Single Button Force Sensing Resistor

The FlexiForce sensor functions as a force-sensing resistor within an electrical circuit. When the sensor is not under load, its resistance is significantly high. Upon the application of force, this resistance decreases. The resistance can be measured by connecting a multimeter to the outer two pins of the sensor and applying force to the sensing area. The relationship between force and resistance, as well as force and conductance (1/R), is illustrated in accompanying figures. The conductance curve is linear, making it beneficial for calibration purposes. One method to integrate the FlexiForce sensor into an application is by utilizing it in a force-to-voltage circuit, necessitating a calibration process to convert the output into appropriate engineering units. Adjustments can be made to enhance or reduce the sensitivity of the force sensor based on the specific setup. A typical sensor response is demonstrated in a recommended drive circuit. Additionally, a complete force measurement system, known as the ELF System, is available, which includes force measurement software, electronics, and the sensors themselves. The FlexiForce force sensor is an ultra-thin, flexible printed circuit. The standard A201 force sensor comprises two layers of polyester film, while the high-temperature model (HT201) is made of two layers of polyimide. The active sensing area is marked by a silver circle on top of pressure-sensitive ink, with silver extending from this area to the connectors, forming conductive leads. The A201 sensors feature male square pins for easy integration into a circuit, with the two outer pins being active and the center pin being inactive. FlexiForce Sensors are capable of measuring force between nearly any two mating surfaces, with various applications demonstrated by recent customer implementations.

The FlexiForce sensor is designed to provide precise force measurements in a variety of applications, leveraging its unique resistance properties. The sensor operates on the principle of varying resistance in response to applied force, making it suitable for integration into custom electronic circuits. The calibration process is essential for converting the sensor's output into meaningful engineering units, allowing for accurate force measurement in applications such as robotics, automotive testing, and industrial automation.

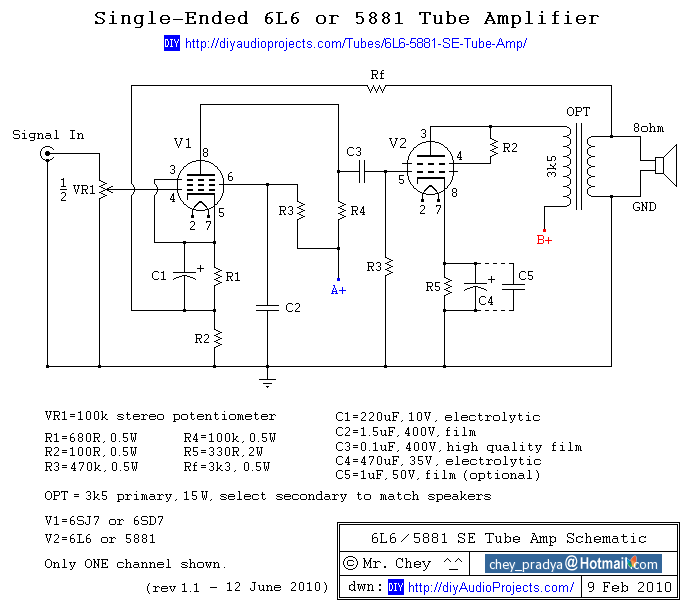

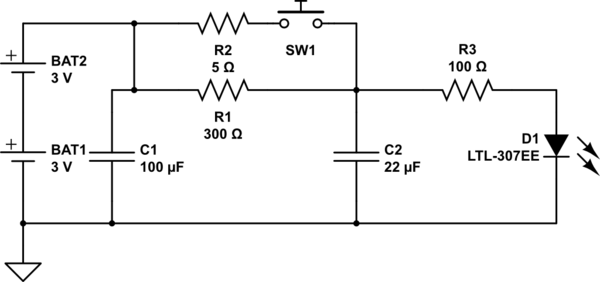

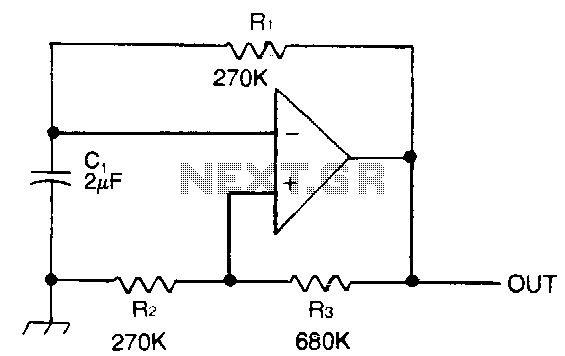

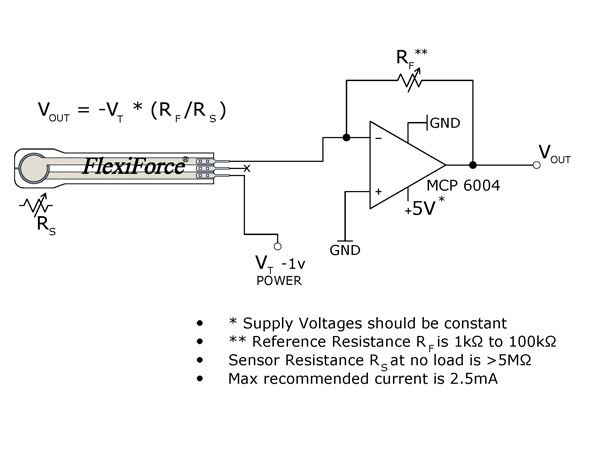

In a typical force-to-voltage circuit, the FlexiForce sensor can be paired with operational amplifiers to convert the variable resistance into a voltage output. This configuration often includes a resistor in series with the sensor to form a voltage divider, enabling the measurement of the voltage drop across the sensor as it experiences varying force levels. The output voltage can then be further processed by analog-to-digital converters (ADCs) for digital interfacing with microcontrollers or other processing units.

The construction of the FlexiForce sensors, particularly the A201 and HT201 models, enhances their versatility and durability. The use of flexible printed circuits allows for integration into spaces where traditional sensors may not fit, while the choice of materials ensures performance under various environmental conditions. The male square pins facilitate easy connection to breadboards or custom PCBs, promoting rapid prototyping and development.

Furthermore, the ELF System provides a comprehensive solution for users seeking a complete force measurement setup. This system not only includes the necessary hardware but also the software for data acquisition and analysis, making it suitable for researchers and engineers looking to implement force measurement in their projects without extensive setup time.

Overall, the FlexiForce sensor represents a flexible and effective solution for measuring force in a wide range of applications, offering both ease of integration and reliable performance.The FlexiForce sensor acts as a force sensing resistor in an electrical circuit. When the force sensor is unloaded, its resistance is very high. When a force is applied to the sensor, this resistance decreases. The resistance can be read by connecting a multimeter to the outer two pins, then applying a force to the sensing area. Figure 1 below sho ws both the Force vs. Resistance and Force vs. Conductance (1/R). Note that the conductance curve is linear, and therefore useful in calibration. One way to integrate the FlexiForce sensor into an application is to incorporate it into a force-to-voltage circuit. A means of calibration must then be established to convert the output into the appropriate engineering units.

Depending on the setup, an adjustment could then be done to increase or decrease the sensitivity of the force sensor. Figure 2 below shows a typical sensor response (based on our recommended drive circuit ). We also offer a complete force measurement system. The ELF System is a turnkey package containing force measurement software, electronics, and force sensors.

The FlexiForce force sensor is an ultra-thin, flexible printed circuit. The standard A201 force sensor is constructed of two layers of substrate (polyester) film. The high-temp model (HT201) is constructed of two layers of polyimide. The active sensing area is defined by the silver circle on top of the pressure-sensitive ink. Silver extends from the sensing area to the connectors at the other end of the sensor, forming the conductive leads. A201 sensors are terminated with male square pins, allowing them to be easily incorporated into a circuit.

The two outer pins of the connector are active and the center pin is inactive. FlexiForce Sensors measure force between virtually any two mating surfaces. Below are a few recent examples demonstrating ways customers are using our technology. 🔗 External reference

The FlexiForce sensor is designed to provide precise force measurements in a variety of applications, leveraging its unique resistance properties. The sensor operates on the principle of varying resistance in response to applied force, making it suitable for integration into custom electronic circuits. The calibration process is essential for converting the sensor's output into meaningful engineering units, allowing for accurate force measurement in applications such as robotics, automotive testing, and industrial automation.

In a typical force-to-voltage circuit, the FlexiForce sensor can be paired with operational amplifiers to convert the variable resistance into a voltage output. This configuration often includes a resistor in series with the sensor to form a voltage divider, enabling the measurement of the voltage drop across the sensor as it experiences varying force levels. The output voltage can then be further processed by analog-to-digital converters (ADCs) for digital interfacing with microcontrollers or other processing units.

The construction of the FlexiForce sensors, particularly the A201 and HT201 models, enhances their versatility and durability. The use of flexible printed circuits allows for integration into spaces where traditional sensors may not fit, while the choice of materials ensures performance under various environmental conditions. The male square pins facilitate easy connection to breadboards or custom PCBs, promoting rapid prototyping and development.

Furthermore, the ELF System provides a comprehensive solution for users seeking a complete force measurement setup. This system not only includes the necessary hardware but also the software for data acquisition and analysis, making it suitable for researchers and engineers looking to implement force measurement in their projects without extensive setup time.

Overall, the FlexiForce sensor represents a flexible and effective solution for measuring force in a wide range of applications, offering both ease of integration and reliable performance.The FlexiForce sensor acts as a force sensing resistor in an electrical circuit. When the force sensor is unloaded, its resistance is very high. When a force is applied to the sensor, this resistance decreases. The resistance can be read by connecting a multimeter to the outer two pins, then applying a force to the sensing area. Figure 1 below sho ws both the Force vs. Resistance and Force vs. Conductance (1/R). Note that the conductance curve is linear, and therefore useful in calibration. One way to integrate the FlexiForce sensor into an application is to incorporate it into a force-to-voltage circuit. A means of calibration must then be established to convert the output into the appropriate engineering units.

Depending on the setup, an adjustment could then be done to increase or decrease the sensitivity of the force sensor. Figure 2 below shows a typical sensor response (based on our recommended drive circuit ). We also offer a complete force measurement system. The ELF System is a turnkey package containing force measurement software, electronics, and force sensors.

The FlexiForce force sensor is an ultra-thin, flexible printed circuit. The standard A201 force sensor is constructed of two layers of substrate (polyester) film. The high-temp model (HT201) is constructed of two layers of polyimide. The active sensing area is defined by the silver circle on top of the pressure-sensitive ink. Silver extends from the sensing area to the connectors at the other end of the sensor, forming the conductive leads. A201 sensors are terminated with male square pins, allowing them to be easily incorporated into a circuit.

The two outer pins of the connector are active and the center pin is inactive. FlexiForce Sensors measure force between virtually any two mating surfaces. Below are a few recent examples demonstrating ways customers are using our technology. 🔗 External reference