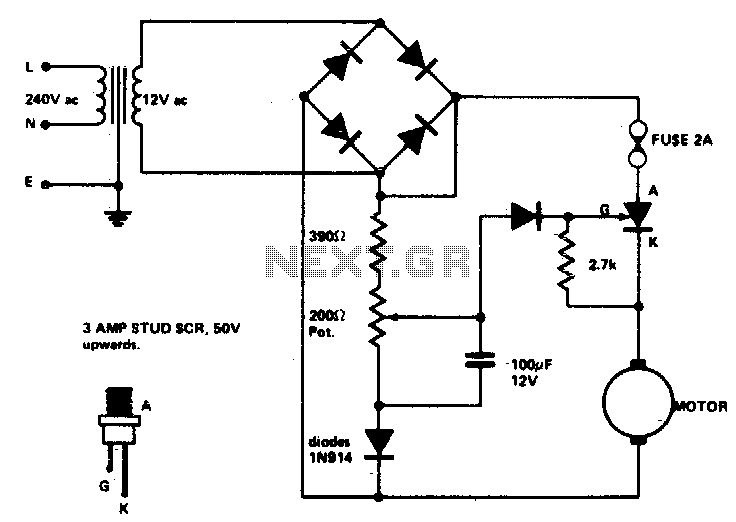

Speed control for model trains or cars

Low voltage speed control provides excellent starting torque and effective speed regulation. Additionally, a reversing switch can be integrated into the motor leads.

Low voltage speed control circuits are essential in applications where precise motor control is required, such as in robotics, conveyor systems, and electric vehicles. The effective starting torque is crucial for applications that involve heavy loads or require immediate acceleration. This can be achieved through pulse-width modulation (PWM) techniques, which allow for the adjustment of the voltage applied to the motor, thus controlling its speed while maintaining high torque levels.

The integration of a reversing switch further enhances the functionality of the motor control system. This switch can be configured to reverse the polarity of the voltage supplied to the motor, enabling bidirectional operation. This is particularly beneficial in applications where the motor must change direction frequently, such as in automated material handling or in devices that require back-and-forth motion.

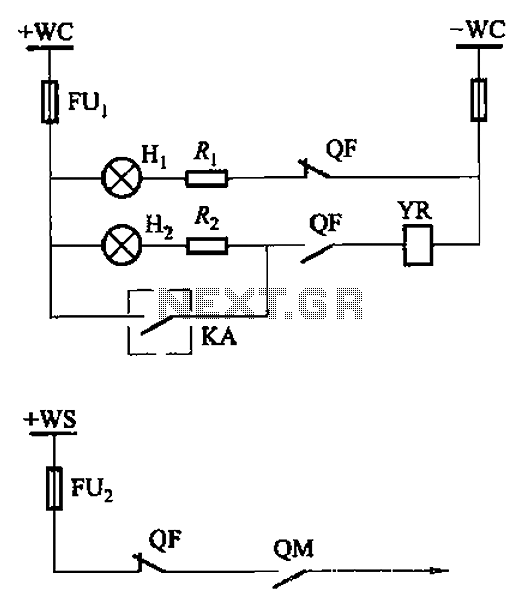

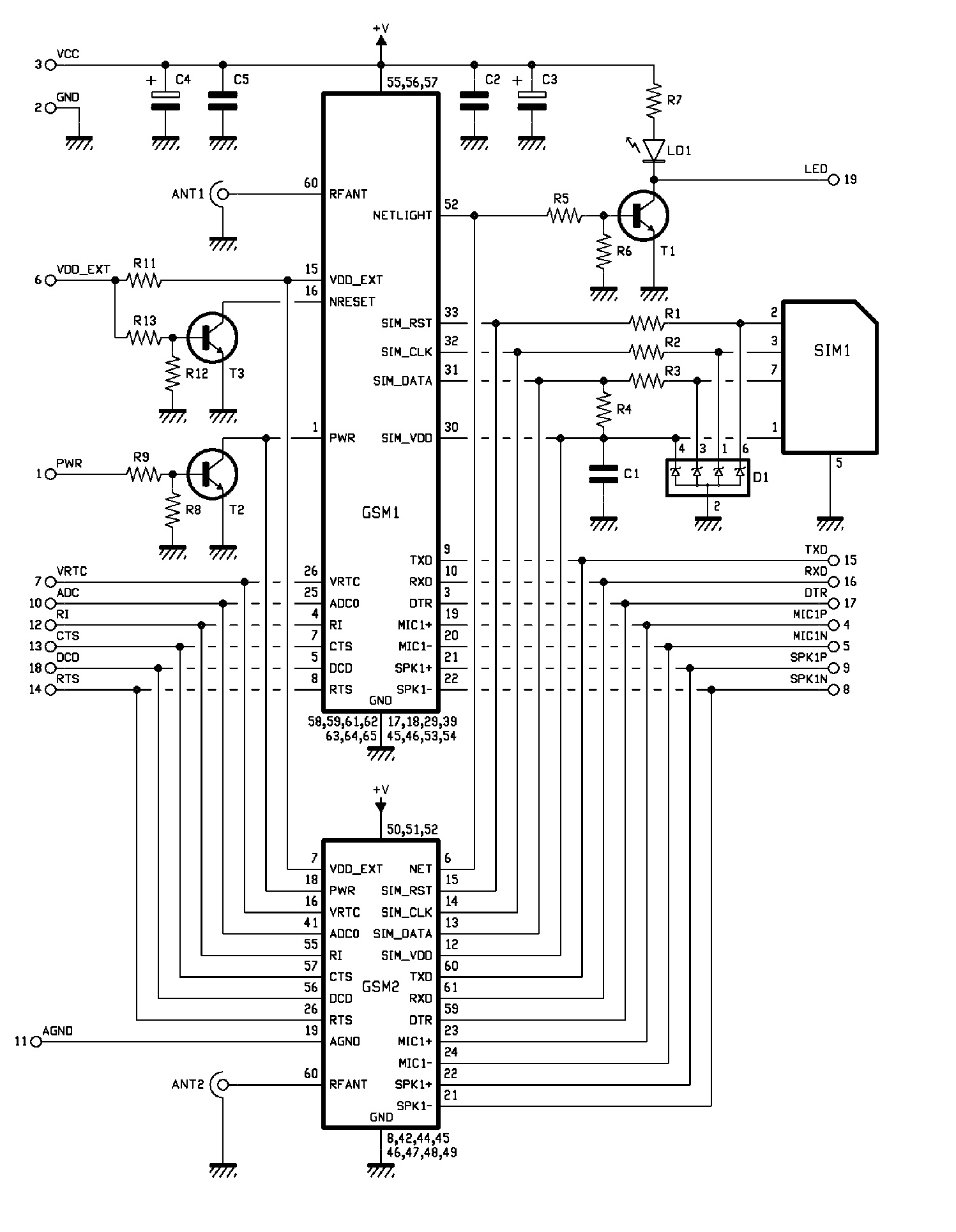

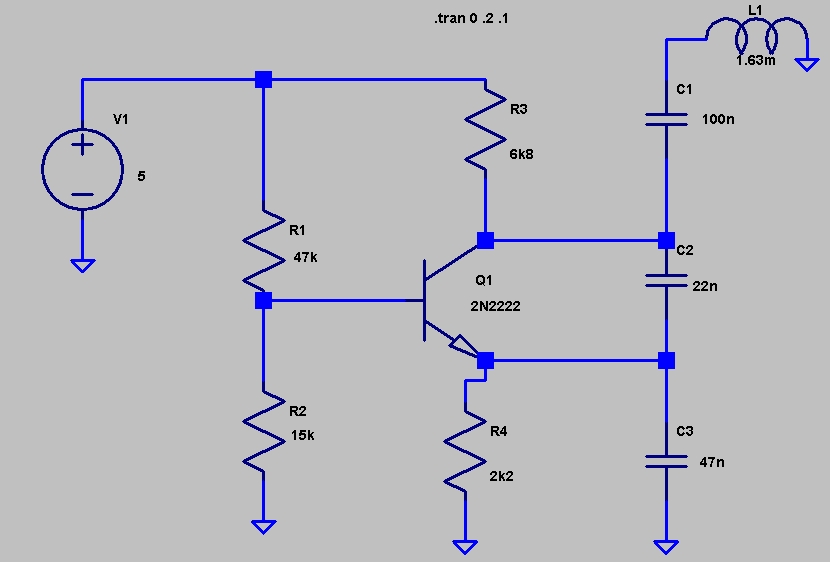

In designing a low voltage speed control circuit with a reversing switch, key components include a microcontroller or a dedicated motor driver IC for PWM control, a power MOSFET or transistor for switching, and the reversing switch itself, which can be a simple toggle switch or a more complex relay arrangement. Proper circuit protection, such as fuses or circuit breakers, should also be included to safeguard against overload conditions.

The layout of the circuit should minimize noise and interference, ensuring stable operation. It is advisable to use decoupling capacitors close to the power supply pins of the microcontroller and motor driver to filter out voltage spikes. Additionally, the use of inductors in the circuit can help smooth out current fluctuations, providing a more stable performance.

Overall, the combination of low voltage speed control and a reversing switch creates a versatile motor control solution suitable for a wide range of applications, enhancing both functionality and efficiency.Low voltage speed control gives very good starting torque and excellent speed regulation A reversing switch may be incorporated in the leads to the motor.

Low voltage speed control circuits are essential in applications where precise motor control is required, such as in robotics, conveyor systems, and electric vehicles. The effective starting torque is crucial for applications that involve heavy loads or require immediate acceleration. This can be achieved through pulse-width modulation (PWM) techniques, which allow for the adjustment of the voltage applied to the motor, thus controlling its speed while maintaining high torque levels.

The integration of a reversing switch further enhances the functionality of the motor control system. This switch can be configured to reverse the polarity of the voltage supplied to the motor, enabling bidirectional operation. This is particularly beneficial in applications where the motor must change direction frequently, such as in automated material handling or in devices that require back-and-forth motion.

In designing a low voltage speed control circuit with a reversing switch, key components include a microcontroller or a dedicated motor driver IC for PWM control, a power MOSFET or transistor for switching, and the reversing switch itself, which can be a simple toggle switch or a more complex relay arrangement. Proper circuit protection, such as fuses or circuit breakers, should also be included to safeguard against overload conditions.

The layout of the circuit should minimize noise and interference, ensuring stable operation. It is advisable to use decoupling capacitors close to the power supply pins of the microcontroller and motor driver to filter out voltage spikes. Additionally, the use of inductors in the circuit can help smooth out current fluctuations, providing a more stable performance.

Overall, the combination of low voltage speed control and a reversing switch creates a versatile motor control solution suitable for a wide range of applications, enhancing both functionality and efficiency.Low voltage speed control gives very good starting torque and excellent speed regulation A reversing switch may be incorporated in the leads to the motor.