Parallel Port Stepper Motor Driver With Discrete Components

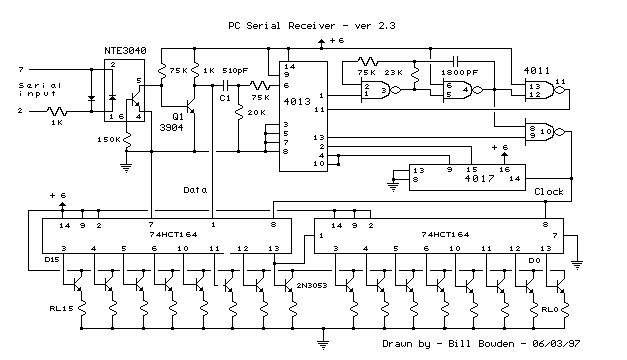

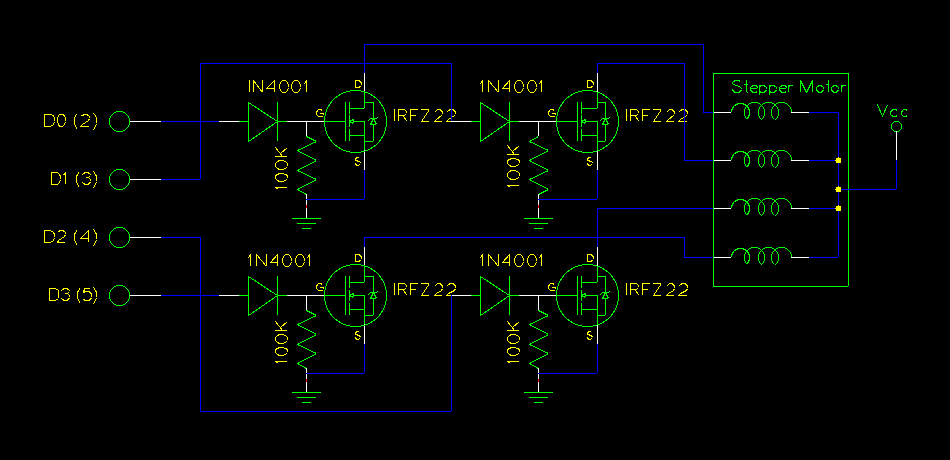

The use of a PC's parallel port provides a convenient method for controlling a stepper motor. For unipolar stepper motors, it is possible to control up to two motors using the 8-bit data line. Typically, a Darlington driver, such as the ULN2003, is employed to connect a unipolar stepper motor to the parallel port, and numerous examples are available demonstrating this setup. This post details the construction of a simple stepper motor driver utilizing discrete MOSFETs. The circuit diagram illustrates the use of four power MOSFETs as switches for each coil of the stepper motor (the example motor is a MITSUMI M35SP-9, though any unipolar stepper motor should function with this circuit). Each MOSFET is connected to a pull-down resistor at its gate, which is crucial to prevent interference from the port that may disrupt the reliable switching of the MOSFETs. The accompanying C code sets the data port (pins 2, 3, 4, and 5) to high in a specific sequence to rotate the stepper motor clockwise. To achieve counter-clockwise rotation, the output sequence should be modified to 8, 4, 2, 1.

The described circuit employs a parallel port to interface with a unipolar stepper motor through discrete MOSFETs, providing an effective means of control. The use of the ULN2003 Darlington driver is a common practice, but the implementation of MOSFETs can offer advantages in terms of efficiency and heat management. The MITSUMI M35SP-9 serves as a suitable example for this application, as it demonstrates the capabilities of the circuit with its standard unipolar configuration.

In the schematic, the four power MOSFETs are arranged to control the four coils of the stepper motor. Each MOSFET's gate is connected to a data pin on the parallel port, allowing for direct control of the motor's phases. The pull-down resistors are essential for ensuring that the gates of the MOSFETs remain in a known state when not actively driven by the parallel port, thereby preventing false triggering due to noise or interference.

The C code provided is integral to the operation of the stepper motor driver. By setting the data port pins to high in a specific order, the motor is commanded to step in a clockwise direction. The ability to reverse the motor's direction by simply altering the output sequence exemplifies the flexibility of this design. This approach allows for straightforward integration into various applications where precise motor control is required, such as robotics, CNC machines, or automated systems.

Overall, this circuit offers a practical and efficient solution for controlling unipolar stepper motors using a PC's parallel port, with the potential for further modifications and enhancements to suit specific project requirements.Using PC`s parallel port is a convenient way to control a stepper motor. For unipolar stepper motors, up to two motors can be controlled with the 8bit data line. The standard way of connecting a unipolar stepper motor to the parallel port is to use a Darlington driver such as ULN2003 and there are already many examples out there on how to do this. In this post, I will show you how to build a simple stepper motor driver using discrete MOSFET s. In the circuit diagram below, you will find that the four power MOSFETs are used as switches for each coil in the stepper motor (the stepper motor I used in this example is a MITSUMI M35SP-9. In theory, any uni-polar stepper motors should work with this circuit). A pull-down resistor is attached to the gate of each MOSFET. This is important as otherwise the interference from the port would prevent the MOSFET from switching reliably.

The following C code sets the data port (pin 2, 3, 4, 5) to high in order so that the stepper motor would rotate clockwise. If you want the motor to rotate counter-clockwise, simply change the output order to 8, 4, 2, 1. 🔗 External reference

The described circuit employs a parallel port to interface with a unipolar stepper motor through discrete MOSFETs, providing an effective means of control. The use of the ULN2003 Darlington driver is a common practice, but the implementation of MOSFETs can offer advantages in terms of efficiency and heat management. The MITSUMI M35SP-9 serves as a suitable example for this application, as it demonstrates the capabilities of the circuit with its standard unipolar configuration.

In the schematic, the four power MOSFETs are arranged to control the four coils of the stepper motor. Each MOSFET's gate is connected to a data pin on the parallel port, allowing for direct control of the motor's phases. The pull-down resistors are essential for ensuring that the gates of the MOSFETs remain in a known state when not actively driven by the parallel port, thereby preventing false triggering due to noise or interference.

The C code provided is integral to the operation of the stepper motor driver. By setting the data port pins to high in a specific order, the motor is commanded to step in a clockwise direction. The ability to reverse the motor's direction by simply altering the output sequence exemplifies the flexibility of this design. This approach allows for straightforward integration into various applications where precise motor control is required, such as robotics, CNC machines, or automated systems.

Overall, this circuit offers a practical and efficient solution for controlling unipolar stepper motors using a PC's parallel port, with the potential for further modifications and enhancements to suit specific project requirements.Using PC`s parallel port is a convenient way to control a stepper motor. For unipolar stepper motors, up to two motors can be controlled with the 8bit data line. The standard way of connecting a unipolar stepper motor to the parallel port is to use a Darlington driver such as ULN2003 and there are already many examples out there on how to do this. In this post, I will show you how to build a simple stepper motor driver using discrete MOSFET s. In the circuit diagram below, you will find that the four power MOSFETs are used as switches for each coil in the stepper motor (the stepper motor I used in this example is a MITSUMI M35SP-9. In theory, any uni-polar stepper motors should work with this circuit). A pull-down resistor is attached to the gate of each MOSFET. This is important as otherwise the interference from the port would prevent the MOSFET from switching reliably.

The following C code sets the data port (pin 2, 3, 4, 5) to high in order so that the stepper motor would rotate clockwise. If you want the motor to rotate counter-clockwise, simply change the output order to 8, 4, 2, 1. 🔗 External reference