Simple analogue Tachometer

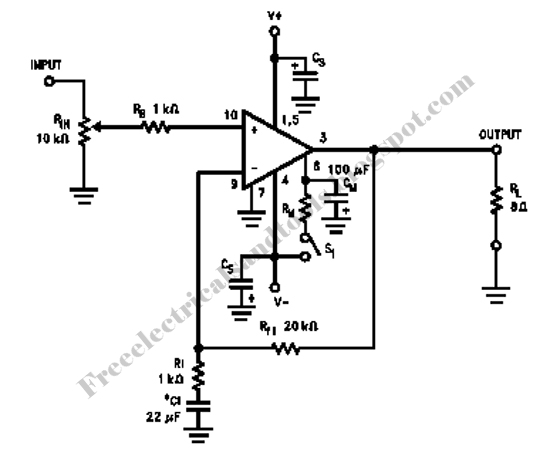

Basically, this is a frequency-current converter. It is used as a frequency meter. Calibrating it can be used as a tachometer. Please be aware this is an experimental project; it wasn't connected to any vehicle, but it should work fine after calibration. It can be connected directly to the voltage from the car. The input signal can be connected directly to any source of frequency. It is believed that it will work fine if it is connected directly to the spark plug line. Be sure not to use germanium diodes for this one. Any silicon diode should work fine. The diodes at the input reduce the voltage to a safe level (0.7 Volts). DO NOT CONNECT the circuit without doing the calibration first. The bridge diode that is connected to the milliammeter can be replaced by four silicon diodes as the picture shows. The milliammeter can be replaced by a multimeter set to measure mA. To calibrate this circuit first: Adjust R1 and R2 at the middle point. Apply power (12 Volts) and apply 60Hz at the input signal. Adjust R1 until it measures 0.360 (3,600 RPM). Stop the signal (0 Hz) and adjust R3 until the meter indicates 0. Apply 60Hz again and adjust R1. If the meter doesn't show "0" at 0 Hz and 0.36 at 60Hz, adjust R2 and repeat the calibration.

The circuit described is a frequency-current converter designed for use as a frequency meter and can also function as a tachometer upon proper calibration. The primary components include a power supply of 12 Volts, silicon diodes, resistors (R1, R2, R3), and a measuring device, such as a milliammeter or a multimeter set to measure milliamperes.

The operational principle involves converting an input frequency signal into a corresponding current output. The input can be sourced from various frequency-generating devices, including direct connections to the spark plug line of an engine. The use of silicon diodes is crucial, as they ensure that the voltage is clamped to a safe level of approximately 0.7 Volts, protecting the circuit from overvoltage conditions.

Calibration is essential for accurate operation. The initial step involves adjusting resistors R1 and R2 to their midpoint settings. Following this, a stable 60Hz signal is introduced to the input while monitoring the output on the measuring device. The adjustment of R1 is then carried out until the device reads 0.360, which corresponds to a rotational speed of 3,600 RPM. After this adjustment, the frequency signal should be removed, and R3 should be adjusted to bring the meter reading back to zero. The calibration process is iterative; if the device does not read zero at 0 Hz or 0.36 at 60Hz, further adjustments to R2 are necessary, followed by a repeat of the calibration steps.

The bridge diode configuration can be replaced by four silicon diodes arranged appropriately to maintain the functionality of the circuit while allowing for easy replacement and adjustments. This circuit is suitable for experimental applications and should be handled with care, particularly during the calibration phase to ensure accurate readings and prevent damage to the components.Basically, this is a frequency-current converter. It is used as frequency meter. Calibrating it can be used as tachometer. Please be aware this is an experimental project, I didn't use it connected on any vehicle but it should work fine after calibration. It can be connected directly to the voltage from the car. The input signal can be connected directly to any source of frequency. I believe it will work fine if it is connected directly to the spark plug line. Be sure not to use germanium diodes for this one. Any silicon diode should work fine. The diodes at the input reduces the voltage to a safe level ( 0.7 Volts). DO NOT CONNECT the circuit without doing the calibration first.

The circuit described is a frequency-current converter designed for use as a frequency meter and can also function as a tachometer upon proper calibration. The primary components include a power supply of 12 Volts, silicon diodes, resistors (R1, R2, R3), and a measuring device, such as a milliammeter or a multimeter set to measure milliamperes.

The operational principle involves converting an input frequency signal into a corresponding current output. The input can be sourced from various frequency-generating devices, including direct connections to the spark plug line of an engine. The use of silicon diodes is crucial, as they ensure that the voltage is clamped to a safe level of approximately 0.7 Volts, protecting the circuit from overvoltage conditions.

Calibration is essential for accurate operation. The initial step involves adjusting resistors R1 and R2 to their midpoint settings. Following this, a stable 60Hz signal is introduced to the input while monitoring the output on the measuring device. The adjustment of R1 is then carried out until the device reads 0.360, which corresponds to a rotational speed of 3,600 RPM. After this adjustment, the frequency signal should be removed, and R3 should be adjusted to bring the meter reading back to zero. The calibration process is iterative; if the device does not read zero at 0 Hz or 0.36 at 60Hz, further adjustments to R2 are necessary, followed by a repeat of the calibration steps.

The bridge diode configuration can be replaced by four silicon diodes arranged appropriately to maintain the functionality of the circuit while allowing for easy replacement and adjustments. This circuit is suitable for experimental applications and should be handled with care, particularly during the calibration phase to ensure accurate readings and prevent damage to the components.Basically, this is a frequency-current converter. It is used as frequency meter. Calibrating it can be used as tachometer. Please be aware this is an experimental project, I didn't use it connected on any vehicle but it should work fine after calibration. It can be connected directly to the voltage from the car. The input signal can be connected directly to any source of frequency. I believe it will work fine if it is connected directly to the spark plug line. Be sure not to use germanium diodes for this one. Any silicon diode should work fine. The diodes at the input reduces the voltage to a safe level ( 0.7 Volts). DO NOT CONNECT the circuit without doing the calibration first.

The bridge diode that is connected to the miliamperimeter can be replaced by 4 silicon diodes as the picture shows. The miliamperimeter can be replaced by a multi-meter set to measure mA. To calibrate this circuit first: Adjust R1 and R2 at the middle point. Apply power (12 Volts) and apply 60Hz at the input signal. Adjust R1 until it measures 0.360 (3,600 RPM) Stop the signal (0 hz) and adjust R3 until the meter indicates 0.

Apply 60Hz again and adjust R1. If the meter doesn't show "0" at 0Hz and 0.36 at 60Hz, adjust R2 and repeat the calibration.