relay circuits

Remove the 6 mm screw that secures the lower rear fairing cover. This cover is the black plastic piece to which the spark plug protectors are attached. Only the machine screw should be removed; do not detach the lower rear fairing covers. Fabricate "L" brackets from the mending plates to mount the horns. The mending plates can be bent in a vice, and a couple of the holes can be enlarged to fit the 6 mm machine screws. Mount the horns on the "L" brackets using the fittings provided in the Fiamm Horn kit and attach the "L" brackets to the inside of the lower fairing covers using the 6x30 mm machine screws. The shorter air horn should be mounted on the left front side to allow more space for the relay, which will also be installed on the left front side, while the longer horn is to be mounted on the right front side. Secure the brackets with washers, lock washers, and nuts. Cut a piece of ethafoam to the height of the 12-volt air compressor. Split the foam and wrap it around the compressor, securing it with duct tape if desired. The foam serves two purposes: it protects the 12-volt air compressor housing from vibrations and prevents scratching of the frame down tube. Identify the terminals on the 12-volt relay included in the Fiamm Air Horn Kit. Since the horns draw significantly more power (8 amps) than the stock horns, a relay is necessary to switch battery power directly to the horns, thereby reducing wear on the horn switch. Identifying the terminals on the 12-volt relay may require a magnifying glass because they are small and etched on the black plastic housing adjacent to the pins. Mount the relay using the bolt that secured the left front horn. If there is insufficient clearance when reinstalling the lower left fairing, the relay may need to be relocated slightly towards the rear of the bike. The relay can be secured using a cable tie. Route the fuel line from the 12-volt air compressor to the "Y" fitting provided in the horn kit, and then route the tubing from the "Y" fitting to each horn. Use small hose clamps to secure the fuel line tubing at all connections. Attach a solderless terminal connector to one end of the inline fuse holder and connect the other end of the fuse holder to the 14-gauge wire using a butt connector. This terminal connector will be connected to the positive terminal of the battery. It is essential to place the inline fuse as close to the battery as possible for optimal protection. Route the two wires to the front of the bike near the relay switch and the 12-volt air compressor, connecting them using solderless connectors according to the provided wiring diagram. It is crucial to note that the wiring diagram included with the Fiamm Air Horn package may not be applicable to this specific bike model. Following the correct wiring solution is essential for proper installation.

The circuit design involves integrating a 12-volt air compressor with dual air horns, necessitating careful consideration of power management and physical installation. The use of an "L" bracket structure allows for a secure mounting of the horns while maintaining access to other components. The selection of mending plates for bracket fabrication provides a robust solution for horn attachment, ensuring stability during operation.

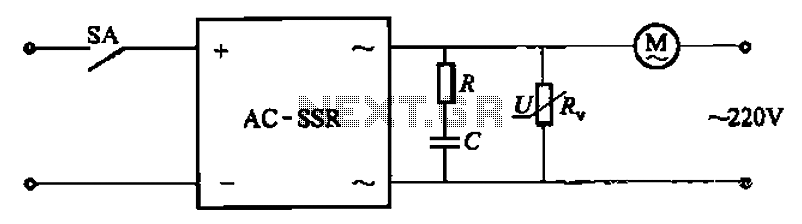

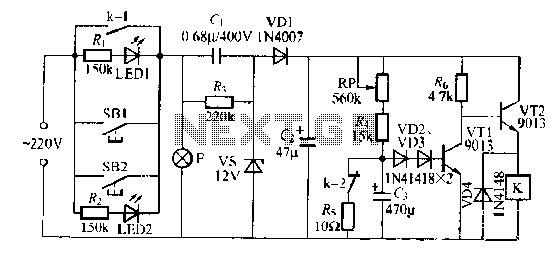

The relay serves as a critical component in the circuit, allowing high-current horns to operate without overloading the existing horn switch. The relay's terminals, though small, must be correctly identified and connected to ensure reliable operation. The relocation of the relay might be necessary depending on the available space, thus highlighting the importance of a flexible installation approach.

The use of ethafoam around the compressor not only dampens vibrations but also serves as a protective barrier against potential damage, emphasizing the importance of physical protection in electronic installations. The routing of the fuel line and tubing must be executed with care to prevent leaks and ensure efficient operation of the air horns. The inclusion of inline fuses is a standard practice in automotive and motorcycle circuits, providing an additional layer of safety by preventing potential damage from short circuits.

Overall, this installation requires attention to detail in both the mechanical and electrical aspects, ensuring that the final assembly operates efficiently and safely within the vehicle's existing framework. Proper adherence to the provided wiring diagram and careful handling of components will yield a successful integration of the air horns and compressor into the motorcycle's electrical system.Remove the 6 mm screw holding on the lower rear fairing cover. This is the black plastic piece the spark plug protectors are attached to. Do not remove the lower rear fairing covers, only the machine screw. Fabricate "L" brackets from the mending plates to mount your horns. I bent my mending plates in a vice and enlarged a couple of the holes to f it the 6 mm machine screws I used. Mount the horns on the "L" brackets with fittings supplied in the Fiamm Horn kit and mount the "L" brackets on the inside of the lower fairing covers to the back of the 6x30 mm machine screws. Mount the shorter air horn on the left front side (to leave more room for the relay which also get installed on the left front side) and the longer one on the right front side.

Secure the brackets in place with washers, lockwashers and nuts. Cut a piece of ethafoam the height of the 12 volt air compressor. Split the foam and wrap it around the compressor. Secure with duct tape if you like. The purpose of the foam is two fold. It helps to protect the 12 volt air compressor housing from vibration and scratching of the frame down tube. Identify the terminals on the 12 volt relay supplied in the Fiamm Air Horn Kit. Because the horns draw a lot more power (8 amps) than the stock horns we need to use a relay to switch battery power directly to the horns.

This will save wear and tear on the horn switch. Identifying the terminals on the 12 volt relay may require a magnifying glass because they are very small and etched on the black plastic housing of the relay adjacent to the pins. Mount the relay with the bolt that was used to secure the left front horn. If there is insufficient clearance when you re-install the lower left fairing you may have to relocate the relay slightly towards the rear of the bike.

I relocated my relay and secured it using a cable tie. Route the fuel line from the 12 volt air compressor to the "Y" fitting provided in the horn kit. Route the tubing from the "Y" fitting to each of the horns. Use the small hose clamps to secure the fuel line tubing at all connections. Put a solderless terminal connector on one end of the in line fuse holder. Connect the other end of the fuse holder to the 14 gauge wire using a butt connector. You will be connecting the terminal connector to the positive terminal of the battery. Remember to place the in-line fuse as close to the battery as possible for best protection. Route the two wires to the front of the bike in the vicinity of the relay switch and 12 volt air compressor and connect them using solderless connectors following the directions in the attached wiring diagram. This is important: The wiring diagram shown on the Fiamm Air Horn package will not work on our bikes.

It took some time before I found out the solution. Follow my solution in the wiring diagram exactly. This is important too: When I removed the wires from the stock horns there was a 🔗 External reference

The circuit design involves integrating a 12-volt air compressor with dual air horns, necessitating careful consideration of power management and physical installation. The use of an "L" bracket structure allows for a secure mounting of the horns while maintaining access to other components. The selection of mending plates for bracket fabrication provides a robust solution for horn attachment, ensuring stability during operation.

The relay serves as a critical component in the circuit, allowing high-current horns to operate without overloading the existing horn switch. The relay's terminals, though small, must be correctly identified and connected to ensure reliable operation. The relocation of the relay might be necessary depending on the available space, thus highlighting the importance of a flexible installation approach.

The use of ethafoam around the compressor not only dampens vibrations but also serves as a protective barrier against potential damage, emphasizing the importance of physical protection in electronic installations. The routing of the fuel line and tubing must be executed with care to prevent leaks and ensure efficient operation of the air horns. The inclusion of inline fuses is a standard practice in automotive and motorcycle circuits, providing an additional layer of safety by preventing potential damage from short circuits.

Overall, this installation requires attention to detail in both the mechanical and electrical aspects, ensuring that the final assembly operates efficiently and safely within the vehicle's existing framework. Proper adherence to the provided wiring diagram and careful handling of components will yield a successful integration of the air horns and compressor into the motorcycle's electrical system.Remove the 6 mm screw holding on the lower rear fairing cover. This is the black plastic piece the spark plug protectors are attached to. Do not remove the lower rear fairing covers, only the machine screw. Fabricate "L" brackets from the mending plates to mount your horns. I bent my mending plates in a vice and enlarged a couple of the holes to f it the 6 mm machine screws I used. Mount the horns on the "L" brackets with fittings supplied in the Fiamm Horn kit and mount the "L" brackets on the inside of the lower fairing covers to the back of the 6x30 mm machine screws. Mount the shorter air horn on the left front side (to leave more room for the relay which also get installed on the left front side) and the longer one on the right front side.

Secure the brackets in place with washers, lockwashers and nuts. Cut a piece of ethafoam the height of the 12 volt air compressor. Split the foam and wrap it around the compressor. Secure with duct tape if you like. The purpose of the foam is two fold. It helps to protect the 12 volt air compressor housing from vibration and scratching of the frame down tube. Identify the terminals on the 12 volt relay supplied in the Fiamm Air Horn Kit. Because the horns draw a lot more power (8 amps) than the stock horns we need to use a relay to switch battery power directly to the horns.

This will save wear and tear on the horn switch. Identifying the terminals on the 12 volt relay may require a magnifying glass because they are very small and etched on the black plastic housing of the relay adjacent to the pins. Mount the relay with the bolt that was used to secure the left front horn. If there is insufficient clearance when you re-install the lower left fairing you may have to relocate the relay slightly towards the rear of the bike.

I relocated my relay and secured it using a cable tie. Route the fuel line from the 12 volt air compressor to the "Y" fitting provided in the horn kit. Route the tubing from the "Y" fitting to each of the horns. Use the small hose clamps to secure the fuel line tubing at all connections. Put a solderless terminal connector on one end of the in line fuse holder. Connect the other end of the fuse holder to the 14 gauge wire using a butt connector. You will be connecting the terminal connector to the positive terminal of the battery. Remember to place the in-line fuse as close to the battery as possible for best protection. Route the two wires to the front of the bike in the vicinity of the relay switch and 12 volt air compressor and connect them using solderless connectors following the directions in the attached wiring diagram. This is important: The wiring diagram shown on the Fiamm Air Horn package will not work on our bikes.

It took some time before I found out the solution. Follow my solution in the wiring diagram exactly. This is important too: When I removed the wires from the stock horns there was a 🔗 External reference