Rolling Shutter Motor Control

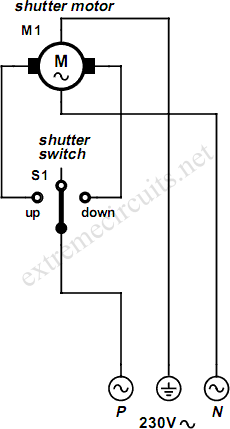

An electrically operated rolling shutter typically features a standard control panel equipped with a three-position switch that allows for up, down, and stop functions.

The electrically operated rolling shutter system is designed to provide convenient control over the opening and closing of the shutter. The core component of this system is the control panel, which houses a three-position switch. This switch functions in three distinct modes: 'up' for raising the shutter, 'down' for lowering it, and 'stop' to halt the operation at any desired position.

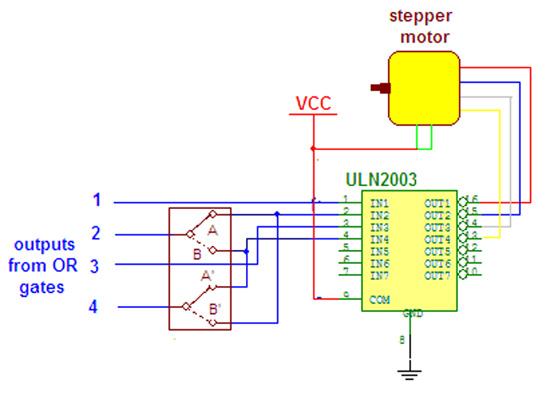

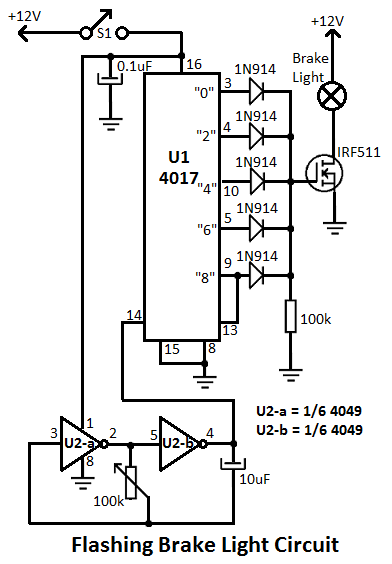

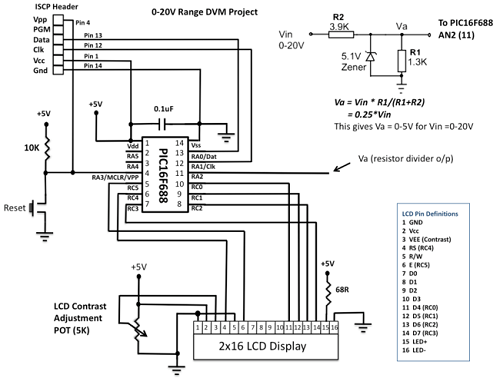

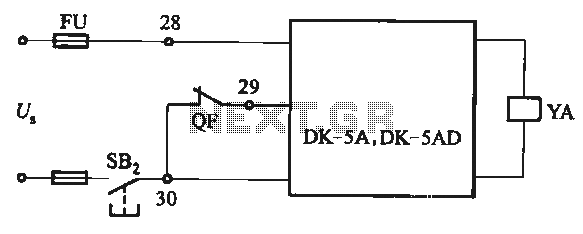

In a typical schematic, the power supply is connected to the control panel, which is integrated with a motor responsible for the movement of the shutter. The motor is often a DC or AC type, depending on the application requirements. The control panel’s switch connects to a relay or a motor driver circuit that regulates the direction of the motor based on the switch position.

When the 'up' position is selected, the relay energizes the motor in one direction, allowing the shutter to ascend. Conversely, selecting the 'down' position reverses the motor's direction, enabling the shutter to descend. The 'stop' position interrupts the power supply to the motor, effectively pausing the shutter's movement.

In addition to the basic functionality, safety features such as limit switches may be incorporated into the design. These switches detect the fully opened or closed positions of the shutter, automatically cutting off power to the motor to prevent damage from over-travel.

For advanced applications, the system may also include remote control capabilities, integrating wireless communication modules such as RF or Wi-Fi, allowing for operation from a distance. Overall, the electrically operated rolling shutter system enhances convenience and security, making it suitable for residential and commercial applications.An electrically operated rolling shutter usually has a standard control panel with a three-position switch: up, down and stop. If you would like to automa.. 🔗 External reference

The electrically operated rolling shutter system is designed to provide convenient control over the opening and closing of the shutter. The core component of this system is the control panel, which houses a three-position switch. This switch functions in three distinct modes: 'up' for raising the shutter, 'down' for lowering it, and 'stop' to halt the operation at any desired position.

In a typical schematic, the power supply is connected to the control panel, which is integrated with a motor responsible for the movement of the shutter. The motor is often a DC or AC type, depending on the application requirements. The control panel’s switch connects to a relay or a motor driver circuit that regulates the direction of the motor based on the switch position.

When the 'up' position is selected, the relay energizes the motor in one direction, allowing the shutter to ascend. Conversely, selecting the 'down' position reverses the motor's direction, enabling the shutter to descend. The 'stop' position interrupts the power supply to the motor, effectively pausing the shutter's movement.

In addition to the basic functionality, safety features such as limit switches may be incorporated into the design. These switches detect the fully opened or closed positions of the shutter, automatically cutting off power to the motor to prevent damage from over-travel.

For advanced applications, the system may also include remote control capabilities, integrating wireless communication modules such as RF or Wi-Fi, allowing for operation from a distance. Overall, the electrically operated rolling shutter system enhances convenience and security, making it suitable for residential and commercial applications.An electrically operated rolling shutter usually has a standard control panel with a three-position switch: up, down and stop. If you would like to automa.. 🔗 External reference