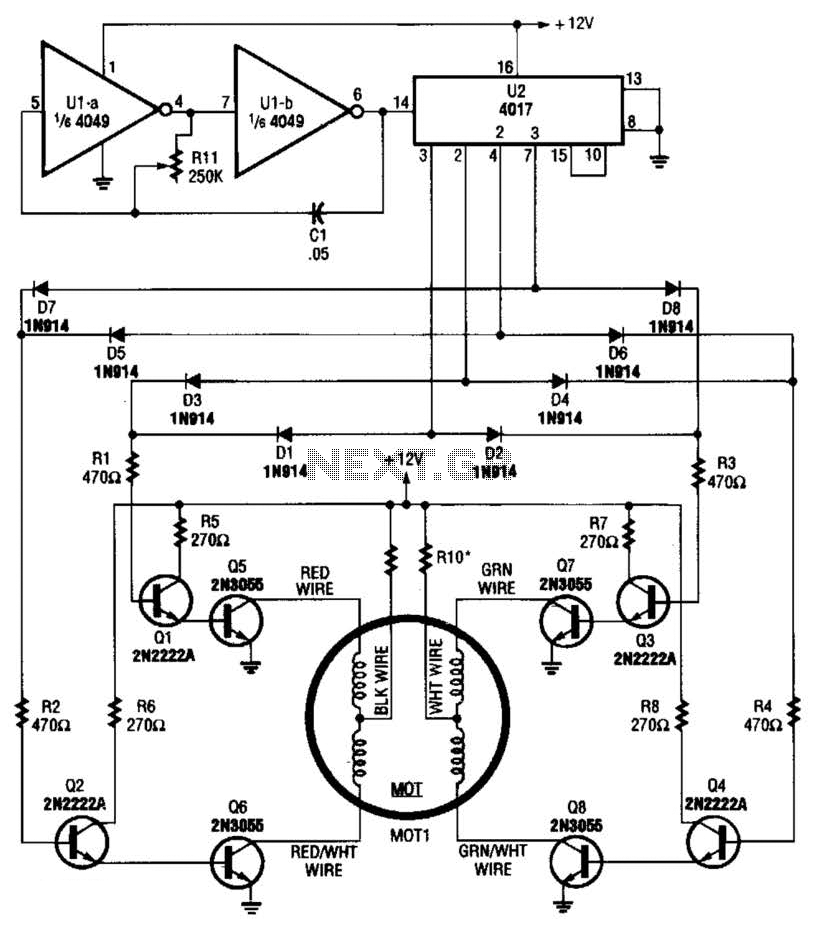

Multi-unit slip motor speed control system synchronous operation circuit

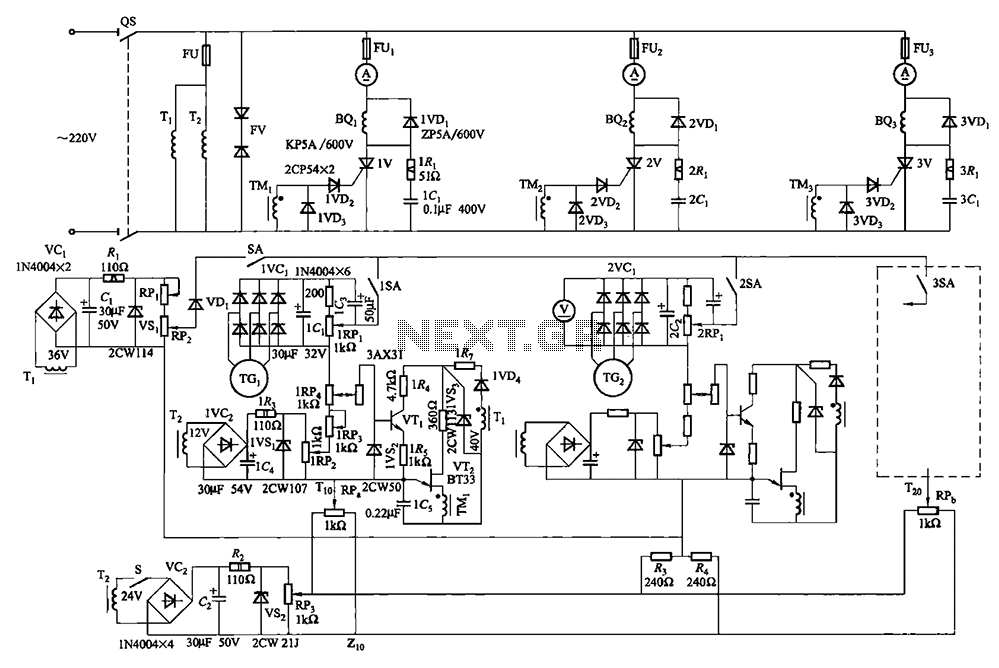

Collaboration with the dancers balanced bridge long on the porcelain unit. A sync adjustment rheostat speed control system is shown in Figure 3. The principle of speed control for electro-magnetic and photoelectric dancers is similar. The main motor (BQ2) allows for slip (i.e., a reference speed) of the field winding. BQi and BQ3 are oriented to manage the slip of the front and rear of the motor's field winding. The RPz potentiometer can be adjusted to change the speed of the entire system (i.e., the slip of three motors). TGi to TG3 are three tachometer generators connected to the respective electromagnetic slip clutch shaft of the motor. The adjustment potentiometers (1RP1, 2RP1, 3RP1) can modify the negative feedback voltage corresponding to each slip motor speed, which may lead to speed changes. The sensitivity potentiometers (1RP2, 2RP2, 3RP2) can be adjusted to change the corresponding slip speed of the motors. The dish rheostats (RP., RPb) are used to coordinate the three slip speeds of the motors, ensuring they operate synchronously.

The described system incorporates a balanced bridge configuration that collaborates with dancers to achieve precise control of motor speeds within a porcelain unit. The sync adjustment rheostat plays a critical role in fine-tuning the speed control system, which is visually represented in the referenced figure. The electro-magnetic and photoelectric dancers operate under a similar principle, utilizing the main motor (BQ2) to establish a slip reference speed through its field winding.

The orientation of BQi and BQ3 is strategically designed to manage the slip of the motor's field winding effectively. The RPz potentiometer is essential for adjusting the overall speed of the system, allowing for flexibility in the operation of three motors simultaneously. Each motor's slip can be finely tuned, thanks to the integration of tachometer generators (TGi to TG3), which are connected to the electromagnetic slip clutch shafts of the respective motors.

The adjustment potentiometers (1RP1, 2RP1, 3RP1) are vital for modifying the negative feedback voltage associated with each motor's slip speed, providing a mechanism for dynamic speed adjustments. Furthermore, the sensitivity potentiometers (1RP2, 2RP2, 3RP2) allow for precise alterations to the slip speeds, enhancing the responsiveness of the system to changes in operational conditions.

The dish rheostats (RP., RPb) serve a crucial function in synchronizing the slip speeds of the three motors, ensuring that they operate in unison. This synchronization is vital for applications where coordinated movement is required, enhancing the overall performance and reliability of the system. The combination of these components creates a sophisticated speed control system that can adapt to varying operational demands while maintaining precise control over motor performance. Collaboration with the dancers balanced bridge long on the porcelain unit Sync adjustment rheostat speed control system shown in Figure 3 to 183 in FIG. Others, such as electro magnetic, photoelectric dancers speed control principle is similar. FIG, BQ2 main motor so that the slip (i.e., as a reference speed) of the field winding, BQi and BQ3 are oriented so that the slip of the front and rear of the motor slip motor field winding. RPz based order potentiometer, which can be adjusted to change the entire system (ie, three motor slip) speed.

TGi ~ TG3 for the three tachometer generator, they are connected with the respective electromagnetic slip clutch shaft of the motor. Adjust potentiometer 1RP1 (2RPi, 3RPl) can change the size of each slip motor speed negative feedback voltage (may cause speed changes).

lRP2 (2RP2,3RP2) the sensitivity potentiometer, which can be adjusted to change a corresponding slip speed of the motor. Dish rheostat RP., RPb to coordinate three slip speed of the motor, so that they run synchronously.

The described system incorporates a balanced bridge configuration that collaborates with dancers to achieve precise control of motor speeds within a porcelain unit. The sync adjustment rheostat plays a critical role in fine-tuning the speed control system, which is visually represented in the referenced figure. The electro-magnetic and photoelectric dancers operate under a similar principle, utilizing the main motor (BQ2) to establish a slip reference speed through its field winding.

The orientation of BQi and BQ3 is strategically designed to manage the slip of the motor's field winding effectively. The RPz potentiometer is essential for adjusting the overall speed of the system, allowing for flexibility in the operation of three motors simultaneously. Each motor's slip can be finely tuned, thanks to the integration of tachometer generators (TGi to TG3), which are connected to the electromagnetic slip clutch shafts of the respective motors.

The adjustment potentiometers (1RP1, 2RP1, 3RP1) are vital for modifying the negative feedback voltage associated with each motor's slip speed, providing a mechanism for dynamic speed adjustments. Furthermore, the sensitivity potentiometers (1RP2, 2RP2, 3RP2) allow for precise alterations to the slip speeds, enhancing the responsiveness of the system to changes in operational conditions.

The dish rheostats (RP., RPb) serve a crucial function in synchronizing the slip speeds of the three motors, ensuring that they operate in unison. This synchronization is vital for applications where coordinated movement is required, enhancing the overall performance and reliability of the system. The combination of these components creates a sophisticated speed control system that can adapt to varying operational demands while maintaining precise control over motor performance. Collaboration with the dancers balanced bridge long on the porcelain unit Sync adjustment rheostat speed control system shown in Figure 3 to 183 in FIG. Others, such as electro magnetic, photoelectric dancers speed control principle is similar. FIG, BQ2 main motor so that the slip (i.e., as a reference speed) of the field winding, BQi and BQ3 are oriented so that the slip of the front and rear of the motor slip motor field winding. RPz based order potentiometer, which can be adjusted to change the entire system (ie, three motor slip) speed.

TGi ~ TG3 for the three tachometer generator, they are connected with the respective electromagnetic slip clutch shaft of the motor. Adjust potentiometer 1RP1 (2RPi, 3RPl) can change the size of each slip motor speed negative feedback voltage (may cause speed changes).

lRP2 (2RP2,3RP2) the sensitivity potentiometer, which can be adjusted to change a corresponding slip speed of the motor. Dish rheostat RP., RPb to coordinate three slip speed of the motor, so that they run synchronously.