speedcontroller TRIAC switching problem

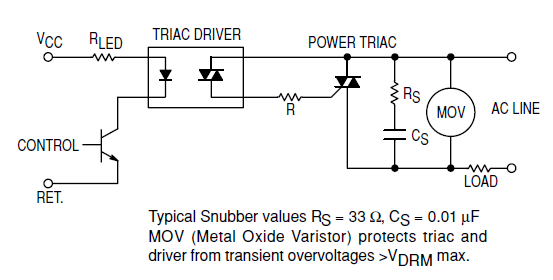

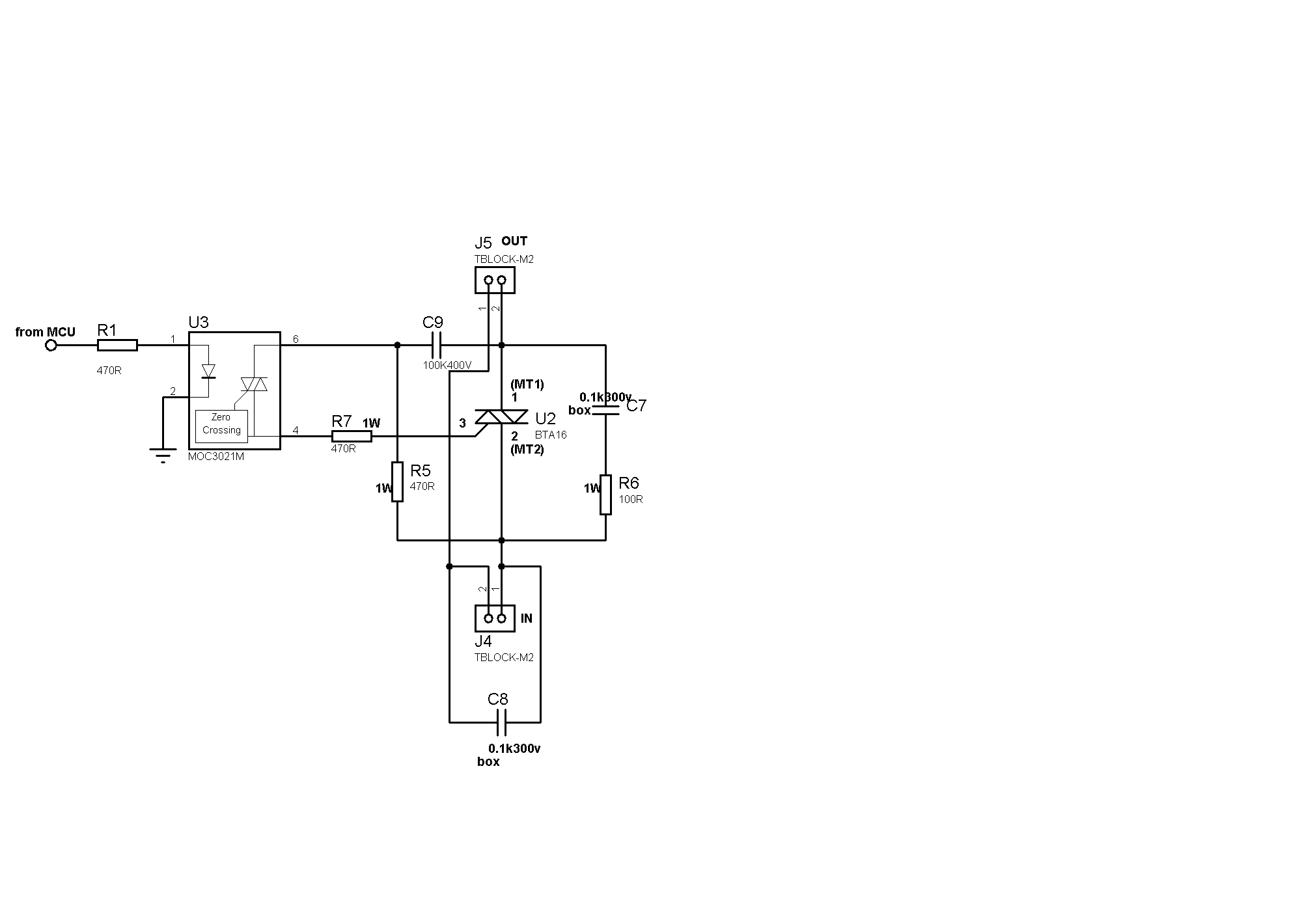

Sufficient snubbering appears to be present around the TRIAC, which should mitigate DV/DT-based switching, preventing the TRIAC from inadvertently turning on due to noise on the gate lead. The issue likely resides on the microcontroller side. When the microcontroller is in reset, all its pins are configured as inputs, which differs from having the left side of resistor R1 disconnected, as the microcontroller may have internal pull-up resistors. These internal pull-ups are typically weak and insufficient to drive the optocoupler LED strongly. Measurement across R1 may reveal a few dozen to a hundred microvolts, which could potentially trigger the optocoupler. It is advisable to redesign the microcontroller portion of the circuit so that the anode of the optocoupler LED connects to +V, while the cathode connects to the microcontroller through R1. The microcontroller will need to drive the output LOW to activate the TRIAC, thereby eliminating the transient condition when the microcontroller exits reset, during which the pin is an input and may weakly energize the LED. Additionally, incorporating an external pull-up resistor is recommended due to the involvement of line voltage, providing a stronger pull-up to ensure the optocoupler remains off. Further investigation into the larger TRIAC's switching characteristics is also suggested, particularly if it is a sensitive-gate TRIAC operating in a noisy environment, which may necessitate a reevaluation of the snubbering.

The circuit in question involves the use of a TRIAC for switching applications, typically in AC loads. The presence of snubbering components is essential to protect the TRIAC from voltage transients that could cause unintended triggering. The microcontroller plays a crucial role in controlling the TRIAC through an optocoupler, which provides electrical isolation between the high-voltage AC side and the low-voltage control side.

In this configuration, the optocoupler is utilized to isolate the microcontroller from the AC load. The redesign of the microcontroller circuit is necessary to ensure that the optocoupler operates reliably. The optocoupler's LED should be connected such that it receives a clear HIGH signal when the microcontroller intends to turn on the TRIAC. By connecting the anode of the optocoupler LED to the positive voltage supply and the cathode to the microcontroller pin via resistor R1, the microcontroller can actively control the LED state.

The choice of R1 is critical; it should be selected to limit the current to the optocoupler's LED within its specified range while ensuring that a sufficient voltage drop occurs across it when the microcontroller pin is LOW. This design modification eliminates the risk of the LED being partially illuminated due to weak pull-up currents during the reset state of the microcontroller.

Additionally, the incorporation of an external pull-up resistor on the microcontroller pin is advisable for enhanced reliability in maintaining the optocoupler in an OFF state when not actively driven LOW. This measure is particularly important when dealing with line voltages, where unintended triggering could pose safety hazards.

Finally, analyzing the specifications of the TRIAC is essential, especially if it is classified as a sensitive-gate TRIAC. In environments with significant electrical noise, the characteristics of the TRIAC may necessitate further protective measures, such as improved snubbering circuits, to ensure stable operation without false triggering. The overall design should prioritize both functionality and safety in controlling AC loads through microcontroller interfacing.You already appear to have sufficient snubberring around the TRIAC which should eliminate DV/DT based switching (the TRIAC turning itself on due to noise on the gate lead) which I believe that your issue is on the micro side of things. I think your issue is as follows. When the micro is in reset, all of its pins are inputs. This isn`t quite the same thing as having the left side of R1 disconnected since the micro also probably has internal pullups. These pullups are too weak to drive the opto LED strongly, but I bet if you put a meter across R1 you will see maybe a few dozen to a hundred microvolts.

That might be enough to trigger that opto. I would rework the micro side of your circuit so that the anode of the optocoupler LED goes to +V and the cathode goes to your micro through R1; your micro will then have to drive the output LOW to turn on the TRIAC, but it will eliminate that brief moment where the micro comes out of reset and the pin is an input and drives the LED weakly. I would also add an external pull-up resistor just because you`re working with line voltage and I like the assurance of a stronger pull-up resistor to make sure the opto stays off.

I would also investigate the larger TRIAC to see what exactly its switching characteristics are. If it`s a sensitive-gate TRIAC and you have a noisy environment you may need to take a closer look at your snubberring. 🔗 External reference

The circuit in question involves the use of a TRIAC for switching applications, typically in AC loads. The presence of snubbering components is essential to protect the TRIAC from voltage transients that could cause unintended triggering. The microcontroller plays a crucial role in controlling the TRIAC through an optocoupler, which provides electrical isolation between the high-voltage AC side and the low-voltage control side.

In this configuration, the optocoupler is utilized to isolate the microcontroller from the AC load. The redesign of the microcontroller circuit is necessary to ensure that the optocoupler operates reliably. The optocoupler's LED should be connected such that it receives a clear HIGH signal when the microcontroller intends to turn on the TRIAC. By connecting the anode of the optocoupler LED to the positive voltage supply and the cathode to the microcontroller pin via resistor R1, the microcontroller can actively control the LED state.

The choice of R1 is critical; it should be selected to limit the current to the optocoupler's LED within its specified range while ensuring that a sufficient voltage drop occurs across it when the microcontroller pin is LOW. This design modification eliminates the risk of the LED being partially illuminated due to weak pull-up currents during the reset state of the microcontroller.

Additionally, the incorporation of an external pull-up resistor on the microcontroller pin is advisable for enhanced reliability in maintaining the optocoupler in an OFF state when not actively driven LOW. This measure is particularly important when dealing with line voltages, where unintended triggering could pose safety hazards.

Finally, analyzing the specifications of the TRIAC is essential, especially if it is classified as a sensitive-gate TRIAC. In environments with significant electrical noise, the characteristics of the TRIAC may necessitate further protective measures, such as improved snubbering circuits, to ensure stable operation without false triggering. The overall design should prioritize both functionality and safety in controlling AC loads through microcontroller interfacing.You already appear to have sufficient snubberring around the TRIAC which should eliminate DV/DT based switching (the TRIAC turning itself on due to noise on the gate lead) which I believe that your issue is on the micro side of things. I think your issue is as follows. When the micro is in reset, all of its pins are inputs. This isn`t quite the same thing as having the left side of R1 disconnected since the micro also probably has internal pullups. These pullups are too weak to drive the opto LED strongly, but I bet if you put a meter across R1 you will see maybe a few dozen to a hundred microvolts.

That might be enough to trigger that opto. I would rework the micro side of your circuit so that the anode of the optocoupler LED goes to +V and the cathode goes to your micro through R1; your micro will then have to drive the output LOW to turn on the TRIAC, but it will eliminate that brief moment where the micro comes out of reset and the pin is an input and drives the LED weakly. I would also add an external pull-up resistor just because you`re working with line voltage and I like the assurance of a stronger pull-up resistor to make sure the opto stays off.

I would also investigate the larger TRIAC to see what exactly its switching characteristics are. If it`s a sensitive-gate TRIAC and you have a noisy environment you may need to take a closer look at your snubberring. 🔗 External reference