Stepper Motor Controller

Stepper motors are available in several versions and sizes with a variety of operating voltages. The advantage of this general-purpose controller is that...

Stepper motors are electromechanical devices that convert electrical energy into precise mechanical movement. They are widely used in applications requiring accurate positioning and repeatability, such as in robotics, CNC machines, and 3D printers. The various versions and sizes of stepper motors allow for flexibility in design and application, accommodating different torque and speed requirements. Operating voltages for stepper motors can range from low-voltage options suitable for battery-operated devices to higher voltages for industrial applications, enhancing performance and efficiency.

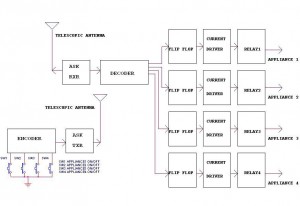

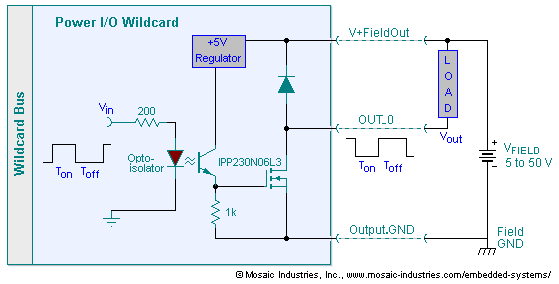

A general-purpose stepper motor controller can manage multiple stepper motors simultaneously, providing control over speed, direction, and position. The controller typically interfaces with a microcontroller or a computer, translating commands into electrical signals that drive the motors. Key features of a stepper motor controller include pulse width modulation (PWM) for efficient power delivery, current limiting to protect the motor from overheating, and microstepping capabilities to improve resolution and smoothness of motion.

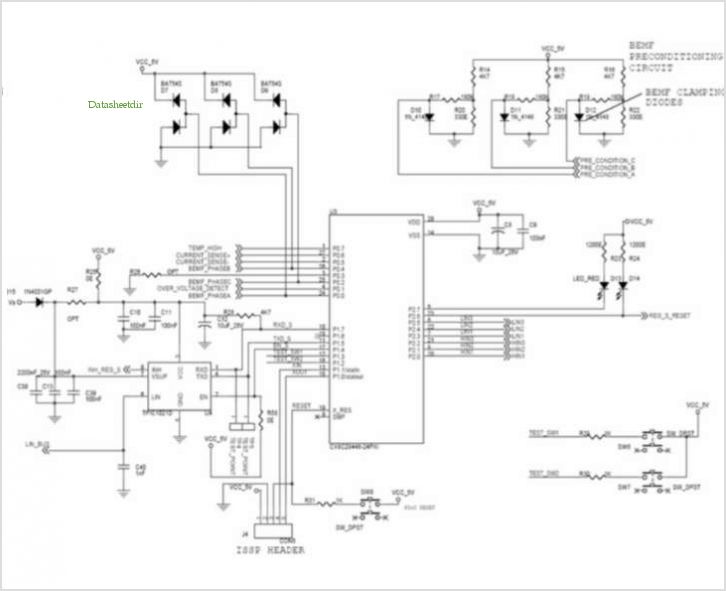

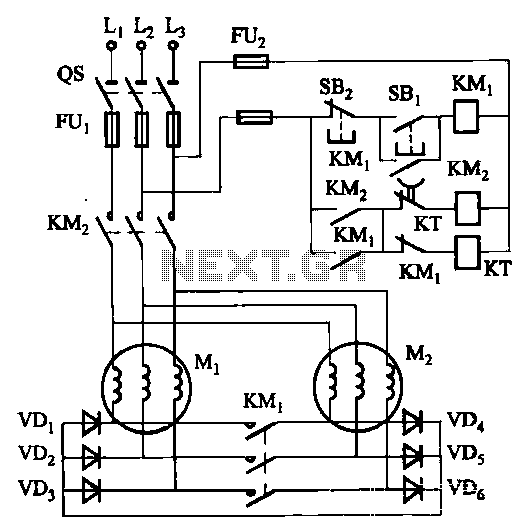

In a typical schematic, the controller would include input terminals for receiving control signals, a power supply input for the motors, and output connections to the stepper motors. Additional components may include transistors or MOSFETs to switch the motor phases, diodes for flyback protection, and capacitors for filtering noise from the power supply. Proper layout and grounding techniques are essential to ensure reliable operation and minimize electromagnetic interference (EMI). The design must also consider thermal management to prevent overheating during extended operation.

Overall, a well-designed stepper motor controller enhances the performance of stepper motors, enabling precise control in a wide range of applications.Stepper motors are available in several versions and sizes with a variety of operating voltages. The advantage of this general-purpose controller is that.. 🔗 External reference

Stepper motors are electromechanical devices that convert electrical energy into precise mechanical movement. They are widely used in applications requiring accurate positioning and repeatability, such as in robotics, CNC machines, and 3D printers. The various versions and sizes of stepper motors allow for flexibility in design and application, accommodating different torque and speed requirements. Operating voltages for stepper motors can range from low-voltage options suitable for battery-operated devices to higher voltages for industrial applications, enhancing performance and efficiency.

A general-purpose stepper motor controller can manage multiple stepper motors simultaneously, providing control over speed, direction, and position. The controller typically interfaces with a microcontroller or a computer, translating commands into electrical signals that drive the motors. Key features of a stepper motor controller include pulse width modulation (PWM) for efficient power delivery, current limiting to protect the motor from overheating, and microstepping capabilities to improve resolution and smoothness of motion.

In a typical schematic, the controller would include input terminals for receiving control signals, a power supply input for the motors, and output connections to the stepper motors. Additional components may include transistors or MOSFETs to switch the motor phases, diodes for flyback protection, and capacitors for filtering noise from the power supply. Proper layout and grounding techniques are essential to ensure reliable operation and minimize electromagnetic interference (EMI). The design must also consider thermal management to prevent overheating during extended operation.

Overall, a well-designed stepper motor controller enhances the performance of stepper motors, enabling precise control in a wide range of applications.Stepper motors are available in several versions and sizes with a variety of operating voltages. The advantage of this general-purpose controller is that.. 🔗 External reference