Simple Stepper Motor Controller

A stepper motor controller is required to operate a stepper motor, as a stepper motor cannot function merely by connecting it to a power supply.

A stepper motor controller is an essential component for the effective operation of stepper motors, which are widely used in various applications requiring precise control of position, speed, and torque. Unlike standard DC motors, stepper motors require specific control signals that dictate their movement in discrete steps. This characteristic enables them to achieve high precision in positioning without the need for feedback systems.

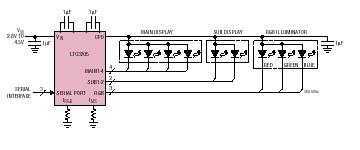

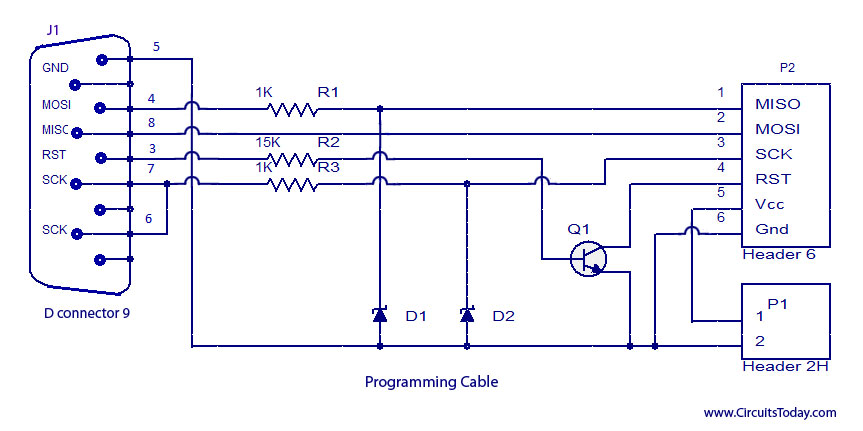

The controller typically interfaces with a microcontroller or a computer to receive commands regarding the desired movement. It converts these commands into a series of electrical pulses that are sent to the stepper motor. Each pulse corresponds to a specific step of the motor, allowing for controlled rotation in either direction. The controller can also manage the speed of the motor by adjusting the frequency of the pulses.

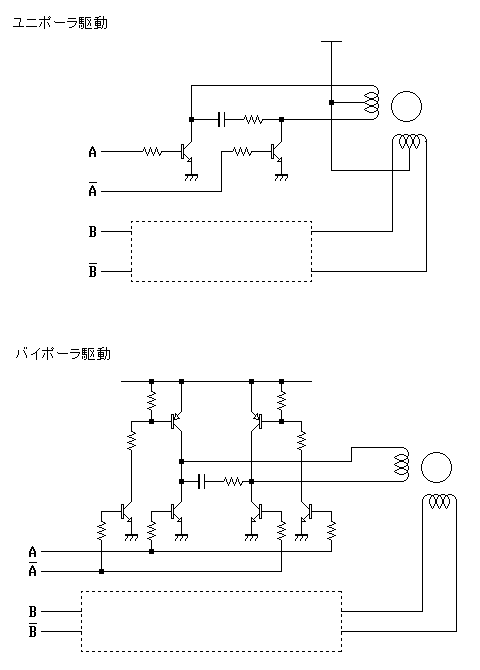

There are various types of stepper motor controllers, including unipolar and bipolar configurations, each designed to drive different types of stepper motors. Unipolar controllers often simplify the control mechanism by allowing current to flow in one direction through the motor coils, while bipolar controllers provide greater torque and efficiency by enabling current to flow in both directions.

In addition to basic functionality, advanced stepper motor controllers may include features such as microstepping, which allows for smoother motion and finer resolution by dividing each full step into smaller increments. This is particularly useful in applications requiring high precision, such as CNC machines or 3D printers.

Overall, a stepper motor controller is crucial for harnessing the full capabilities of stepper motors, enabling applications that demand accurate and reliable motion control.Stepper motor controller is needed to run a stepper motor, since a stepper motor cannot work by just connecting it to a power supply. ?To program a stepper. 🔗 External reference

A stepper motor controller is an essential component for the effective operation of stepper motors, which are widely used in various applications requiring precise control of position, speed, and torque. Unlike standard DC motors, stepper motors require specific control signals that dictate their movement in discrete steps. This characteristic enables them to achieve high precision in positioning without the need for feedback systems.

The controller typically interfaces with a microcontroller or a computer to receive commands regarding the desired movement. It converts these commands into a series of electrical pulses that are sent to the stepper motor. Each pulse corresponds to a specific step of the motor, allowing for controlled rotation in either direction. The controller can also manage the speed of the motor by adjusting the frequency of the pulses.

There are various types of stepper motor controllers, including unipolar and bipolar configurations, each designed to drive different types of stepper motors. Unipolar controllers often simplify the control mechanism by allowing current to flow in one direction through the motor coils, while bipolar controllers provide greater torque and efficiency by enabling current to flow in both directions.

In addition to basic functionality, advanced stepper motor controllers may include features such as microstepping, which allows for smoother motion and finer resolution by dividing each full step into smaller increments. This is particularly useful in applications requiring high precision, such as CNC machines or 3D printers.

Overall, a stepper motor controller is crucial for harnessing the full capabilities of stepper motors, enabling applications that demand accurate and reliable motion control.Stepper motor controller is needed to run a stepper motor, since a stepper motor cannot work by just connecting it to a power supply. ?To program a stepper. 🔗 External reference