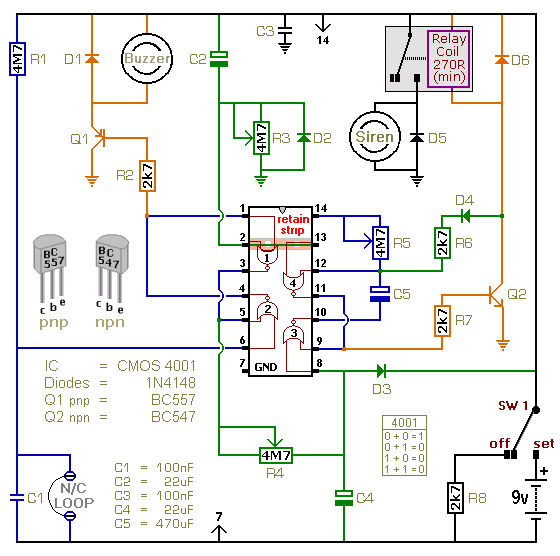

Self-Powered Fast Battery Tester Schematic

This circuit conducts a rapid battery test without requiring an external power supply or costly moving-coil voltmeters. It offers two testing ranges: when switch SW1 is configured as indicated in the circuit diagram, it can evaluate batteries ranging from 3V to 15V. When SW1 is toggled to the alternate position, it is capable of testing only 1.5V cells. Field-effect transistor Q1 functions as a constant current generator for biasing. LED D1 and the base of Q2 are also involved in this process. Consequently, D1 emits light at a consistent intensity, unaffected by the battery voltage within the range of 3V to 15V, while Q2, when switch P1 is engaged, applies a constant current load of approximately 120mA to the battery. Integrated circuit IC1 serves as a square wave generator oscillating at around 3kHz. IC2 operates as an inverter, driving diodes D2 to D6 and capacitors C4 to C7 in an anti-phase manner to achieve voltage multiplication. Capacitor C8 is charged by this elevated voltage, and resistors R8 to R10 form a voltage divider that biases the base of Q3. When P1 is not engaged, a minimal load is applied to the battery under test, keeping LED D7 off by biasing the base of Q3. Activating P1 applies a 120mA load to the battery. If the battery is not fully charged, its output voltage will begin to drop. When this voltage decreases to 0.6V below the nominal voltage, the emitter of Q3 becomes more negative than the base, leading to hard biasing of the transistor and illumination of D7. This condition persists for a brief duration, determined by the time it takes for C8 to decrease its voltage to the new level, which is proportional to the loaded battery voltage. If the battery is adequately charged, its output voltage will not dip below the 120mA load, keeping LED D7 off. For testing 1.5V batteries, the circuit involving Q1, Q2, D1, and resistors R1 and R2 does not function effectively at this supply voltage. Therefore, a load current of 150mA is applied to the battery under test using a 10-ohm resistor R3 after SW1A is switched. The biasing of Q3 is also modified via SW1B.

This circuit design efficiently tests battery performance across a range of voltages, utilizing a combination of transistors, integrated circuits, and passive components to create a reliable testing mechanism. The use of FET Q1 as a constant current source ensures that the testing conditions remain stable regardless of the battery's initial voltage. This is critical for obtaining accurate readings during the test. The square wave generator (IC1) plays a pivotal role in producing a consistent oscillation that drives the inverter (IC2), which in turn controls the voltage multiplication process through the series of diodes and capacitors.

The LED indicators provide visual feedback regarding the battery's condition. LED D1 indicates the operational status of the circuit, while LED D7 serves as a warning indicator for under-voltage conditions. The design intelligently incorporates a voltage divider (R8-R10) to ensure that the biasing of Q3 is responsive to the battery's voltage level, allowing for a nuanced response to different battery states.

For the 1.5V battery testing configuration, the circuit adapts by applying a higher current load through the 10-ohm resistor, which compensates for the lower voltage range and ensures that the testing conditions remain effective. The inclusion of switches SW1A and SW1B allows for user-friendly operation, enabling quick adjustments to the testing parameters without complex reconfiguration.

Overall, this circuit represents a practical solution for battery testing, combining efficiency, cost-effectiveness, and ease of use, making it suitable for a variety of applications in both consumer and industrial settings.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It features two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1. 5V cells can be tested. FET Q1 provides a constant current generator biasing LED D1 and Q2 Base. In this manner D1 illuminates at a constant intensity, independent of battery voltage from 3 to 15V and Q2 (when P1 is closed) applies a constant current load of about 120mA to the battery. IC1 is a square wave generator oscillating at about 3KHz. IC2 acts as an inverter and drives, together with IC1 but in anti-phase, Diodes D2-D6 and Capacitors C4-C7, obtaining a voltage multiplication.

C8 is charged by this raised voltage and R8-R10 form a voltage divider biasing the Base of Q3. When P1 is open, a very light load is applied to the battery under test and Q3 Base is biased in order to maintain LED D7 in the off state. Closing P1, a 120mA load is applied to the battery under test. If the battery is not fully charged, its output voltage starts reducing: when this voltage fall 0. 6V below the battery nominal voltage, Q3 Emitter becomes more negative than the Base, the transistor is hard biased and D7 illuminates.

Obviously, this state of affairs will last a few seconds: the time spent by C8 to reduce its initial voltage to the new one, proportional to the voltage of the loaded battery. If the battery under test is in a good charging state, its output voltage will not fall under a 120mA loading current, so LED D7 will stay off.

When testing 1. 5V batteries, the circuit formed by Q1, Q2, D1, and R1 & R2 does not work well at this supply voltage, so a 150mA load current is applied to the BUT by means of the 10 Ohm resistor R3 after switching SW1A. Q3 bias is also changed via SW1B. 🔗 External reference

This circuit design efficiently tests battery performance across a range of voltages, utilizing a combination of transistors, integrated circuits, and passive components to create a reliable testing mechanism. The use of FET Q1 as a constant current source ensures that the testing conditions remain stable regardless of the battery's initial voltage. This is critical for obtaining accurate readings during the test. The square wave generator (IC1) plays a pivotal role in producing a consistent oscillation that drives the inverter (IC2), which in turn controls the voltage multiplication process through the series of diodes and capacitors.

The LED indicators provide visual feedback regarding the battery's condition. LED D1 indicates the operational status of the circuit, while LED D7 serves as a warning indicator for under-voltage conditions. The design intelligently incorporates a voltage divider (R8-R10) to ensure that the biasing of Q3 is responsive to the battery's voltage level, allowing for a nuanced response to different battery states.

For the 1.5V battery testing configuration, the circuit adapts by applying a higher current load through the 10-ohm resistor, which compensates for the lower voltage range and ensures that the testing conditions remain effective. The inclusion of switches SW1A and SW1B allows for user-friendly operation, enabling quick adjustments to the testing parameters without complex reconfiguration.

Overall, this circuit represents a practical solution for battery testing, combining efficiency, cost-effectiveness, and ease of use, making it suitable for a variety of applications in both consumer and industrial settings.This circuit runs a fast battery test without the need of power supply or expensive moving-coil voltmeters. It features two ranges: when SW1 is set as shown in the circuit diagram, the device can test 3V to 15V batteries.

When SW1 is switched to the other position, only 1. 5V cells can be tested. FET Q1 provides a constant current generator biasing LED D1 and Q2 Base. In this manner D1 illuminates at a constant intensity, independent of battery voltage from 3 to 15V and Q2 (when P1 is closed) applies a constant current load of about 120mA to the battery. IC1 is a square wave generator oscillating at about 3KHz. IC2 acts as an inverter and drives, together with IC1 but in anti-phase, Diodes D2-D6 and Capacitors C4-C7, obtaining a voltage multiplication.

C8 is charged by this raised voltage and R8-R10 form a voltage divider biasing the Base of Q3. When P1 is open, a very light load is applied to the battery under test and Q3 Base is biased in order to maintain LED D7 in the off state. Closing P1, a 120mA load is applied to the battery under test. If the battery is not fully charged, its output voltage starts reducing: when this voltage fall 0. 6V below the battery nominal voltage, Q3 Emitter becomes more negative than the Base, the transistor is hard biased and D7 illuminates.

Obviously, this state of affairs will last a few seconds: the time spent by C8 to reduce its initial voltage to the new one, proportional to the voltage of the loaded battery. If the battery under test is in a good charging state, its output voltage will not fall under a 120mA loading current, so LED D7 will stay off.

When testing 1. 5V batteries, the circuit formed by Q1, Q2, D1, and R1 & R2 does not work well at this supply voltage, so a 150mA load current is applied to the BUT by means of the 10 Ohm resistor R3 after switching SW1A. Q3 bias is also changed via SW1B. 🔗 External reference