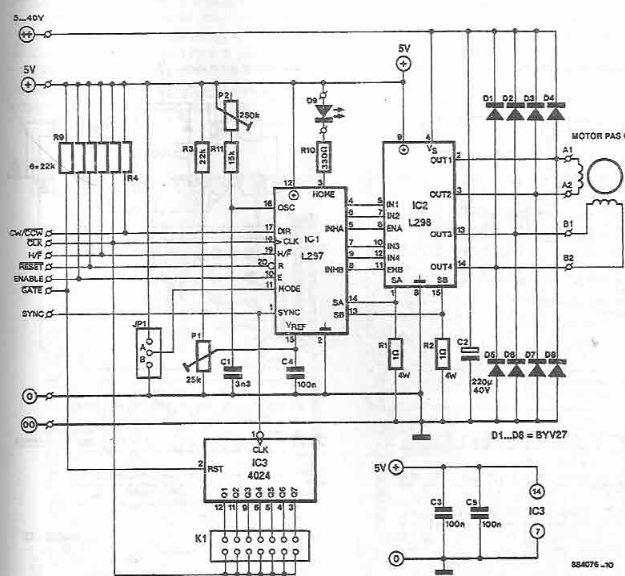

stepper motor driver circuit diagram

The L297 and L298 integrated circuits manufactured by SGS Thomson (ST) can be utilized to create a control circuit for a stepper motor, accommodating both two-phase bipolar and unipolar four-phase configurations, with a maximum current rating of 2 A per phase. This integrated motor driver produces control signals for the dual stator, enabling the selection of travel direction and the execution of full or half steps through appropriate input planning, which is TTL compatible. An additional component in the assembly, the IC3 divider, is intended to generate a clock signal when the output from the computer is programmed to set the required step frequency. The SYNC signal is derived from the L297, and the jumper block K1 allows for the selection of one of seven available clock frequencies. A power supply of 5 to 40 V is required, which does not need to be stabilized but must include filtering. The maximum stepping frequency can increase with voltage, though it should not exceed the 40 V limit.

The L297-L298 stepper motor control circuit is designed to manage the operation of stepper motors effectively. The L297 serves as the controller, generating the necessary signals to drive the L298 power driver, which provides the current to the motor coils. The circuit can handle both bipolar and unipolar stepper motors, making it versatile for various applications. The maximum current rating of 2 A ensures that the circuit can power motors with significant torque requirements.

In operation, the L297 processes input signals that determine the stepping mode, allowing for either full-step or half-step operations. Full stepping provides maximum torque, while half stepping increases resolution and smoothness of motion, which is particularly useful in applications requiring precise positioning. The TTL compatibility of the inputs allows for easy integration with microcontrollers or other digital logic devices.

The IC3 divider plays a crucial role in generating a stable clock signal, which is essential for maintaining consistent step timing. By programming the output from a computer or microcontroller, the desired step frequency can be achieved, enabling the motor to operate at various speeds. The SYNC output from the L297 can be used to synchronize other components in the system, ensuring that all parts of the circuit operate in harmony.

The jumper block K1 provides flexibility in selecting clock frequencies, with seven options available. This feature allows users to tailor the motor's performance to specific requirements, whether that be for high-speed operation or precision control.

The power supply requirements of 5 to 40 V highlight the need for adequate filtering, ensuring that voltage fluctuations do not affect the performance of the circuit. While stabilization of the power supply is not mandatory, it is advisable to implement filtering to mitigate noise, which could lead to erratic motor behavior. It is important to note that as the supply voltage increases, the maximum frequency of the steps can also increase, but care must be taken to remain within the specified limit of 40 V to prevent damage to the components.

Overall, the L297-L298 stepper motor control circuit provides a robust solution for controlling stepper motors in various applications, combining flexibility, precision, and ease of integration.Using L297-L298 integrated circuits manufactured by SGS Thomson (ST) can be made a control circuit for a stepper motor with two phase bipolar or unipolar four-phase (maximum current allowed on stage is 2 A). This integrated motor driver generates control signals for the double stator and allows selection of travel direction and execution of a full

step or half step, through proper planning its inputs, TTL compatible. Another component of the assembly, IC3 divider, is designed to provide the clock signal when the output of the computer could be programmed to branch to step frequency required. Order cycle for a given signal SYNC divider taken from L297, and the block of jumpers K1 allows selecting one of the 7 available clock frequency (frequency step).

5 and 40 V power supply should not be stabilized but is required filtering. Maximum frequency of the steps increases with voltage, but not exceeded its limit of 40 V. 🔗 External reference

The L297-L298 stepper motor control circuit is designed to manage the operation of stepper motors effectively. The L297 serves as the controller, generating the necessary signals to drive the L298 power driver, which provides the current to the motor coils. The circuit can handle both bipolar and unipolar stepper motors, making it versatile for various applications. The maximum current rating of 2 A ensures that the circuit can power motors with significant torque requirements.

In operation, the L297 processes input signals that determine the stepping mode, allowing for either full-step or half-step operations. Full stepping provides maximum torque, while half stepping increases resolution and smoothness of motion, which is particularly useful in applications requiring precise positioning. The TTL compatibility of the inputs allows for easy integration with microcontrollers or other digital logic devices.

The IC3 divider plays a crucial role in generating a stable clock signal, which is essential for maintaining consistent step timing. By programming the output from a computer or microcontroller, the desired step frequency can be achieved, enabling the motor to operate at various speeds. The SYNC output from the L297 can be used to synchronize other components in the system, ensuring that all parts of the circuit operate in harmony.

The jumper block K1 provides flexibility in selecting clock frequencies, with seven options available. This feature allows users to tailor the motor's performance to specific requirements, whether that be for high-speed operation or precision control.

The power supply requirements of 5 to 40 V highlight the need for adequate filtering, ensuring that voltage fluctuations do not affect the performance of the circuit. While stabilization of the power supply is not mandatory, it is advisable to implement filtering to mitigate noise, which could lead to erratic motor behavior. It is important to note that as the supply voltage increases, the maximum frequency of the steps can also increase, but care must be taken to remain within the specified limit of 40 V to prevent damage to the components.

Overall, the L297-L298 stepper motor control circuit provides a robust solution for controlling stepper motors in various applications, combining flexibility, precision, and ease of integration.Using L297-L298 integrated circuits manufactured by SGS Thomson (ST) can be made a control circuit for a stepper motor with two phase bipolar or unipolar four-phase (maximum current allowed on stage is 2 A). This integrated motor driver generates control signals for the double stator and allows selection of travel direction and execution of a full

step or half step, through proper planning its inputs, TTL compatible. Another component of the assembly, IC3 divider, is designed to provide the clock signal when the output of the computer could be programmed to branch to step frequency required. Order cycle for a given signal SYNC divider taken from L297, and the block of jumpers K1 allows selecting one of the 7 available clock frequency (frequency step).

5 and 40 V power supply should not be stabilized but is required filtering. Maximum frequency of the steps increases with voltage, but not exceeded its limit of 40 V. 🔗 External reference