RC Controlled Forklift robot

The Automatic Forklift System (AFS) is engineered to enhance the safety and efficiency of warehouse stocking processes. Traditional manually operated forklifts pose injury risks to employees. The Automatic Forklift System (AFS) aims to mitigate these hazards.

The Automatic Forklift System (AFS) integrates advanced technologies such as sensors, cameras, and artificial intelligence to facilitate autonomous operation in warehouse environments. The system utilizes a network of LIDAR and ultrasonic sensors to navigate and map the warehouse layout, allowing for real-time obstacle detection and avoidance. This ensures safe movement around personnel and equipment.

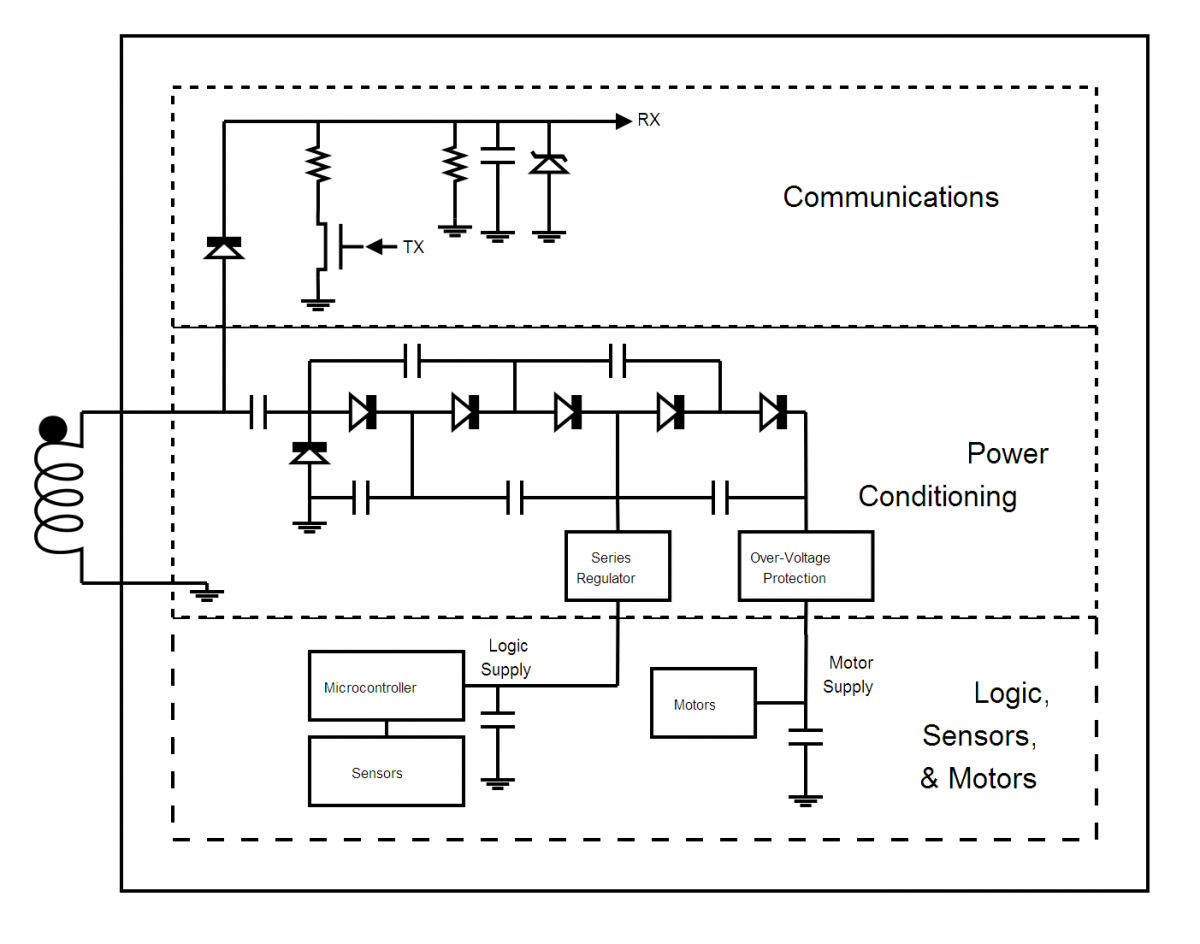

The AFS is equipped with a robust control unit that processes data from the sensors to make instant decisions regarding navigation and load handling. It employs a combination of electric motors and hydraulic systems to lift and transport goods efficiently. The system can be programmed to follow specific routes or dynamically adjust its path based on real-time conditions.

Safety features are paramount in the design of the AFS. Emergency stop buttons are strategically placed, and the system is designed to halt operations immediately if a human is detected in its path. Additionally, the AFS can communicate with other warehouse systems to coordinate activities and optimize workflow.

Power management is another critical aspect of the AFS. The system operates on rechargeable batteries that provide sufficient runtime for continuous operation. Battery management systems monitor charge levels and optimize charging cycles to extend battery life.

In summary, the Automatic Forklift System (AFS) represents a significant advancement in warehouse automation, prioritizing safety and efficiency through sophisticated technology and design. Its implementation can lead to reduced labor costs, minimized injury risks, and increased productivity in warehouse operations.The Automatic Forklift System (AFS) is designed to make the process of stocking warehouses safer and more efficient. With current manually operated forklifts, employees are at risk of injury. The Automatic Forklift System (AFS) is designed to make the process of stocking warehouses safer and more efficient..

🔗 External reference

The Automatic Forklift System (AFS) integrates advanced technologies such as sensors, cameras, and artificial intelligence to facilitate autonomous operation in warehouse environments. The system utilizes a network of LIDAR and ultrasonic sensors to navigate and map the warehouse layout, allowing for real-time obstacle detection and avoidance. This ensures safe movement around personnel and equipment.

The AFS is equipped with a robust control unit that processes data from the sensors to make instant decisions regarding navigation and load handling. It employs a combination of electric motors and hydraulic systems to lift and transport goods efficiently. The system can be programmed to follow specific routes or dynamically adjust its path based on real-time conditions.

Safety features are paramount in the design of the AFS. Emergency stop buttons are strategically placed, and the system is designed to halt operations immediately if a human is detected in its path. Additionally, the AFS can communicate with other warehouse systems to coordinate activities and optimize workflow.

Power management is another critical aspect of the AFS. The system operates on rechargeable batteries that provide sufficient runtime for continuous operation. Battery management systems monitor charge levels and optimize charging cycles to extend battery life.

In summary, the Automatic Forklift System (AFS) represents a significant advancement in warehouse automation, prioritizing safety and efficiency through sophisticated technology and design. Its implementation can lead to reduced labor costs, minimized injury risks, and increased productivity in warehouse operations.The Automatic Forklift System (AFS) is designed to make the process of stocking warehouses safer and more efficient. With current manually operated forklifts, employees are at risk of injury. The Automatic Forklift System (AFS) is designed to make the process of stocking warehouses safer and more efficient..

🔗 External reference