Tachometer

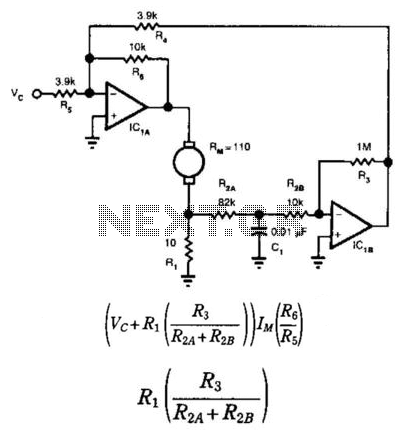

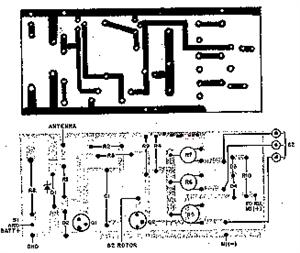

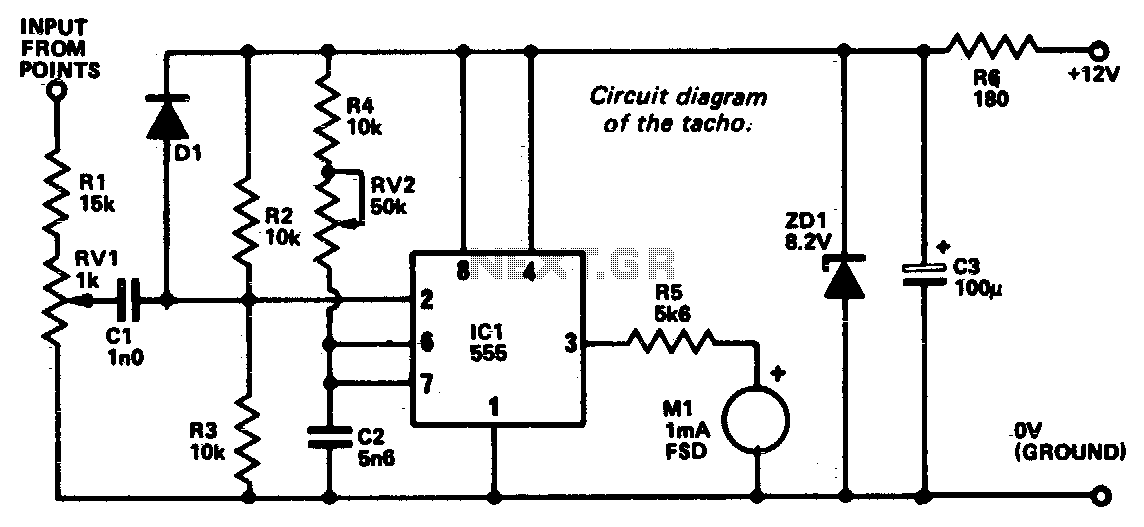

An electrical signal from the low tension side of the distributor is converted into a voltage that is proportional to engine RPM, and this voltage is displayed on a meter calibrated accordingly. The 555 timer integrated circuit (IC) operates in a monostable mode, effectively transforming the signal pulse from the breaker points into a single positive pulse. The width of this pulse is determined by the combined resistance of R4 and RV2, along with capacitor C2. Resistors R2 and R3 set a voltage of approximately 4 volts at pin 2 of IC1. The IC is triggered when this voltage drops below approximately 2 volts (one-third of the supply voltage), which occurs due to the voltage swing when the breaker points open. An adjustment potentiometer, RV1, allows for setting the input level to prevent false triggering. A Zener diode, ZD1, along with a 180-ohm resistor, stabilizes the unit against voltage fluctuations.

The circuit utilizes a 555 timer IC configured in monostable mode to facilitate the conversion of the electrical signal derived from the low tension side of the distributor into a usable voltage signal that reflects the engine's RPM. In this configuration, the 555 timer generates a single output pulse in response to a triggering event, which is the closure of the breaker points in the ignition system. The timing of this pulse is crucial, as it determines the frequency of the output signal that corresponds to the engine speed.

The components R4 and RV2 form a voltage divider that establishes the duration of the output pulse, which is directly related to the engine speed. The capacitor C2 integrates the signal, smoothing out fluctuations and ensuring that the pulse width remains stable during operation. Resistors R2 and R3 serve a dual purpose; they provide a reference voltage to pin 2 of the 555 timer and ensure that the timer is triggered only when the voltage falls below a specific threshold, which is indicative of the opening of the breaker points.

To enhance the reliability of the circuit, an adjustment potentiometer RV1 is included, allowing the user to fine-tune the input signal level. This adjustment is essential to avoid false triggering, which could occur due to noise or other transient signals present in the electrical system. The Zener diode ZD1, in conjunction with a 180-ohm resistor, acts as a voltage regulator, ensuring that the circuit operates within a stable voltage range despite variations in the input voltage, thus protecting the 555 timer and other components from potential damage due to over-voltage conditions.

Overall, this circuit design effectively translates the mechanical operation of the engine into a measurable electrical signal, providing valuable feedback for monitoring engine performance and facilitating diagnostics.An electrical signal taken from the low tension side of the distributor is converted into a voltage proportional to engine rpm and this voltage is displayed on a meter calibrated accordingly. The 555 timer IC is used as a monostable which, in effect, converts the signal pulse from the breaker points to a single positive pulse the width of which is determined by the value of R4 + RV2 and C2.

Resistors R2 and R3 seta voltage of about 4 volts at pin 2 of ICl. The IC is triggered if this voltage is reduced to less than approximately 2 volts (Ys of supply voltage), and this occurs due to the voltage swing when the breaker points open An adjustment potentiometer RV1 enables the input level to be set to avoid false triggering. Zener diode ZD1 and the 180 ohm resistor stabilize the unit against voltage variations. 🔗 External reference

The circuit utilizes a 555 timer IC configured in monostable mode to facilitate the conversion of the electrical signal derived from the low tension side of the distributor into a usable voltage signal that reflects the engine's RPM. In this configuration, the 555 timer generates a single output pulse in response to a triggering event, which is the closure of the breaker points in the ignition system. The timing of this pulse is crucial, as it determines the frequency of the output signal that corresponds to the engine speed.

The components R4 and RV2 form a voltage divider that establishes the duration of the output pulse, which is directly related to the engine speed. The capacitor C2 integrates the signal, smoothing out fluctuations and ensuring that the pulse width remains stable during operation. Resistors R2 and R3 serve a dual purpose; they provide a reference voltage to pin 2 of the 555 timer and ensure that the timer is triggered only when the voltage falls below a specific threshold, which is indicative of the opening of the breaker points.

To enhance the reliability of the circuit, an adjustment potentiometer RV1 is included, allowing the user to fine-tune the input signal level. This adjustment is essential to avoid false triggering, which could occur due to noise or other transient signals present in the electrical system. The Zener diode ZD1, in conjunction with a 180-ohm resistor, acts as a voltage regulator, ensuring that the circuit operates within a stable voltage range despite variations in the input voltage, thus protecting the 555 timer and other components from potential damage due to over-voltage conditions.

Overall, this circuit design effectively translates the mechanical operation of the engine into a measurable electrical signal, providing valuable feedback for monitoring engine performance and facilitating diagnostics.An electrical signal taken from the low tension side of the distributor is converted into a voltage proportional to engine rpm and this voltage is displayed on a meter calibrated accordingly. The 555 timer IC is used as a monostable which, in effect, converts the signal pulse from the breaker points to a single positive pulse the width of which is determined by the value of R4 + RV2 and C2.

Resistors R2 and R3 seta voltage of about 4 volts at pin 2 of ICl. The IC is triggered if this voltage is reduced to less than approximately 2 volts (Ys of supply voltage), and this occurs due to the voltage swing when the breaker points open An adjustment potentiometer RV1 enables the input level to be set to avoid false triggering. Zener diode ZD1 and the 180 ohm resistor stabilize the unit against voltage variations. 🔗 External reference