Scope Probe Adapter

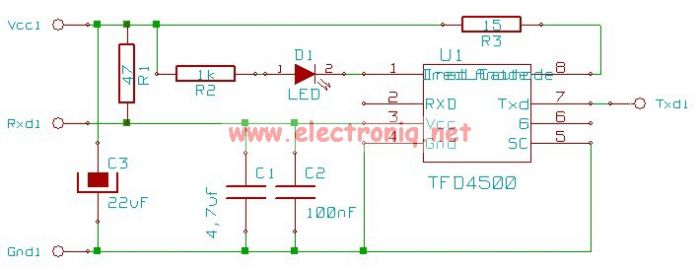

The capacitance between the wire and the probe would form a capacitive voltage divider with the probe's input capacitance, and at frequencies significantly higher than the low frequency roll off created by the probe's input capacitance and the probe's resistance, the waveform would be faithfully reproduced, although it would have a reduced amplitude. The circuit given here presents about a 2 pF load to the circuit and capacitively loads the circuit measurably less than the X100 voltage probe (A Stack CP-241) often used for this sort of thing.

More: To make a X10 capacitive attenuator, simply select a variable capacitor, C2 that has an adjustment range that includes the capacitance, that when added to Cin, the input capacitance of the scope probe you are going to use with it, is nine times that of the coupling capacitor. In this circuit, the coupling capacitor, C1, is 2 pF and the scope probe's input capacitance is about 16 pF, so C2 is

C2 = (9X C1) - Cin

C2 = (9 X 2 pF) - 16 pF

C2 = 2 pF

This set of values puts 90% of the voltage across C1 and 10% across C2 and the scope probe. This also works for higher attenuations, but since signals of a few volts or less are typically used, X10 is about as high as needed.

Construction and Calibration

This circuit is constructed on a small piece of pre-punched fiberglass board with a plated metalization pattern. The leads are kept short to minimize stray reactances. A couple of centimeters of bare #30 tinned copper wire serves as the probe. A small hook at the end allows the probe to "hang" on component leads. Occasionally, the tip of the wire is soldered to the circuit under test.

A short length of hookup wire connects the adapter to an alligator clip, which provides the ground contact for the circuit under test. It is advisable to keep this wire as short as possible. For frequencies above 50 MHz, soldering a short piece of wire, approximately 1 cm long, directly from the adapter's ground to the circuit under test is recommended.

Two pieces of nickel-plated paper clip are soldered to the board to serve as connection points for the scope probe and the probe's ground clip. While a connector that accepts the probe body without the probe tip would be ideal, nickel-plated paper clips are used as a substitute in this case. Solder flux, in addition to that in the flux core solder, is applied to the paper clip during soldering to enhance the connection quality.

This design effectively creates a X10 capacitive attenuator, ensuring minimal loading on the circuit under test while maintaining signal integrity at elevated frequencies.The capacitance between the wire and the probe would form a capacitive voltage divider with the probe's input capacitance, and at frequencies significantly higher than the low frequency roll off created by the probe's input capacitance and the probe's resistance, the wave form would be faithfully reproduced, although it would have a reduced amplitude. The circuit give here, presents about a 2 pf load to the circuit, and capacitively loads the circuit measurably less than the X100 voltage probe (A Stack CP-241) I often use for this sort of thing.

To make a X10 capacitive attenuator, simply select a variable capacitor, C2 that has an adjustment range that includes the capacitance, that when added to Cin, the input capacitance of the scope probe you are going to use with it, is nine times that of the coupling capacitor. In this circuit, the coupling capacitor, C1. is 2 pf and the scope probe's input capacitance is about 16 pf, so C2 is C2 = (9X C1) - Cin C2 =( 9 X 2 pf ) -16 pf C= 2pf This set of values puts 90% of the voltage across C1 and 10% across C2 and the scope probe.

This also works for higher attenuations, but since I am working with signals of a few volts or less, X10 is about as high as I need to go. Construction and Calibration I built this on a small piece of pre-punched fiberglass board with a plated metalization pattern.

The leads are all short to minimize stray reactances. A couple cm of bare #30 tinned copper wire serves as the probe. A small hook at the end lets me "hang" the probe on component leads. I also occasionally solder the tip of the wire to the circuit under test. A short length of hookup wire makes the ground connection from the adapter to an alligator clip which makes the ground contact for the circuit under test. The shorter the better. For frequencies above 50 MHz, it would be much better to just solder a short piece of wire, about 1 cm long, from the adapter's ground to the circuit under test.

Two pieces of nickel plated paper clip are soldered to the board to serve as connection points for the scope probe and the probe's ground clip. A connector that accepts the probe body without the probe tip would be much better, and as I recall, Tektronix used to sell such connectors.

In my case, I don't have anything suitable, so I used the nickel plated paper clip. Solder flux, in addition to that in the flux core solder, was applied to the paper clip while soldering. I think it helped a lot. 🔗 External reference

More: To make a X10 capacitive attenuator, simply select a variable capacitor, C2 that has an adjustment range that includes the capacitance, that when added to Cin, the input capacitance of the scope probe you are going to use with it, is nine times that of the coupling capacitor. In this circuit, the coupling capacitor, C1, is 2 pF and the scope probe's input capacitance is about 16 pF, so C2 is

C2 = (9X C1) - Cin

C2 = (9 X 2 pF) - 16 pF

C2 = 2 pF

This set of values puts 90% of the voltage across C1 and 10% across C2 and the scope probe. This also works for higher attenuations, but since signals of a few volts or less are typically used, X10 is about as high as needed.

Construction and Calibration

This circuit is constructed on a small piece of pre-punched fiberglass board with a plated metalization pattern. The leads are kept short to minimize stray reactances. A couple of centimeters of bare #30 tinned copper wire serves as the probe. A small hook at the end allows the probe to "hang" on component leads. Occasionally, the tip of the wire is soldered to the circuit under test.

A short length of hookup wire connects the adapter to an alligator clip, which provides the ground contact for the circuit under test. It is advisable to keep this wire as short as possible. For frequencies above 50 MHz, soldering a short piece of wire, approximately 1 cm long, directly from the adapter's ground to the circuit under test is recommended.

Two pieces of nickel-plated paper clip are soldered to the board to serve as connection points for the scope probe and the probe's ground clip. While a connector that accepts the probe body without the probe tip would be ideal, nickel-plated paper clips are used as a substitute in this case. Solder flux, in addition to that in the flux core solder, is applied to the paper clip during soldering to enhance the connection quality.

This design effectively creates a X10 capacitive attenuator, ensuring minimal loading on the circuit under test while maintaining signal integrity at elevated frequencies.The capacitance between the wire and the probe would form a capacitive voltage divider with the probe's input capacitance, and at frequencies significantly higher than the low frequency roll off created by the probe's input capacitance and the probe's resistance, the wave form would be faithfully reproduced, although it would have a reduced amplitude. The circuit give here, presents about a 2 pf load to the circuit, and capacitively loads the circuit measurably less than the X100 voltage probe (A Stack CP-241) I often use for this sort of thing.

To make a X10 capacitive attenuator, simply select a variable capacitor, C2 that has an adjustment range that includes the capacitance, that when added to Cin, the input capacitance of the scope probe you are going to use with it, is nine times that of the coupling capacitor. In this circuit, the coupling capacitor, C1. is 2 pf and the scope probe's input capacitance is about 16 pf, so C2 is C2 = (9X C1) - Cin C2 =( 9 X 2 pf ) -16 pf C= 2pf This set of values puts 90% of the voltage across C1 and 10% across C2 and the scope probe.

This also works for higher attenuations, but since I am working with signals of a few volts or less, X10 is about as high as I need to go. Construction and Calibration I built this on a small piece of pre-punched fiberglass board with a plated metalization pattern.

The leads are all short to minimize stray reactances. A couple cm of bare #30 tinned copper wire serves as the probe. A small hook at the end lets me "hang" the probe on component leads. I also occasionally solder the tip of the wire to the circuit under test. A short length of hookup wire makes the ground connection from the adapter to an alligator clip which makes the ground contact for the circuit under test. The shorter the better. For frequencies above 50 MHz, it would be much better to just solder a short piece of wire, about 1 cm long, from the adapter's ground to the circuit under test.

Two pieces of nickel plated paper clip are soldered to the board to serve as connection points for the scope probe and the probe's ground clip. A connector that accepts the probe body without the probe tip would be much better, and as I recall, Tektronix used to sell such connectors.

In my case, I don't have anything suitable, so I used the nickel plated paper clip. Solder flux, in addition to that in the flux core solder, was applied to the paper clip while soldering. I think it helped a lot. 🔗 External reference