remote control circuit

This is a universal remote control that was constructed using 1KB of memory. It operates with televisions utilizing the RC5, RC80, and NEC protocols, which cover the majority of TV models. The remote has an effective range of approximately 40 meters and functions at angles up to 60 degrees. The initial step involved using ExpressSCH to design a schematic for the circuit necessary to power the microprocessor and LEDs. Subsequently, Google SketchUp was employed to create a 3D model of the remote's appearance. Using ExpressPCB, the components were arranged in a practical layout that corresponded with the mock-up. All required component values, including resistance for resistors and current for LEDs, were calculated and the parts were ordered from Digikey.com. A circuit board coated with photosensitive chemicals was used to print the circuit onto the board through a multi-step chemical process. After trimming the board to size, all components were soldered in place. The programming and debugging phase consumed the majority of the project time, utilizing MPLAB for programming along with a multimeter, digital oscilloscope, CHRP board, and MPLAB SIM for debugging.

The universal remote control is designed to provide compatibility with a wide range of television models, utilizing widely adopted protocols such as RC5, RC80, and NEC. The microcontroller at the heart of the design is programmed to handle infrared (IR) signal generation and reception, enabling it to communicate effectively with various television sets. The effective range of 40 meters ensures that the remote can operate from a significant distance, while the 60-degree angle of effectiveness allows for flexibility in user positioning.

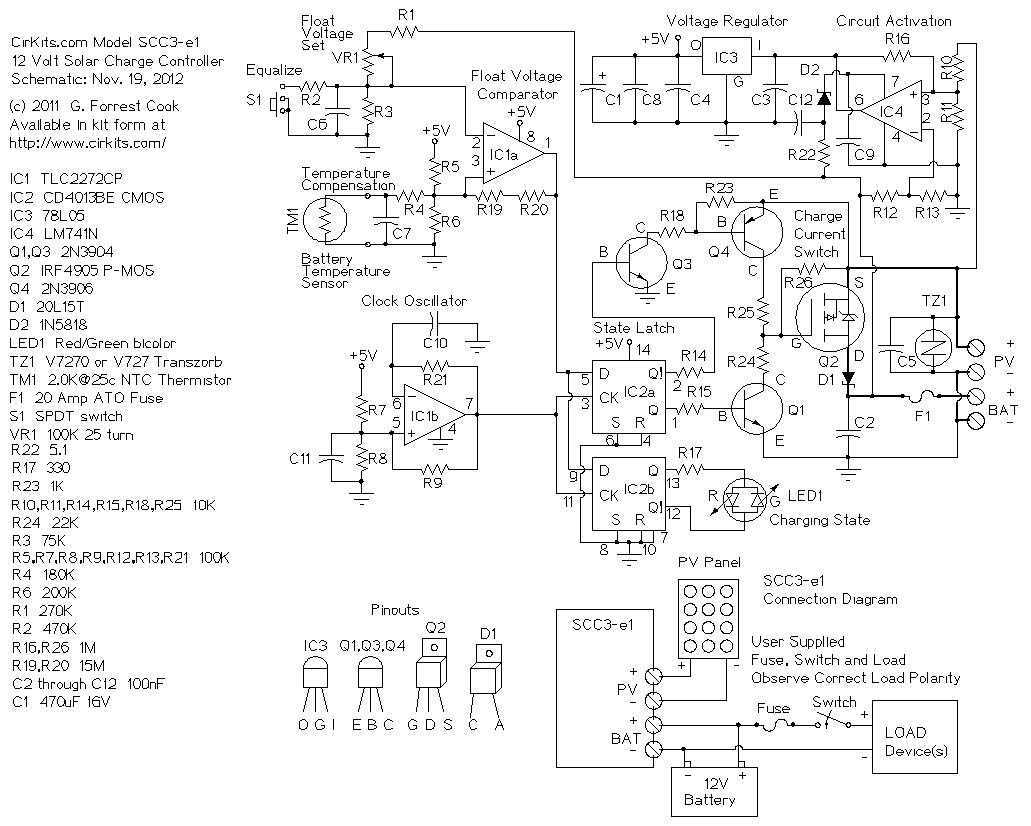

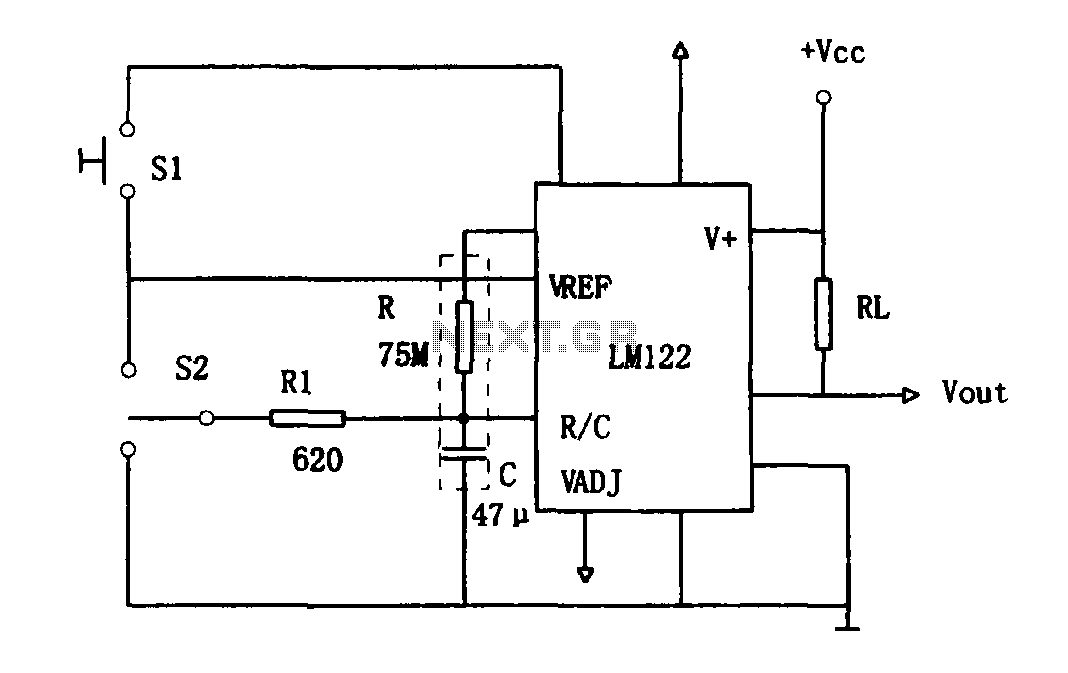

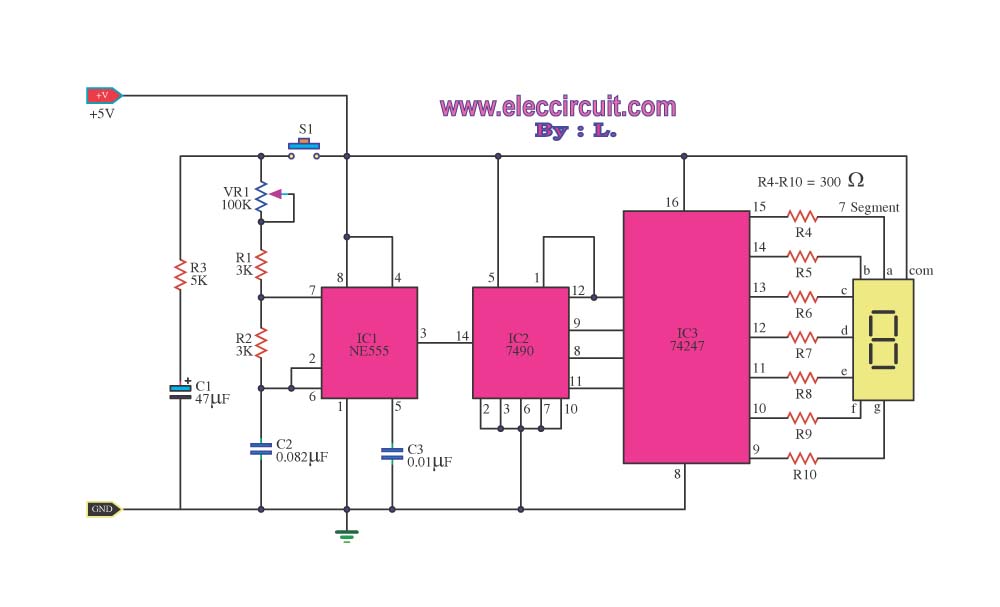

The schematic design phase, executed in ExpressSCH, includes the essential components such as the microcontroller, resistors, capacitors, and LEDs. The microcontroller is powered by a regulated voltage supply, ensuring stable operation. Resistors are strategically placed to limit current to the LEDs and to set appropriate operating conditions for other components. The schematic is carefully laid out to minimize interference and ensure reliable signal transmission.

The 3D modeling in Google SketchUp aids in visualizing the remote's physical design, allowing for ergonomic considerations and user interface layout, such as button placement and display positioning. The transition to ExpressPCB for the printed circuit board (PCB) layout involves arranging components in a manner that facilitates efficient signal flow and minimizes trace lengths, which is crucial for high-frequency applications like IR communication.

The manufacturing process includes the use of photosensitive chemicals for etching the PCB, followed by precise cutting and soldering of components. This method ensures a high-quality finish and reliable connections. The debugging process is critical, as it involves testing the functionality of the remote control, verifying the correctness of the programmed code, and ensuring that all components operate as intended. The use of tools such as a multimeter and digital oscilloscope provides valuable insights into the performance of the circuit, while MPLAB SIM allows for simulation of the microcontroller's operation under various conditions.

Overall, the development of this universal remote control showcases a comprehensive approach to electronic design, integrating schematic design, physical modeling, PCB fabrication, and thorough testing to create a functional and user-friendly device.This is a universal remote control I built. The entire thing was programmed with just 1KBof memory, and works with TV`s using the RC 5, RC 80, and NEC protocols (most TV`s). Its effective range is about 40m, and is effective at angles up to 60 degrees. I began by using ExpressSCH to lay out a schematic of the circuit required to power the micropro cessor and LEDs. I used I then usedGoogleSketchUpto create amocked up3D model of the remotes appearance. Using ExpressPCB, I then arranged the parts in a real world design that would fit the mock up. I calculated all the required values for parts, such as resistance for the resistors, and current for the LEDs, thenorderedthem from Digikey. com. I then used circuit board coated with photosensitive chemicals to print my circuit onto the board, through a multi-step chemical process.

After cutting the board down to size, I soldered all the parts in. The process of programming and debugging required the largest majority of time. I programmed in MPLAB, and used, a multimeter, digitaloscilloscope, CHRP board (see here ), and MPLAB SIM to debug. 🔗 External reference

The universal remote control is designed to provide compatibility with a wide range of television models, utilizing widely adopted protocols such as RC5, RC80, and NEC. The microcontroller at the heart of the design is programmed to handle infrared (IR) signal generation and reception, enabling it to communicate effectively with various television sets. The effective range of 40 meters ensures that the remote can operate from a significant distance, while the 60-degree angle of effectiveness allows for flexibility in user positioning.

The schematic design phase, executed in ExpressSCH, includes the essential components such as the microcontroller, resistors, capacitors, and LEDs. The microcontroller is powered by a regulated voltage supply, ensuring stable operation. Resistors are strategically placed to limit current to the LEDs and to set appropriate operating conditions for other components. The schematic is carefully laid out to minimize interference and ensure reliable signal transmission.

The 3D modeling in Google SketchUp aids in visualizing the remote's physical design, allowing for ergonomic considerations and user interface layout, such as button placement and display positioning. The transition to ExpressPCB for the printed circuit board (PCB) layout involves arranging components in a manner that facilitates efficient signal flow and minimizes trace lengths, which is crucial for high-frequency applications like IR communication.

The manufacturing process includes the use of photosensitive chemicals for etching the PCB, followed by precise cutting and soldering of components. This method ensures a high-quality finish and reliable connections. The debugging process is critical, as it involves testing the functionality of the remote control, verifying the correctness of the programmed code, and ensuring that all components operate as intended. The use of tools such as a multimeter and digital oscilloscope provides valuable insights into the performance of the circuit, while MPLAB SIM allows for simulation of the microcontroller's operation under various conditions.

Overall, the development of this universal remote control showcases a comprehensive approach to electronic design, integrating schematic design, physical modeling, PCB fabrication, and thorough testing to create a functional and user-friendly device.This is a universal remote control I built. The entire thing was programmed with just 1KBof memory, and works with TV`s using the RC 5, RC 80, and NEC protocols (most TV`s). Its effective range is about 40m, and is effective at angles up to 60 degrees. I began by using ExpressSCH to lay out a schematic of the circuit required to power the micropro cessor and LEDs. I used I then usedGoogleSketchUpto create amocked up3D model of the remotes appearance. Using ExpressPCB, I then arranged the parts in a real world design that would fit the mock up. I calculated all the required values for parts, such as resistance for the resistors, and current for the LEDs, thenorderedthem from Digikey. com. I then used circuit board coated with photosensitive chemicals to print my circuit onto the board, through a multi-step chemical process.

After cutting the board down to size, I soldered all the parts in. The process of programming and debugging required the largest majority of time. I programmed in MPLAB, and used, a multimeter, digitaloscilloscope, CHRP board (see here ), and MPLAB SIM to debug. 🔗 External reference