Charger circuit V

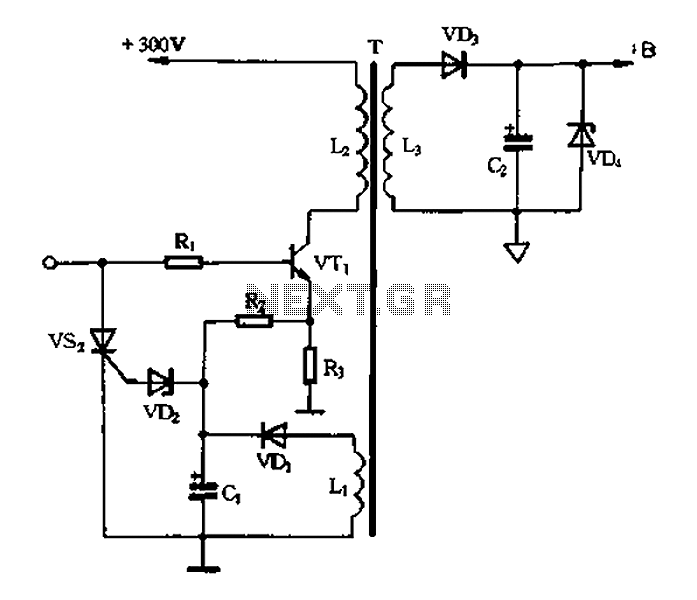

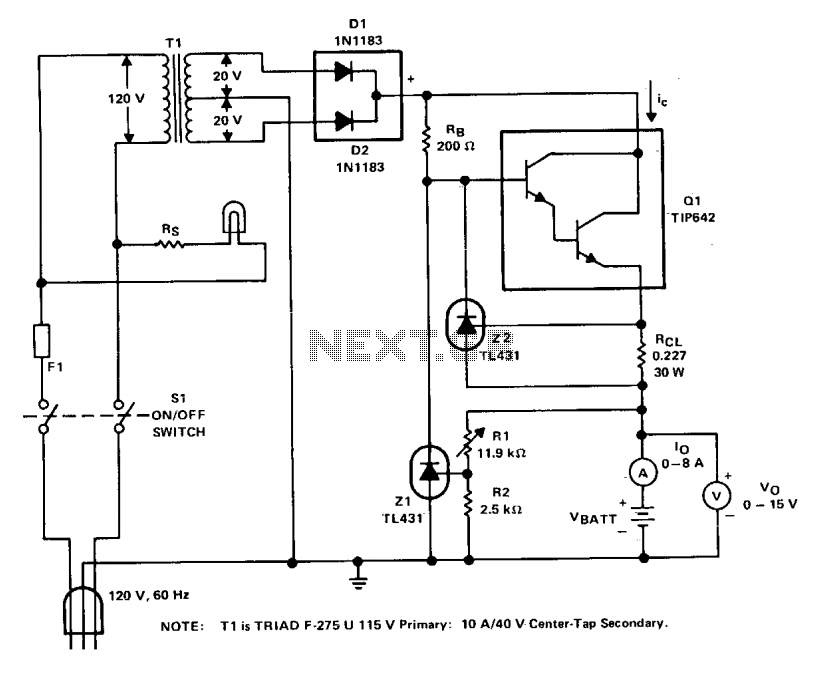

The charger operates with a charging voltage of 2.4 V per cell, aligning with the recommendations of most manufacturers. The circuit delivers a charging voltage of 14.4 V (6 cells at 2.4 V per cell) in a pulsed manner at a frequency of 120 Hz. This design incorporates current limiting features to safeguard the internal components of the charger while also restricting the charging rate to protect severely discharged lead-acid batteries. The typical maximum charging current is approximately one-fourth of the battery's ampere-hour rating. For instance, for a standard 44 ampere-hour battery, the maximum charging current is 11 A. If the load's impedance necessitates a charging current exceeding this 11 A limit, the circuit will enter a current limiting mode. The amplitude of the charging pulses is regulated to ensure that the peak charging current does not exceed 11 A, with an average current of 8 A.

The charger circuit is designed to efficiently manage the charging process of lead-acid batteries while ensuring the safety and longevity of both the charger and the battery. The charging voltage of 14.4 V is specifically chosen to optimize the charging process for six series-connected cells, each rated at 2.4 V. By operating at a frequency of 120 Hz, the circuit effectively delivers energy in controlled pulses, which helps to minimize heat generation and prolongs the life of the battery.

The current limiting feature is a critical aspect of the design, as it prevents excessive current from flowing into the battery, which can lead to overheating and potential damage. This is particularly important for lead-acid batteries that may be in a deeply discharged state, where a high initial charging current could be detrimental. The specification of charging at one-fourth the ampere-hour rating ensures that the charging process is gentle enough to safely restore the battery's charge without causing harm.

In practical terms, for a battery with a capacity of 44 ampere-hours, the charger is configured to allow a maximum charging current of 11 A. This limit is crucial when the load impedance requires more current; the circuit's ability to enter a current limiting mode ensures that the charger can adapt to varying conditions without risking damage to its components or the battery itself. The regulation of the charging pulse amplitude to maintain an average current of 8 A further enhances the safety and efficiency of the charging process, ensuring that the battery is charged effectively while minimizing the risk of overcurrent conditions.

Overall, this charger design exemplifies a well-thought-out approach to battery management, balancing efficiency, safety, and adherence to manufacturer guidelines.The charger is based on a charging voltage of 2.4 V per cell, in accordance with most manufacturers' recommendations. The circuit pulses the battery under charge with 14.4 V (6 cells ? 2.4 V per cell) at a rate of 120 Hz. The design provides current limiting to protect the charger's internal components while limiting the charging rate to prevent damaging severely discharged lead-acid batteries.

The maximum recommended charging current is normally about one-fourth the ampere-hour rating of the battery. For example, the maximum charging current for an average 44 ampere-hour battery is 11 A. If the impedance of the load requires a charging current greater than the 11 A current limit, the circuit will go into current limiting. The amplitude of the charging pulses is controlled to maintain a maximum peak charging current of 11 A (8 A average).

🔗 External reference

The charger circuit is designed to efficiently manage the charging process of lead-acid batteries while ensuring the safety and longevity of both the charger and the battery. The charging voltage of 14.4 V is specifically chosen to optimize the charging process for six series-connected cells, each rated at 2.4 V. By operating at a frequency of 120 Hz, the circuit effectively delivers energy in controlled pulses, which helps to minimize heat generation and prolongs the life of the battery.

The current limiting feature is a critical aspect of the design, as it prevents excessive current from flowing into the battery, which can lead to overheating and potential damage. This is particularly important for lead-acid batteries that may be in a deeply discharged state, where a high initial charging current could be detrimental. The specification of charging at one-fourth the ampere-hour rating ensures that the charging process is gentle enough to safely restore the battery's charge without causing harm.

In practical terms, for a battery with a capacity of 44 ampere-hours, the charger is configured to allow a maximum charging current of 11 A. This limit is crucial when the load impedance requires more current; the circuit's ability to enter a current limiting mode ensures that the charger can adapt to varying conditions without risking damage to its components or the battery itself. The regulation of the charging pulse amplitude to maintain an average current of 8 A further enhances the safety and efficiency of the charging process, ensuring that the battery is charged effectively while minimizing the risk of overcurrent conditions.

Overall, this charger design exemplifies a well-thought-out approach to battery management, balancing efficiency, safety, and adherence to manufacturer guidelines.The charger is based on a charging voltage of 2.4 V per cell, in accordance with most manufacturers' recommendations. The circuit pulses the battery under charge with 14.4 V (6 cells ? 2.4 V per cell) at a rate of 120 Hz. The design provides current limiting to protect the charger's internal components while limiting the charging rate to prevent damaging severely discharged lead-acid batteries.

The maximum recommended charging current is normally about one-fourth the ampere-hour rating of the battery. For example, the maximum charging current for an average 44 ampere-hour battery is 11 A. If the impedance of the load requires a charging current greater than the 11 A current limit, the circuit will go into current limiting. The amplitude of the charging pulses is controlled to maintain a maximum peak charging current of 11 A (8 A average).

🔗 External reference