Reversing the operation of the two reverse brake circuit

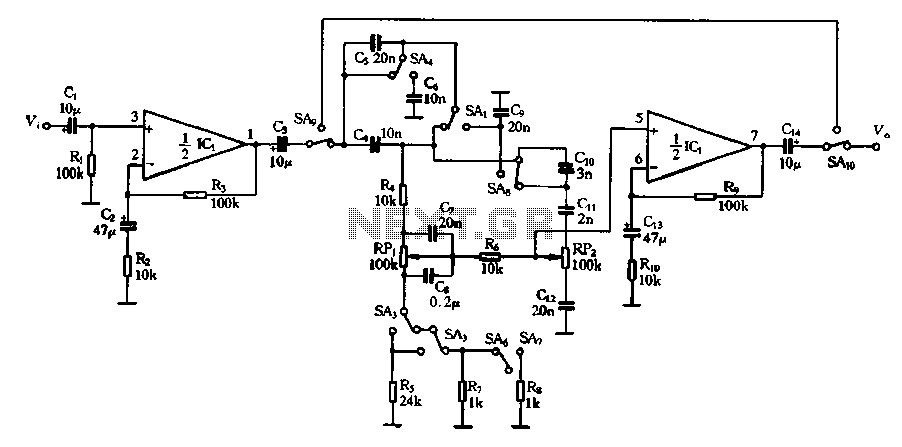

The circuit shown in Figure 3-129 is the C650-2 lathe brake control circuit, utilizing a speed control relay.

The C650-2 lathe brake control circuit is designed to manage the braking mechanism of a lathe machine effectively. This circuit incorporates a speed control relay that plays a crucial role in modulating the braking response based on the operational speed of the lathe.

The primary components of this circuit include the speed control relay, which is responsible for detecting the rotational speed of the lathe spindle. When the spindle speed reaches a predetermined threshold, the relay activates, allowing for the application of the brake. This ensures that the braking force is applied smoothly and efficiently, preventing abrupt stops that could damage the workpiece or the machine itself.

In addition to the speed control relay, the circuit may also include safety features such as limit switches that ensure the brake is only engaged when the lathe is in a safe operational state. The control logic can be implemented using a combination of mechanical relays or a programmable logic controller (PLC), depending on the complexity required for the application.

Wiring for the circuit should be laid out to minimize interference and ensure reliable operation. Proper grounding and the use of appropriate gauge wires are essential to handle the current loads associated with the brake system. Additionally, protective components such as fuses or circuit breakers should be integrated to safeguard against overcurrent situations.

Overall, the C650-2 lathe brake control circuit exemplifies a well-designed system that integrates speed monitoring and braking control, enhancing both the safety and efficiency of lathe operations. Circuit shown in Figure 3-129. The circuit is C650-2 lathe brake control circuit. Kv using speed control relay.

The C650-2 lathe brake control circuit is designed to manage the braking mechanism of a lathe machine effectively. This circuit incorporates a speed control relay that plays a crucial role in modulating the braking response based on the operational speed of the lathe.

The primary components of this circuit include the speed control relay, which is responsible for detecting the rotational speed of the lathe spindle. When the spindle speed reaches a predetermined threshold, the relay activates, allowing for the application of the brake. This ensures that the braking force is applied smoothly and efficiently, preventing abrupt stops that could damage the workpiece or the machine itself.

In addition to the speed control relay, the circuit may also include safety features such as limit switches that ensure the brake is only engaged when the lathe is in a safe operational state. The control logic can be implemented using a combination of mechanical relays or a programmable logic controller (PLC), depending on the complexity required for the application.

Wiring for the circuit should be laid out to minimize interference and ensure reliable operation. Proper grounding and the use of appropriate gauge wires are essential to handle the current loads associated with the brake system. Additionally, protective components such as fuses or circuit breakers should be integrated to safeguard against overcurrent situations.

Overall, the C650-2 lathe brake control circuit exemplifies a well-designed system that integrates speed monitoring and braking control, enhancing both the safety and efficiency of lathe operations. Circuit shown in Figure 3-129. The circuit is C650-2 lathe brake control circuit. Kv using speed control relay.