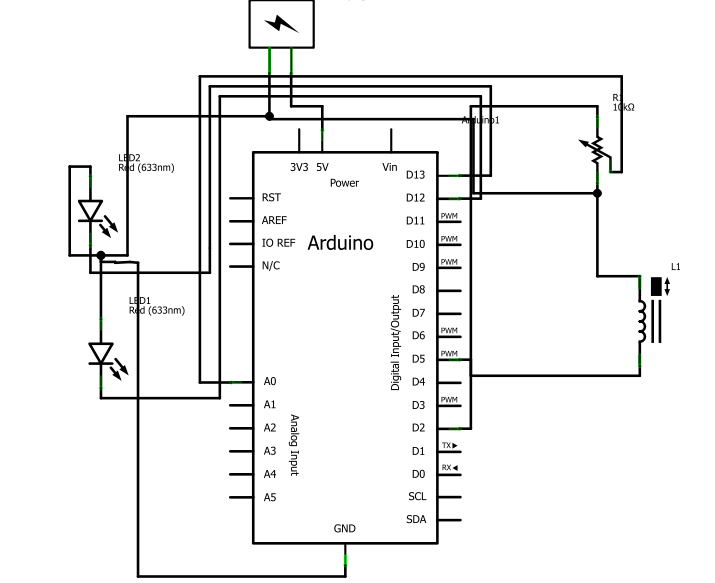

Small Engine ECU EFI Moped Using Ardrino UNO

After several days of considering electronic fuel injection for a moped, a decision has been made to proceed with the project. The required parts have been identified, and the remaining task involves programming.

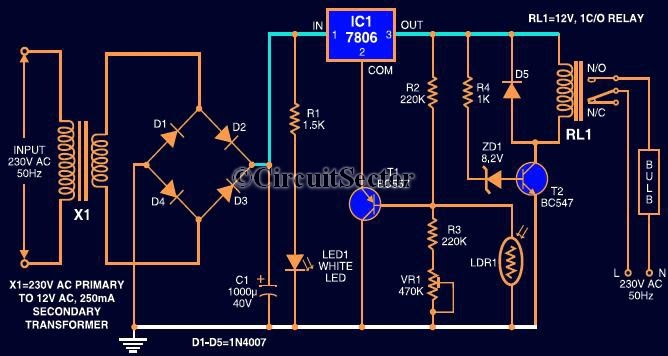

The implementation of electronic fuel injection (EFI) in a moped involves several key components and considerations to ensure optimal performance and efficiency. The primary components of an EFI system include the fuel injector, electronic control unit (ECU), fuel pump, throttle position sensor, manifold absolute pressure (MAP) sensor, and various wiring and connectors.

The fuel injector is responsible for delivering the precise amount of fuel into the engine's intake manifold at the correct timing. This component is typically controlled by the ECU, which calculates the required fuel delivery based on input from various sensors. The ECU processes data from the throttle position sensor, which monitors the position of the throttle valve, and the MAP sensor, which measures the pressure inside the intake manifold. These inputs allow the ECU to determine the optimal air-fuel mixture for combustion.

The fuel pump is essential for maintaining the necessary fuel pressure within the system, ensuring that the fuel injector receives fuel consistently and at the correct pressure. The pump is usually located in the fuel tank and operates based on signals from the ECU, which may also incorporate a fuel pressure regulator to maintain steady pressure.

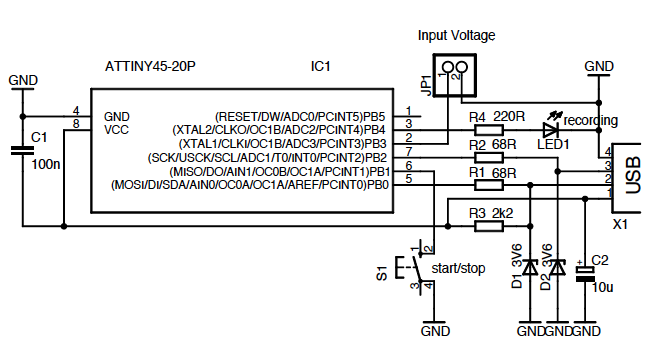

Wiring and connectors are crucial for establishing reliable communication between the ECU and various sensors and components. Proper insulation and routing of wires help to prevent electrical interference and ensure the longevity of the system.

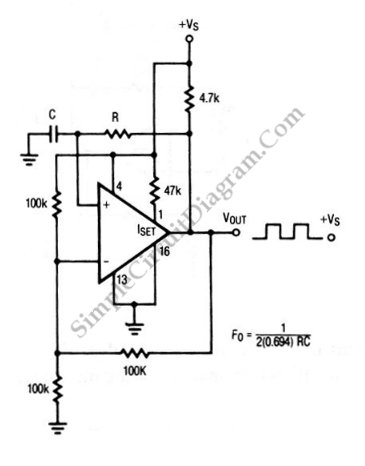

Programming the ECU involves developing a control algorithm that can adapt to various operating conditions, such as temperature, altitude, and engine load. This process may include creating a fuel map that defines the fuel delivery characteristics at different throttle positions and engine speeds.

In conclusion, the integration of electronic fuel injection into a moped enhances its performance and fuel efficiency by providing precise control over the air-fuel mixture. The successful implementation of this system requires careful selection of components, thorough programming, and meticulous attention to detail in the wiring and connections.After some days of thinking about electronic fuel injection for a moped, ive decided to take it on. Parts come up to , and the rest is programming. . 🔗 External reference

The implementation of electronic fuel injection (EFI) in a moped involves several key components and considerations to ensure optimal performance and efficiency. The primary components of an EFI system include the fuel injector, electronic control unit (ECU), fuel pump, throttle position sensor, manifold absolute pressure (MAP) sensor, and various wiring and connectors.

The fuel injector is responsible for delivering the precise amount of fuel into the engine's intake manifold at the correct timing. This component is typically controlled by the ECU, which calculates the required fuel delivery based on input from various sensors. The ECU processes data from the throttle position sensor, which monitors the position of the throttle valve, and the MAP sensor, which measures the pressure inside the intake manifold. These inputs allow the ECU to determine the optimal air-fuel mixture for combustion.

The fuel pump is essential for maintaining the necessary fuel pressure within the system, ensuring that the fuel injector receives fuel consistently and at the correct pressure. The pump is usually located in the fuel tank and operates based on signals from the ECU, which may also incorporate a fuel pressure regulator to maintain steady pressure.

Wiring and connectors are crucial for establishing reliable communication between the ECU and various sensors and components. Proper insulation and routing of wires help to prevent electrical interference and ensure the longevity of the system.

Programming the ECU involves developing a control algorithm that can adapt to various operating conditions, such as temperature, altitude, and engine load. This process may include creating a fuel map that defines the fuel delivery characteristics at different throttle positions and engine speeds.

In conclusion, the integration of electronic fuel injection into a moped enhances its performance and fuel efficiency by providing precise control over the air-fuel mixture. The successful implementation of this system requires careful selection of components, thorough programming, and meticulous attention to detail in the wiring and connections.After some days of thinking about electronic fuel injection for a moped, ive decided to take it on. Parts come up to , and the rest is programming. . 🔗 External reference