Nickel Metal Hydride ( NiMH ) Charger

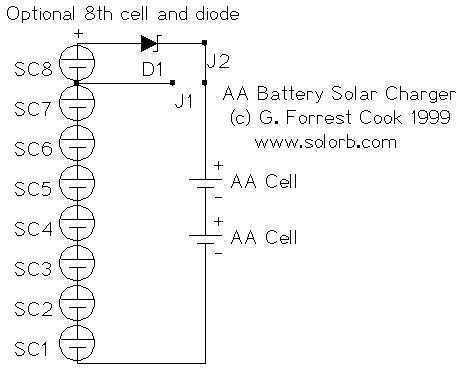

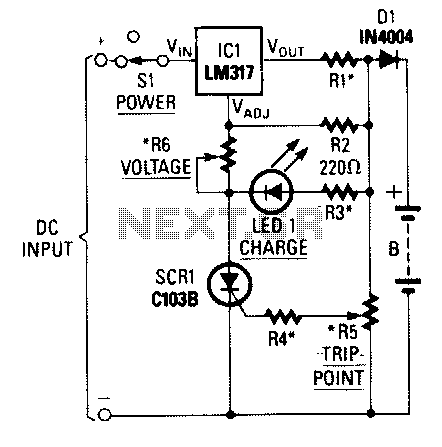

This circuit will charge a 12v battery (10 NiMH cells) @ approx 220mA. It is a very simple circuit but requires correct setting up. The circuit is designed around a 12vDC, 500mA plug pack. This type of plug pack delivers about 17.5v to 18.5v DC on no-load and about 13v when the current is 500mA. Our circuit delivers 220mA to a set of AA cells and the output of the plug pack is approx 16v (when 220mA flows) and the voltage across a set of 10 NiMH AA cells is approx 13.5v during the charging process. This gives approx 4.5v for the "head voltage," and this creates the situation where the plug pack will deliver a current to the battery. More: Do not use a 300mA plug pack. It will get too hot in this application. Some 12v DC 500mA plug packs are quite small, others are much larger. What is the difference? Plug packs (actually the transformer part of the plug pack) have a hidden rating called REGULATION and for this application you must use the biggest and heaviest plug pack you can buy. REGULATION is the comparison of the voltage under load with the voltage on no-load. When the voltage under load is only slightly less than the no-load voltage, the transformer is said to have Good Regulation. If we take a small 12v DC 500mA plug pack, the no-load voltage may be 17.5v, but the fully loaded voltage may drop to 11.9v. A larger 12v 500mA plug pack will have a no-load voltage of 17.5v, but the fully loaded voltage will drop to 13.2v. When a smaller current is drawn from the plug pack, the output voltage is slightly higher. That's why we can use a 12v DC plug pack for this application. We need about 13.6v to charge 10 NiMH cells and a large 500mA plug pack will deliver more than this voltage when the current is 220mA. The small plug pack will not work at all. But we can't connect a plug pack to the 12v battery without making an important test. You must place a multi-meter (set to 500mA or higher) in series with one lead when the plug pack is connected to the 12v battery. The diagram below shows you how to do this. It will take up to 24 hours to charge a set of exhausted 2400mA-hr AA cells and you will not have the worry of overcharging them. If you have cells with a lower capacity, you will have to reduce the current accordingly. For 1800mA-hr cells, deliver about 150mA. For larger cells, such as C and D, you can charge them at 220mA for more than 24 hours. You must remember, when a plug pack is used in most situations such as a radio etc, the current requirement varies enormously with the volume and type of music etc. That's why a plug pack will not normally get very hot. If the current flow is more than 260mA, you will need to reduce it by adding a resistor in series with one lead. In most cases, the lowest value resistor in your "parts bin" will be 10R (brown, black, black, gold).

The circuit described is designed to charge a 12V battery composed of 10 NiMH cells, with a targeted charging current of approximately 220mA. This circuit operates with a 12V DC plug pack rated at 500mA, which is crucial for ensuring adequate charging without overheating. The plug pack's performance varies under load; it delivers approximately 17.5V to 18.5V when not connected to a load and drops to around 13V when supplying 500mA. When charging, the output voltage of the plug pack is expected to be around 16V, while the voltage across the battery cells will stabilize at approximately 13.5V.

The difference in plug pack sizes relates to their regulation characteristics. A well-regulated plug pack will maintain a voltage close to its no-load voltage even under load, which is essential for effective charging. A smaller plug pack may drop significantly in voltage when loaded, rendering it ineffective for this application. A larger plug pack will maintain a higher voltage under load, which is necessary to provide the required charging voltage of about 13.6V for the NiMH cells.

Before connecting the plug pack to the battery, it is imperative to perform a test using a multi-meter set to a current rating of 500mA or higher, placed in series with one lead. This ensures that the circuit operates within safe parameters and prevents overcharging. The charging process may take up to 24 hours for fully depleted 2400mA-hr AA cells. For cells with lower capacities, the charging current should be adjusted accordingly.

To prevent excessive current draw, especially if the current exceeds 260mA, a resistor may be added in series with the charging circuit. The recommended resistor value is typically 10 ohms, which is commonly available. This circuit design allows for a straightforward and effective method of charging NiMH batteries while ensuring safety and efficiency.This circuit will charge a 12v battery (10 NiMH cells) @ approx 220mA. It is a very simple circuit but requires correct setting up. The circuit is designed around a 12vDC, 500mA plug pack. This type of plug pack delivers about 17.5v to 18.5v DC on no-load and about 13v when the current is 500mA. Our circuit delivers 220mA to a set of AA cells and the output of the plug pack is approx 16v (when 220mA flows) and the voltage across a set of 10 NiMH AA cells is approx 13.5v during the charging process.

This gives approx 4.5v for the "head voltage," and this creates the situation where the plug pack will deliver a current to the battery. Do not use a 300mA plug pack. It will get too hot in this application. Some 12v DC 500mA plug packs are quite small, others are much larger. What is the difference? Plug packs (actually the transformer part of the plug pack) have a hidden rating called REGULATION and for this application you must use the biggest and heaviest plug pack you can buy. REGULATION is the comparison of the voltage under load with the voltage on no-load. When the voltage under load is only slightly les than the no-load voltage, the transformer is said to have Good Regulation.

If we take a small 12v DC 500mA plug pack, the no-load voltage may be 17.5v, but the fully loaded voltage may drop to 11.9v. A larger 12v 500mA plug pack will have a no-load voltage of 17.5v, but the fully loaded voltage will drop to 13.2v.

When a smaller current is drawn from the plug pack, the output voltage is slightly higher. That's why we can use a 12v DC plug pack for this application. We need about 13.6v to charge 10 NiMH cells and a large 500mA plug pack will deliver more than this voltage when the current is 220mA. The small plug pack will not work at all. But we can't connect a plug pack to the 12v battery without making an important test. You must place a multi-meter (set to 500mA or higher) in series with one lead when the plug pack is connected to the 12v battery.

The diagram below shows you how to do this. It will take up to 24 hours to charge a set of exhausted 2400mA-hr AA cells and you will not have the worry of overcharging them. If you have cells with a lower capacity, you will have to reduce the current accordingly. For 1800mA-hr cells, deliver about 150mA. For larger cells, such as C and D, you can charge them at 220mA for more than 24 hours. You must remember, when a plug pack is used in most situations such as a radio etc, the current requirement varies enormously with the volume and type of music etc.

That's why a plug pack will not normally get very hot. If the current flow is more than 260mA, you will need to reduce it by adding a resistor in series with one lead. In most cases, the lowest value resistor in your "parts bin" will be 10R (brown, black, black, gold).

🔗 External reference

The circuit described is designed to charge a 12V battery composed of 10 NiMH cells, with a targeted charging current of approximately 220mA. This circuit operates with a 12V DC plug pack rated at 500mA, which is crucial for ensuring adequate charging without overheating. The plug pack's performance varies under load; it delivers approximately 17.5V to 18.5V when not connected to a load and drops to around 13V when supplying 500mA. When charging, the output voltage of the plug pack is expected to be around 16V, while the voltage across the battery cells will stabilize at approximately 13.5V.

The difference in plug pack sizes relates to their regulation characteristics. A well-regulated plug pack will maintain a voltage close to its no-load voltage even under load, which is essential for effective charging. A smaller plug pack may drop significantly in voltage when loaded, rendering it ineffective for this application. A larger plug pack will maintain a higher voltage under load, which is necessary to provide the required charging voltage of about 13.6V for the NiMH cells.

Before connecting the plug pack to the battery, it is imperative to perform a test using a multi-meter set to a current rating of 500mA or higher, placed in series with one lead. This ensures that the circuit operates within safe parameters and prevents overcharging. The charging process may take up to 24 hours for fully depleted 2400mA-hr AA cells. For cells with lower capacities, the charging current should be adjusted accordingly.

To prevent excessive current draw, especially if the current exceeds 260mA, a resistor may be added in series with the charging circuit. The recommended resistor value is typically 10 ohms, which is commonly available. This circuit design allows for a straightforward and effective method of charging NiMH batteries while ensuring safety and efficiency.This circuit will charge a 12v battery (10 NiMH cells) @ approx 220mA. It is a very simple circuit but requires correct setting up. The circuit is designed around a 12vDC, 500mA plug pack. This type of plug pack delivers about 17.5v to 18.5v DC on no-load and about 13v when the current is 500mA. Our circuit delivers 220mA to a set of AA cells and the output of the plug pack is approx 16v (when 220mA flows) and the voltage across a set of 10 NiMH AA cells is approx 13.5v during the charging process.

This gives approx 4.5v for the "head voltage," and this creates the situation where the plug pack will deliver a current to the battery. Do not use a 300mA plug pack. It will get too hot in this application. Some 12v DC 500mA plug packs are quite small, others are much larger. What is the difference? Plug packs (actually the transformer part of the plug pack) have a hidden rating called REGULATION and for this application you must use the biggest and heaviest plug pack you can buy. REGULATION is the comparison of the voltage under load with the voltage on no-load. When the voltage under load is only slightly les than the no-load voltage, the transformer is said to have Good Regulation.

If we take a small 12v DC 500mA plug pack, the no-load voltage may be 17.5v, but the fully loaded voltage may drop to 11.9v. A larger 12v 500mA plug pack will have a no-load voltage of 17.5v, but the fully loaded voltage will drop to 13.2v.

When a smaller current is drawn from the plug pack, the output voltage is slightly higher. That's why we can use a 12v DC plug pack for this application. We need about 13.6v to charge 10 NiMH cells and a large 500mA plug pack will deliver more than this voltage when the current is 220mA. The small plug pack will not work at all. But we can't connect a plug pack to the 12v battery without making an important test. You must place a multi-meter (set to 500mA or higher) in series with one lead when the plug pack is connected to the 12v battery.

The diagram below shows you how to do this. It will take up to 24 hours to charge a set of exhausted 2400mA-hr AA cells and you will not have the worry of overcharging them. If you have cells with a lower capacity, you will have to reduce the current accordingly. For 1800mA-hr cells, deliver about 150mA. For larger cells, such as C and D, you can charge them at 220mA for more than 24 hours. You must remember, when a plug pack is used in most situations such as a radio etc, the current requirement varies enormously with the volume and type of music etc.

That's why a plug pack will not normally get very hot. If the current flow is more than 260mA, you will need to reduce it by adding a resistor in series with one lead. In most cases, the lowest value resistor in your "parts bin" will be 10R (brown, black, black, gold).

🔗 External reference