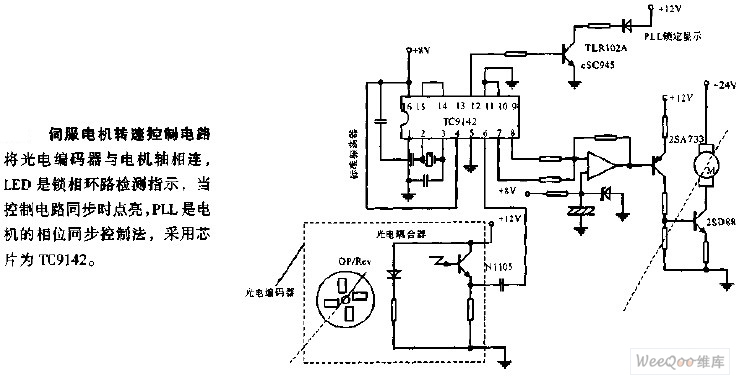

Servo motor speed control circuit

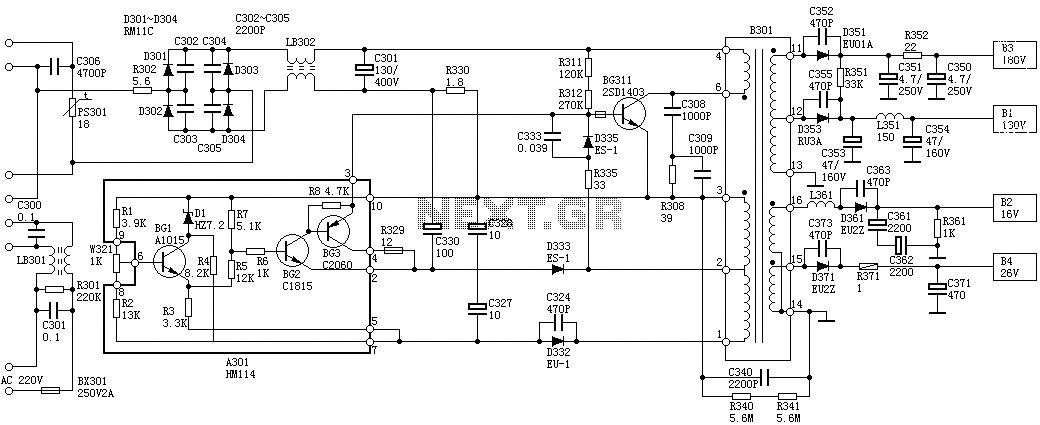

The servo motor speed control circuit connects the photoelectric encoder to the motor shaft. The LED serves as an indicator light for the phase-locked loop (PLL) detection, illuminating when the control circuit is synchronized. The PLL employs a phase synchronous control method for the electric motor, utilizing the TC9142 chip.

The servo motor speed control circuit is designed to regulate the speed of a servo motor by implementing a feedback mechanism that utilizes a photoelectric encoder. This encoder is mechanically linked to the motor shaft, providing real-time position and speed data to the control system. The integration of the encoder allows for precise control of motor speed, ensuring that the motor operates at the desired setpoint.

The phase-locked loop (PLL) is a critical component of this circuit, serving to synchronize the motor's operation with the input signal. The TC9142 chip is utilized for its capabilities in phase detection and control. This chip processes the feedback from the encoder, comparing the actual motor speed to the desired speed. If a discrepancy is detected, the PLL adjusts the control signals sent to the motor, thereby achieving synchronization.

The LED indicator plays an essential role in providing visual feedback regarding the status of the PLL. When the control circuit achieves synchronization, the LED illuminates, signaling that the motor is operating correctly within its designated parameters. Conversely, if the LED is off, it may indicate a loss of synchronization, prompting further investigation into the system's performance.

In summary, this servo motor speed control circuit combines the functionalities of a photoelectric encoder, a PLL for phase synchronization, and an LED indicator to create an efficient and effective motor control solution. The use of the TC9142 chip enhances the circuit's ability to maintain precise control over motor speed and performance, making it suitable for various applications in automation and robotics.The servo motor speed control circuit connects the photoelectric encoder with the motor shaft, the LED is the indicator light of the PLL detection, it turns on when the control circuit is synchronous. The PLL is the phase synchronous control method of the electrical moter, it uses the chip of TC9142..

🔗 External reference

The servo motor speed control circuit is designed to regulate the speed of a servo motor by implementing a feedback mechanism that utilizes a photoelectric encoder. This encoder is mechanically linked to the motor shaft, providing real-time position and speed data to the control system. The integration of the encoder allows for precise control of motor speed, ensuring that the motor operates at the desired setpoint.

The phase-locked loop (PLL) is a critical component of this circuit, serving to synchronize the motor's operation with the input signal. The TC9142 chip is utilized for its capabilities in phase detection and control. This chip processes the feedback from the encoder, comparing the actual motor speed to the desired speed. If a discrepancy is detected, the PLL adjusts the control signals sent to the motor, thereby achieving synchronization.

The LED indicator plays an essential role in providing visual feedback regarding the status of the PLL. When the control circuit achieves synchronization, the LED illuminates, signaling that the motor is operating correctly within its designated parameters. Conversely, if the LED is off, it may indicate a loss of synchronization, prompting further investigation into the system's performance.

In summary, this servo motor speed control circuit combines the functionalities of a photoelectric encoder, a PLL for phase synchronization, and an LED indicator to create an efficient and effective motor control solution. The use of the TC9142 chip enhances the circuit's ability to maintain precise control over motor speed and performance, making it suitable for various applications in automation and robotics.The servo motor speed control circuit connects the photoelectric encoder with the motor shaft, the LED is the indicator light of the PLL detection, it turns on when the control circuit is synchronous. The PLL is the phase synchronous control method of the electrical moter, it uses the chip of TC9142..

🔗 External reference