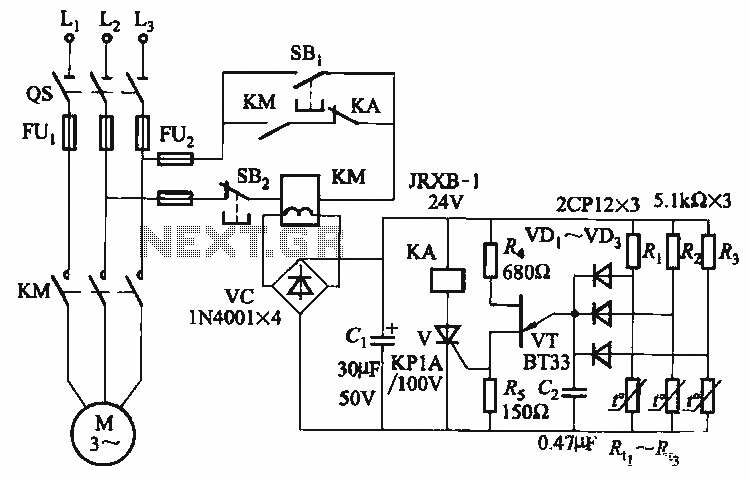

Motor speed control

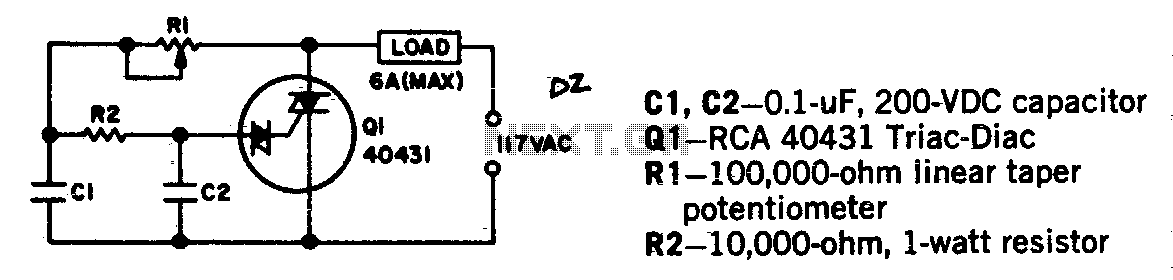

Universal motors and shaded-pole induction motors can be effectively controlled using a full-wave Triac speed controller. Component Q1 integrates both the Triac and diac trigger diodes within a single package. The motor employed for the load should not exceed a maximum current rating of 6 amperes. Additionally, Triac Q1 must be equipped with a heat sink. With the specified component values, the Triac is capable of regulating motor speed from a complete stop to full operation.

The circuit design utilizes a Triac-based speed controller, which is particularly suitable for universal motors and shaded-pole induction motors. The Triac serves as a semiconductor device that can control power flow to the motor, allowing for smooth variation in speed. The integration of the diac trigger diode within the same package as the Triac simplifies the design and reduces the number of discrete components required.

The operational principle involves phase control, where the Triac is triggered at a specific point in the AC waveform. By adjusting the firing angle of the Triac, the average voltage and current supplied to the motor can be modulated, thus controlling the speed. The component values, such as resistors and capacitors in the timing circuit, are critical for determining the firing angle and, consequently, the speed range of the motor.

The maximum current rating of 6 amperes for the motor ensures that it operates within safe limits, preventing overheating and potential damage to the circuit. The requirement for a heat sink on the Triac is essential for thermal management, as the device can generate significant heat during operation, especially under high load conditions. Proper heat dissipation is necessary to maintain reliability and longevity of the Triac.

Overall, this Triac speed controller circuit offers a versatile solution for controlling the speed of various motor types, providing a practical approach to applications requiring precise motor speed regulation.Universal motors and shade d-pole induction motors can be easily controlled with a full-wave Triac speed controller. Q1 combines both the triac and diac trigger diodes in the same case. The motor used for the load must be limited to 6 amperes maximum. Triac Ql must be provided with a heat sink With the component values shown, the Triac controls motor speed"from full off to full on.

The circuit design utilizes a Triac-based speed controller, which is particularly suitable for universal motors and shaded-pole induction motors. The Triac serves as a semiconductor device that can control power flow to the motor, allowing for smooth variation in speed. The integration of the diac trigger diode within the same package as the Triac simplifies the design and reduces the number of discrete components required.

The operational principle involves phase control, where the Triac is triggered at a specific point in the AC waveform. By adjusting the firing angle of the Triac, the average voltage and current supplied to the motor can be modulated, thus controlling the speed. The component values, such as resistors and capacitors in the timing circuit, are critical for determining the firing angle and, consequently, the speed range of the motor.

The maximum current rating of 6 amperes for the motor ensures that it operates within safe limits, preventing overheating and potential damage to the circuit. The requirement for a heat sink on the Triac is essential for thermal management, as the device can generate significant heat during operation, especially under high load conditions. Proper heat dissipation is necessary to maintain reliability and longevity of the Triac.

Overall, this Triac speed controller circuit offers a versatile solution for controlling the speed of various motor types, providing a practical approach to applications requiring precise motor speed regulation.Universal motors and shade d-pole induction motors can be easily controlled with a full-wave Triac speed controller. Q1 combines both the triac and diac trigger diodes in the same case. The motor used for the load must be limited to 6 amperes maximum. Triac Ql must be provided with a heat sink With the component values shown, the Triac controls motor speed"from full off to full on.