch, controlled by the third comparator, engages relay 1 and the attenuation network, which consists of resistors RA and RB. This network reduces the power output of the amplifier to prevent overheating. If the temperature continues to rise, the fourth comparator will trigger the second latch, activating relay 2, which disconnects the loudspeaker load entirely, safeguarding both the amplifier and the speakers from damage.

The design of the resistor values (R1-R4) is critical and should be tailored to the specific thermistor being used. The example provided indicates that with a thermistor rated at 1.5kΩ at 25°C, the resistor values can be adjusted accordingly to ensure accurate temperature monitoring and response.

For setup, the circuit requires a sine wave oscillator connected to the input of the power amplifier, with a dummy load at the output to simulate real-world conditions. Calibration involves setting the desired power level and adjusting trimpot VR1 to ensure that LED1 illuminates, followed by testing the system under increased power conditions to confirm that all LEDs activate as expected, indicating proper functionality of the thermal protection mechanism.This circuit uses a 0. 1O 1W resistor connected in series with the output of a power amplifier. When the amplifier is delivering 100W into an 8O load, the resistor will be dissipating 1. 25W. The resulting temperature rise is sensed by a thermistor which is thermally bonded to the resistor. The thermistor is connected in series with a resistor strin g which is monitored by the non-inverting (+) inputs of four comparators in an LM339 quad comparator. All of the comparator inverting inputs are connected to an adjustable threshold voltage provided by trimpot VR1.

As the thermistor heats up, its resistance increases, raising the voltage along the resistor ladder. When the voltage on the non-inverting input of each comparator exceeds the voltage at its inverting input, the output switches high and illuminates the relevant LED. NOR gate latches are connected to the outputs of the third and fourth comparators. When the third comparator switches high, the first latch is set, turning on Q1 and relay 1. This switches in an attenuation network (resistors RA & RB) to reduce the power level. However, if the power level is still excessive, comparator 4 will switch, setting its latch and turning on Q2 and relay 2.

This disconnects the loudspeaker load. The thermistor then needs to cool down before normal operation will be restored. The values of R1-R4 depend on the thermistor used. For example, if a thermistor with a resistance of 1. 5kO at 25 °C is used, then R1 could be around 1. 5kO and R2, R3 and R4 would each be 100O (depending the temperature coefficient of the thermistor). The setup procedure involves connecting a sinewave oscillator to the input of the power amplifier and using a dummy load for the output. Set the power level desired and adjust trimpot VR1 to light LED1. Then increase the power to check that the other LEDs light at satisfactory levels. 🔗 External reference