Programmable time-lapse camera controller

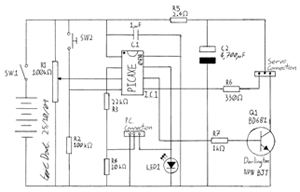

This project involves creating a programmable camera controller using basic hand tools and a digital camera. By utilizing components that are commonly found at home, the overall costs can be minimized. A servomotor can be repurposed from a radio-controlled model, and aluminum for the adapter plate can be sourced from a manufacturer's scrap bin, with prior permission required. All recommended electronic components should have a voltage rating of 6 volts or higher and can be purchased from local retailers. The project includes designing an electronic circuit, constructing an adapter plate for the servo and digital camera integration, and writing the necessary software code. An engaging aspect of this project is the ability to showcase videos created from the still photographs captured by the system. A simple initial subject can be selected, such as setting up the camera in a family room during a birthday celebration. The camera can be discreetly positioned and forgotten until the video is later reviewed, often resulting in enjoyable moments. Outdoor operation requires additional equipment protection; umbrellas can provide temporary shelter, or a waterproof container with a clear front can be utilized. Some food containers may be adapted, but it is crucial to keep the interior dry to prevent condensation from forming on sensitive electronic parts. To mitigate condensation within an enclosure, excess space can be filled with dry rags or bubble wrap while ensuring that the lens and servo remain functional. The camera should be configured to the lowest resolution with the flash disabled. Proper alignment of the camera is essential for achieving a professional appearance in the final video. When developing the software code, a flow diagram can assist in visualizing the desired outcomes. Various software solutions may exist, and experimentation with coding and components is typically conducted on a temporary breadboard before finalizing the design of the program and electronic circuit. Soldering sockets and hardware is typically one of the last steps in prototype development. The PICAXE Programmer can be launched to create a test program to verify the functionality of the LED and servo on the camera controller, or users can refer to the provided `timeLapseTest.bas` program. Notes to users are indicated with an apostrophe, which is ignored by the program compiler and not included in the code sent to the PICAXE IC. The underside of the printed circuit board (PCB) shows tracks cut with a 3 mm drill. For convenience in the prototype, a small component and jumper have been soldered onto the underside of the board. In the final version, these components should be connected on the top side of the board. All components populate the board, which is secured to a battery box cover using Blu-tack to hold it in place. The Blu-tack not only secures the circuit board but also provides clearance for components on the underside. The battery box contains four 2.4 Ah AA 1.2 Volt rechargeable NiMH cells. It is important to verify that all components from the list are present or suitable substitutes are available. A multimeter should be used to confirm that all components function correctly and that their values are accurate. On the underside of the printed circuit board, tracks should be cut to isolate the legs of the 8-pin IC socket. Subsequently, components such as resistors, jumpers, sockets, and headers should be soldered into place, ensuring proper polarity is maintained.

This programmable camera controller project offers a practical and engaging way to explore electronics and coding. The integration of a servomotor with a digital camera allows for automated photography, which can be particularly useful for creating time-lapse videos. The choice of components, particularly those rated for 6 volts or higher, ensures compatibility and reliability in operation.

The assembly process begins with the design of the electronic circuit on a breadboard, allowing for easy modifications and testing before finalizing the layout on a printed circuit board. The use of a flow diagram during the software development phase aids in clarifying the logic and functionality of the code, which is essential for controlling the servo and timing the camera's shutter.

When constructing the adapter plate, precision is key, as it must securely hold both the camera and the servomotor in the correct alignment. The choice of materials, such as aluminum from scrap, not only keeps costs low but also provides a sturdy base for the assembly.

In outdoor applications, environmental considerations must be addressed. The use of a waterproof enclosure is vital for protecting sensitive components from moisture, while ensuring that the camera lens remains unobstructed. The configuration of the camera settings, such as resolution and flash, also plays a crucial role in the quality of the final output.

The final assembly involves careful soldering of components onto the PCB, with attention to detail in maintaining correct polarity and orientation. Testing the circuit with a multimeter ensures that all components are functioning as intended before sealing the enclosure. This project not only enhances technical skills but also provides an opportunity for creative expression through the art of photography.With a few basic hand tools and a digital camera, this programmable camera controller project is for you. By using components already available at home, costs may be kept to a minimum. A servomotor may be reused from a radio-controlled model and aluminium for the adaptor plate may be acquired from a manufacturer`s scrap bin.

Be sure to ask for permission first. All the suggested electronic bits need to have a 6-Volt rating or greater and may be bought from local retailers. This project combines creating an electronic circuit, building an adaptor plate so that the servo and the digital camera work together, and writing the software code.

Another interesting part of the project is being able to show people your video, produced from the still photographs recorded by this equipment you have created. Choosing the first subject is pretty easy. The author set a camera up in the family room of his own home, when celebrating a birthday. The camera was out of the way and soon forgotten until the video was viewed and resulted in lots of laughs.

To work effectively outdoors, protecting equipment is a little more difficult. For temporary shelter, umbrellas are great otherwise a showerproof container with a clear front should be used. Some food containers may be used but the interior must be kept dry or condensation may cause water droplets to form on cold equipment and lenses not a good environment for electronic gear.

To reduce condensation inside an enclosure you can fill the excess space with dry rags or bubble wrap. Be sure the lens and servo can still work properly. The camera should be set on the lowest resolution and the flash turned off. Make sure the horizon is horizontal and the verticals are vertical this also makes the video look a bit more professional.

Happy time lapsing! When starting to think about the software code, a flow diagram may help explain what waht you want to achieve. Remember there are often many different software solutions: Experiments with coding and components are carried out on a temporary `bread board` before a final design for the program and electronic circuit are decided.

Soldering sockets and hardware is one of the last operations in prototype development. Launch the PICAXE Programmer and create your own test program to check the functions of the LED and servo on the camera controller or copy the `timeLapseTest. bas` program below. `Notes to users are started with an apostrophe ` sign, which is ignored by the programme compiler and are not part of the code sent to the PICAXE IC.

The track side of the PCboard showing tracks cut with a 3 mm drill. For convenience on the prototype, a small component and jumper have been soldered on the track side of the board. In the final version, these parts should be connected on the top of the board. All components are populating the board and it sits on a battery box cover using Blu-tack to hold it on the lid.

The Blu-tack not only holds the circuit board, but provides clearance for the components on the track side. The battery box contains 4 x 2. 4 Ahr AA 1. 2 Volt rechargeable NiMH cells. Check to see you have all the components on the list or suitable substitutes. Where possible, verify with a multimeter to see that all the components work and that their values are correct.

On the track side of the printed circuit (PC) board, cut tracks to isolate the 8-pin IC socket legs. Next solder components such as resistors, jumpers, sockets and headers. Be sure polari 🔗 External reference

This programmable camera controller project offers a practical and engaging way to explore electronics and coding. The integration of a servomotor with a digital camera allows for automated photography, which can be particularly useful for creating time-lapse videos. The choice of components, particularly those rated for 6 volts or higher, ensures compatibility and reliability in operation.

The assembly process begins with the design of the electronic circuit on a breadboard, allowing for easy modifications and testing before finalizing the layout on a printed circuit board. The use of a flow diagram during the software development phase aids in clarifying the logic and functionality of the code, which is essential for controlling the servo and timing the camera's shutter.

When constructing the adapter plate, precision is key, as it must securely hold both the camera and the servomotor in the correct alignment. The choice of materials, such as aluminum from scrap, not only keeps costs low but also provides a sturdy base for the assembly.

In outdoor applications, environmental considerations must be addressed. The use of a waterproof enclosure is vital for protecting sensitive components from moisture, while ensuring that the camera lens remains unobstructed. The configuration of the camera settings, such as resolution and flash, also plays a crucial role in the quality of the final output.

The final assembly involves careful soldering of components onto the PCB, with attention to detail in maintaining correct polarity and orientation. Testing the circuit with a multimeter ensures that all components are functioning as intended before sealing the enclosure. This project not only enhances technical skills but also provides an opportunity for creative expression through the art of photography.With a few basic hand tools and a digital camera, this programmable camera controller project is for you. By using components already available at home, costs may be kept to a minimum. A servomotor may be reused from a radio-controlled model and aluminium for the adaptor plate may be acquired from a manufacturer`s scrap bin.

Be sure to ask for permission first. All the suggested electronic bits need to have a 6-Volt rating or greater and may be bought from local retailers. This project combines creating an electronic circuit, building an adaptor plate so that the servo and the digital camera work together, and writing the software code.

Another interesting part of the project is being able to show people your video, produced from the still photographs recorded by this equipment you have created. Choosing the first subject is pretty easy. The author set a camera up in the family room of his own home, when celebrating a birthday. The camera was out of the way and soon forgotten until the video was viewed and resulted in lots of laughs.

To work effectively outdoors, protecting equipment is a little more difficult. For temporary shelter, umbrellas are great otherwise a showerproof container with a clear front should be used. Some food containers may be used but the interior must be kept dry or condensation may cause water droplets to form on cold equipment and lenses not a good environment for electronic gear.

To reduce condensation inside an enclosure you can fill the excess space with dry rags or bubble wrap. Be sure the lens and servo can still work properly. The camera should be set on the lowest resolution and the flash turned off. Make sure the horizon is horizontal and the verticals are vertical this also makes the video look a bit more professional.

Happy time lapsing! When starting to think about the software code, a flow diagram may help explain what waht you want to achieve. Remember there are often many different software solutions: Experiments with coding and components are carried out on a temporary `bread board` before a final design for the program and electronic circuit are decided.

Soldering sockets and hardware is one of the last operations in prototype development. Launch the PICAXE Programmer and create your own test program to check the functions of the LED and servo on the camera controller or copy the `timeLapseTest. bas` program below. `Notes to users are started with an apostrophe ` sign, which is ignored by the programme compiler and are not part of the code sent to the PICAXE IC.

The track side of the PCboard showing tracks cut with a 3 mm drill. For convenience on the prototype, a small component and jumper have been soldered on the track side of the board. In the final version, these parts should be connected on the top of the board. All components are populating the board and it sits on a battery box cover using Blu-tack to hold it on the lid.

The Blu-tack not only holds the circuit board, but provides clearance for the components on the track side. The battery box contains 4 x 2. 4 Ahr AA 1. 2 Volt rechargeable NiMH cells. Check to see you have all the components on the list or suitable substitutes. Where possible, verify with a multimeter to see that all the components work and that their values are correct.

On the track side of the printed circuit (PC) board, cut tracks to isolate the 8-pin IC socket legs. Next solder components such as resistors, jumpers, sockets and headers. Be sure polari 🔗 External reference