Space Horticulture Circuit

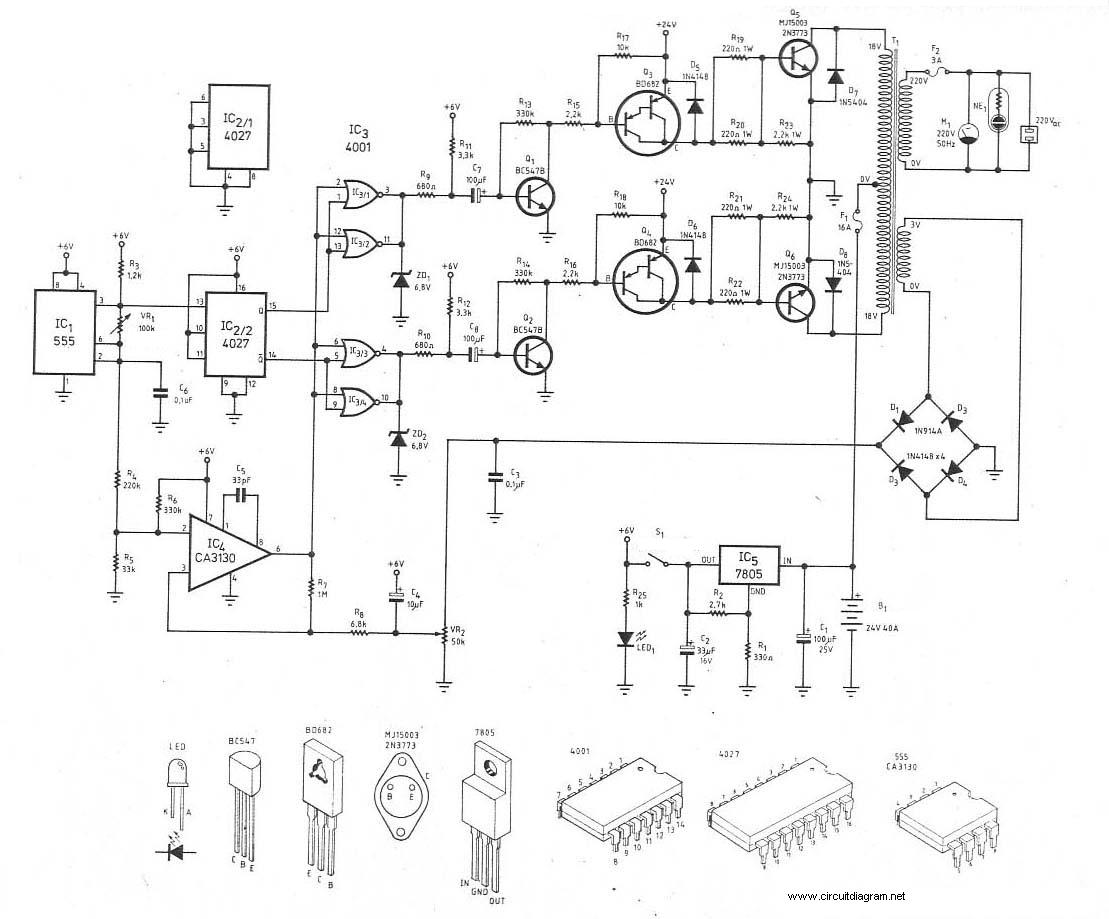

The optimal duty cycle and frequency for the strobe photoperiod need to be established. The circuit designed operates at 3Hz with a 50% duty cycle, selected based on the use of a 1µF capacitor with a 555 timer IC. The output from the 555 timer (pin 3) is connected to the base of an NPN Darlington Transistor (TIP120) designated as T1. This NPN transistor controls the current to the strobe LED lighting module by switching it on and off. A voltage drop occurs across the collector-emitter junction of the TIP120 transistor. To ensure uniform brightness across both LED modules, a dummy TIP120 transistor, T2, is included in series with the control LED module. This configuration allows T2 to match the voltage drop across T1, thereby providing consistent voltage to the control LED modules. The T2 transistor remains in a forward-biased state (always on) when powered through a resistor R4 (2.2 kΩ). The measured voltage drop across the TIP120 transistors is approximately 1.5 volts. The circuit is powered by a 12 VDC wall transformer, which is connected to an inexpensive Radio-Shack AC appliance timer set for a 12-hour operational period. The wall transformer supplies voltage to both circuits.

The proposed circuit operates effectively within the specified parameters, utilizing a 555 timer IC configured in astable mode to generate a square wave signal at 3Hz frequency with a 50% duty cycle. The duty cycle indicates that the LED will be on for half of each cycle, ensuring a balanced illumination effect during operation. The choice of a 1µF capacitor is critical in determining the timing intervals, as it directly influences the charge and discharge rates within the 555 timer circuit.

The TIP120 transistors serve as the primary switching elements in this design. The first TIP120 (T1) is responsible for modulating the power delivered to the strobe LED lighting module, effectively turning it on and off in response to the output from the 555 timer. The second TIP120 (T2) acts as a compensatory element, addressing the voltage drop experienced by T1. By maintaining the voltage drop across T1, T2 ensures that the control LED modules receive a consistent voltage level, thereby achieving uniform brightness across all LEDs.

In this configuration, resistor R4 plays a vital role by providing a forward bias to T2, keeping it continuously in the 'on' state when power is supplied. This arrangement ensures that the control LED modules operate effectively without experiencing fluctuations in brightness caused by variations in the voltage drop across T1.

The power supply for the entire circuit is a 12 VDC wall transformer, which is a common and practical solution for such applications. The integration of an AC appliance timer allows for automation of the lighting system, enabling it to operate for a predetermined duration (12 hours in this case), which is particularly useful for applications requiring periodic illumination.

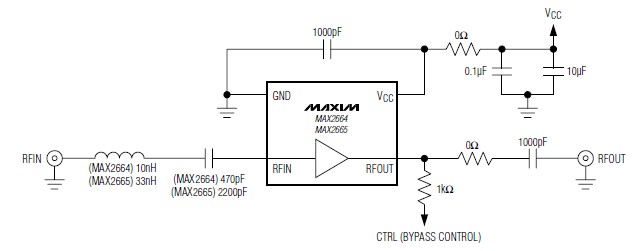

Overall, the design effectively combines timing, switching, and power management to achieve the desired strobe effect while ensuring consistent performance across the LED modules. The schematic representation of the circuit, including the arrangement of components and connections, is essential for visualizing the operational flow and verifying the integrity of the design.The optimum duty cycle and frequency for the strobe photoperiod needs to be determined. In other words we`re flying blind in regard to optimum frequency and duty cycle. The circuit I designed is 3Hz with a 50% duty cycle. I chose this frequency based upon using a convenient 1-uF capacitor, for a 555 timer IC. The schematic is shown in figure 2 (be low). The output from the 555 timer (pin 3) is connected to the base of NPN Darlington Transistor (TIP120) T1. The NPN transistor switches the current on and off to the strobe LED lighting module. There is a voltage drop across the collector-emmiter of the TIP 120 transistor. To insure the equal brightness from both the LED modules, I place a dummy TIP120 transistor, T2, in line with the control LED module (see figure 3, below).

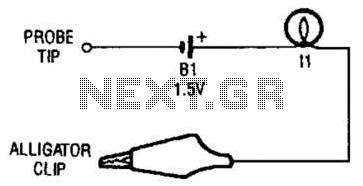

The transistor T2 matches the voltage drop across T1 to help supply an equal voltage to the control LED modules. The T2 transistor is kept forward bias (always on), when power is applied through resistor R4 (2. 2K ohm). The voltage drop I measured across the TIP120 transistors is approximately 1. 5 volts. An overall view is shown in figure 4 (above). A 12 VDC wall transformer powers the circuit. The wall transformer is plugged into an inexpensive Radio-Shack AC appliance timer set for a 12 hour on period.

The wall transformer supplies voltage to both circuits. 🔗 External reference

The proposed circuit operates effectively within the specified parameters, utilizing a 555 timer IC configured in astable mode to generate a square wave signal at 3Hz frequency with a 50% duty cycle. The duty cycle indicates that the LED will be on for half of each cycle, ensuring a balanced illumination effect during operation. The choice of a 1µF capacitor is critical in determining the timing intervals, as it directly influences the charge and discharge rates within the 555 timer circuit.

The TIP120 transistors serve as the primary switching elements in this design. The first TIP120 (T1) is responsible for modulating the power delivered to the strobe LED lighting module, effectively turning it on and off in response to the output from the 555 timer. The second TIP120 (T2) acts as a compensatory element, addressing the voltage drop experienced by T1. By maintaining the voltage drop across T1, T2 ensures that the control LED modules receive a consistent voltage level, thereby achieving uniform brightness across all LEDs.

In this configuration, resistor R4 plays a vital role by providing a forward bias to T2, keeping it continuously in the 'on' state when power is supplied. This arrangement ensures that the control LED modules operate effectively without experiencing fluctuations in brightness caused by variations in the voltage drop across T1.

The power supply for the entire circuit is a 12 VDC wall transformer, which is a common and practical solution for such applications. The integration of an AC appliance timer allows for automation of the lighting system, enabling it to operate for a predetermined duration (12 hours in this case), which is particularly useful for applications requiring periodic illumination.

Overall, the design effectively combines timing, switching, and power management to achieve the desired strobe effect while ensuring consistent performance across the LED modules. The schematic representation of the circuit, including the arrangement of components and connections, is essential for visualizing the operational flow and verifying the integrity of the design.The optimum duty cycle and frequency for the strobe photoperiod needs to be determined. In other words we`re flying blind in regard to optimum frequency and duty cycle. The circuit I designed is 3Hz with a 50% duty cycle. I chose this frequency based upon using a convenient 1-uF capacitor, for a 555 timer IC. The schematic is shown in figure 2 (be low). The output from the 555 timer (pin 3) is connected to the base of NPN Darlington Transistor (TIP120) T1. The NPN transistor switches the current on and off to the strobe LED lighting module. There is a voltage drop across the collector-emmiter of the TIP 120 transistor. To insure the equal brightness from both the LED modules, I place a dummy TIP120 transistor, T2, in line with the control LED module (see figure 3, below).

The transistor T2 matches the voltage drop across T1 to help supply an equal voltage to the control LED modules. The T2 transistor is kept forward bias (always on), when power is applied through resistor R4 (2. 2K ohm). The voltage drop I measured across the TIP120 transistors is approximately 1. 5 volts. An overall view is shown in figure 4 (above). A 12 VDC wall transformer powers the circuit. The wall transformer is plugged into an inexpensive Radio-Shack AC appliance timer set for a 12 hour on period.

The wall transformer supplies voltage to both circuits. 🔗 External reference