Pull switch lights delay circuit 2

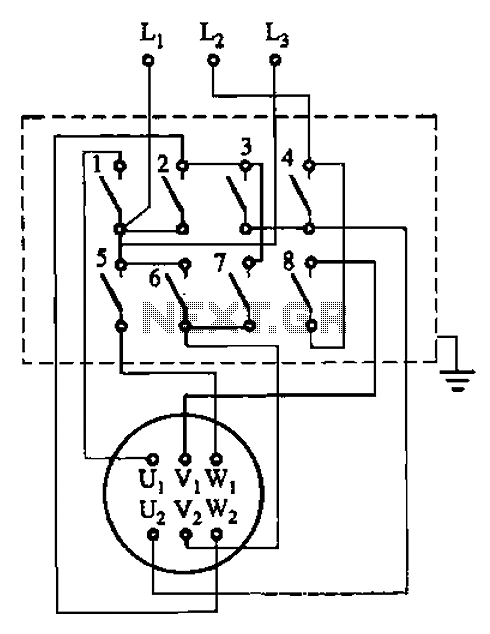

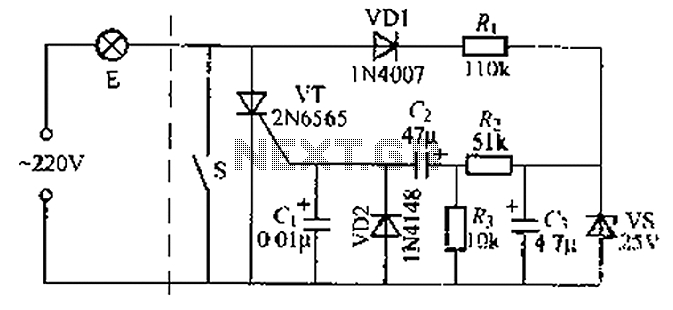

A delay circuit using an improved quenching lamp pull switch is described, focusing on its performance and the delay function in lighting control. The circuit exhibits a high degree of stability and reliability. When switch S is closed, the electronic circuits on the right remain inactive. When switch S is open, a 220V AC electric bulb is connected through component E, which includes a half-wave rectifier diode (VD1) and a capacitor (C) that limits the current. The capacitor charges quickly due to a small time constant. A 25V voltage regulator (VS) is connected in parallel with the capacitor, clamping the voltage across it to approximately 25V. This 25V DC voltage is applied through resistor R to the gate of a thyristor (VT), allowing the current to trigger the thyristor, which in turn activates the AC bulb, producing a dim light. After a period of several seconds, once the capacitor is fully charged, the thyristor loses its trigger current and turns off when the AC voltage crosses zero, resulting in the light extinguishing. The process can be repeated by closing switch S again, which allows the capacitor to discharge through resistor R and a variable resistor (VR2). The discharge time constant is small, enabling rapid discharge for the next cycle. The delay time for the lighting effect is primarily determined by the capacitor's charge time constant, which is approximately 40 seconds. Adjustments to the delay time can be made by varying the capacitance of capacitor C.

The described circuit utilizes a quenching lamp pull switch mechanism to create a controlled delay in lighting applications. The operational principle relies on the charging and discharging characteristics of the capacitor (C) in conjunction with the thyristor (VT) and associated components. Initially, when switch S is closed, the circuit remains inactive, preventing any current flow through the light bulb connected to E. Upon opening switch S, the AC voltage is applied to the circuit, allowing the diode (VD1) to rectify the input voltage, while the capacitor (C) begins to charge.

The design incorporates a 25V voltage regulator (VS) which ensures that the voltage across the capacitor does not exceed this limit, thus providing stable operation. The thyristor (VT) is triggered by the voltage across the capacitor via the resistor (R). Once triggered, the thyristor allows current to flow through the AC bulb, producing a dim light output. The gradual charging of the capacitor results in a delay before the thyristor is turned off, which occurs when the capacitor reaches full charge and the AC voltage crosses zero.

The circuit's ability to control the delay time is achieved by modifying the capacitance of capacitor C. A larger capacitance will increase the charge time, thereby extending the delay period, while a smaller capacitance will reduce it. The resistor R and variable resistor VR2 play crucial roles in the discharge process, allowing the stored charge in the capacitor to be released efficiently, preparing the circuit for the next activation cycle. Overall, this delay circuit is suitable for applications requiring precise timing in lighting control, ensuring both reliability and stability in operation.A delay by the improved quenching lamp pull switch, its performance and the example described delay lights care line switches, but the work of a high degree of stability and go od reliability. When S is closed, lights, electronic circuits on the right does not work. Ge lights, s open, 220V AC electric bulb through E, a half-wave rectifier diode VD1, foot t buck limit the flow of C. Charged by the charging time constant dry small, G soon full charge. c, in parallel across a 25V regulator vs. So C, both ends of the business flow voltage is clamped at about 25V. This fork 25V DC voltage through R, VT to the cathode gate capacitance [1. Yun electricity, this allows the electric current is triggered thyristor VT iU flows, thus opening VT is triggered.

AC bulb half crossing through, so see the light bulb E send weak lighting. After about tens of seconds, c charge is full, VT lost trigger current, when the AC zero crossing that is turned off, the light goes off. Turn on the lights again, s closed, lights. Then s voltage drop across zero, C, and stored charge by R. vr2 venting, the discharge time constant is small, electric charge is done and soon put out for the next spider ready for the delay circuit delay lights depends on the length of time the main calyx (j charging electric call the time constant of the road, using data illustrating the delay time is about 40s.

to extend or shrink when cerium peaks J, canthus can increase or decrease the capacitance C. capacity.

The described circuit utilizes a quenching lamp pull switch mechanism to create a controlled delay in lighting applications. The operational principle relies on the charging and discharging characteristics of the capacitor (C) in conjunction with the thyristor (VT) and associated components. Initially, when switch S is closed, the circuit remains inactive, preventing any current flow through the light bulb connected to E. Upon opening switch S, the AC voltage is applied to the circuit, allowing the diode (VD1) to rectify the input voltage, while the capacitor (C) begins to charge.

The design incorporates a 25V voltage regulator (VS) which ensures that the voltage across the capacitor does not exceed this limit, thus providing stable operation. The thyristor (VT) is triggered by the voltage across the capacitor via the resistor (R). Once triggered, the thyristor allows current to flow through the AC bulb, producing a dim light output. The gradual charging of the capacitor results in a delay before the thyristor is turned off, which occurs when the capacitor reaches full charge and the AC voltage crosses zero.

The circuit's ability to control the delay time is achieved by modifying the capacitance of capacitor C. A larger capacitance will increase the charge time, thereby extending the delay period, while a smaller capacitance will reduce it. The resistor R and variable resistor VR2 play crucial roles in the discharge process, allowing the stored charge in the capacitor to be released efficiently, preparing the circuit for the next activation cycle. Overall, this delay circuit is suitable for applications requiring precise timing in lighting control, ensuring both reliability and stability in operation.A delay by the improved quenching lamp pull switch, its performance and the example described delay lights care line switches, but the work of a high degree of stability and go od reliability. When S is closed, lights, electronic circuits on the right does not work. Ge lights, s open, 220V AC electric bulb through E, a half-wave rectifier diode VD1, foot t buck limit the flow of C. Charged by the charging time constant dry small, G soon full charge. c, in parallel across a 25V regulator vs. So C, both ends of the business flow voltage is clamped at about 25V. This fork 25V DC voltage through R, VT to the cathode gate capacitance [1. Yun electricity, this allows the electric current is triggered thyristor VT iU flows, thus opening VT is triggered.

AC bulb half crossing through, so see the light bulb E send weak lighting. After about tens of seconds, c charge is full, VT lost trigger current, when the AC zero crossing that is turned off, the light goes off. Turn on the lights again, s closed, lights. Then s voltage drop across zero, C, and stored charge by R. vr2 venting, the discharge time constant is small, electric charge is done and soon put out for the next spider ready for the delay circuit delay lights depends on the length of time the main calyx (j charging electric call the time constant of the road, using data illustrating the delay time is about 40s.

to extend or shrink when cerium peaks J, canthus can increase or decrease the capacitance C. capacity.