Tachometer circuit

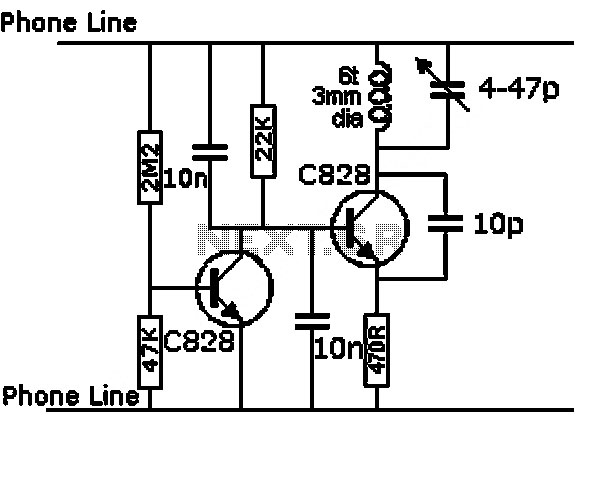

This is a simple circuit that functions as a tachometer. It operates as a frequency-to-current converter, transforming the incoming signal into a proportional current to drive the meter. The deflection on the ammeter correlates directly with the frequency of the incoming signal. To utilize this circuit as an automobile tachometer, input terminal A should be connected to the spark plug cable, while terminal B must be connected to the vehicle's ground. For calibration, set resistor R2 to 25K and R4 to 5K. After powering the circuit, feed a 60Hz square wave signal from a function generator into input terminal A. Adjust R2 until the meter reads 0.36 mA, which corresponds to 3600 RPM. Disconnect the input signal and adjust R3 to ensure the meter shows 0 mA. Reconnect the 60Hz signal; if the meter does not display 0.36 mA, adjust R4 accordingly. A properly calibrated circuit will read 0 mA at 0 Hz and 0.36 mA at 60 Hz. The ignition voltage from the spark plug terminal is in the kilovolt range. Ensure the engine is OFF while making connections, and exercise caution to avoid shock hazards. This circuit should only be attempted by individuals with sufficient knowledge and experience in automobile electrical systems. The creator assumes no responsibility for any mishaps.

The described tachometer circuit serves as an effective tool for measuring the rotational speed of an engine by interpreting the frequency of the signal generated by the spark plug. The primary components of the circuit include a frequency-to-current converter, an ammeter for displaying the current output, and several resistors for calibration and adjustment purposes.

The operation begins with the connection of terminal A to the spark plug cable, which serves as the signal input. The spark plug generates a high-voltage pulse each time the engine fires, producing a frequency that correlates with the engine's RPM. Terminal B connects to the vehicle's ground to complete the circuit.

Calibration of the circuit is crucial for accurate readings. Initially, resistors R2 and R4 are set to 25K and 5K, respectively. The circuit is powered, and a 60Hz square wave signal is introduced via a function generator. This frequency is chosen as it represents 3600 RPM, a standard reference point for tachometers. Adjusting R2 allows the current output to be set to 0.36 mA, which corresponds to the desired RPM.

After this adjustment, R3 is calibrated to ensure that the meter reads 0 mA when there is no input signal. This step is essential for establishing a baseline reading. If the meter does not reflect the expected 0.36 mA when the 60Hz signal is reintroduced, R4 can be fine-tuned to correct the output.

Safety precautions are paramount due to the high voltage present at the spark plug. The engine must be turned off during the initial setup and calibration to prevent accidental shocks. This circuit design is intended for individuals with a solid understanding of automotive electrical systems, as improper handling can lead to dangerous situations. The circuit's simplicity and effectiveness make it a valuable addition to automotive diagnostics, provided it is used responsibly and with the necessary expertise.Here is a simple circuit that can be used as a tachometer. The circuit is basically a frequency to current converter which converts the incoming signal into a proportional current to drive the meter. The deflection on the ammeter will be proportional to the frequency of the incoming signal. For using this circuit as an automobile tachometer, the i nput terminal A should be connected to the spark plug cable and terminal B should be connected to the vehicles ground. For calibrating the circuit, set R2 at 25K and R4 at 5K. Power up the circuit and feed the input terminal with a 60Hz square wave form your function generator.

Adjust R2 so that the meter shows 0. 36 mA (equal to 3600rpm). Now disconnect the input signal and adjust R3 so that the meter shows 0mA. Now connect the 60Hz signal again and if the meter does not show 0. 36mA adjust R4. A completely calibrated circuit will show 0mA at 0Hz and 0. 36mA at 60Hz. The ignition voltage from the spark plug terminal is in the Kilo volt rage. The engine must be OFF while making connections and you must be very careful to avoid shock hazards. Try this circuit on your automobile only if you have sufficient knowledge and experience on automobile electricals. I have no responsibility on any mishap. 🔗 External reference

The described tachometer circuit serves as an effective tool for measuring the rotational speed of an engine by interpreting the frequency of the signal generated by the spark plug. The primary components of the circuit include a frequency-to-current converter, an ammeter for displaying the current output, and several resistors for calibration and adjustment purposes.

The operation begins with the connection of terminal A to the spark plug cable, which serves as the signal input. The spark plug generates a high-voltage pulse each time the engine fires, producing a frequency that correlates with the engine's RPM. Terminal B connects to the vehicle's ground to complete the circuit.

Calibration of the circuit is crucial for accurate readings. Initially, resistors R2 and R4 are set to 25K and 5K, respectively. The circuit is powered, and a 60Hz square wave signal is introduced via a function generator. This frequency is chosen as it represents 3600 RPM, a standard reference point for tachometers. Adjusting R2 allows the current output to be set to 0.36 mA, which corresponds to the desired RPM.

After this adjustment, R3 is calibrated to ensure that the meter reads 0 mA when there is no input signal. This step is essential for establishing a baseline reading. If the meter does not reflect the expected 0.36 mA when the 60Hz signal is reintroduced, R4 can be fine-tuned to correct the output.

Safety precautions are paramount due to the high voltage present at the spark plug. The engine must be turned off during the initial setup and calibration to prevent accidental shocks. This circuit design is intended for individuals with a solid understanding of automotive electrical systems, as improper handling can lead to dangerous situations. The circuit's simplicity and effectiveness make it a valuable addition to automotive diagnostics, provided it is used responsibly and with the necessary expertise.Here is a simple circuit that can be used as a tachometer. The circuit is basically a frequency to current converter which converts the incoming signal into a proportional current to drive the meter. The deflection on the ammeter will be proportional to the frequency of the incoming signal. For using this circuit as an automobile tachometer, the i nput terminal A should be connected to the spark plug cable and terminal B should be connected to the vehicles ground. For calibrating the circuit, set R2 at 25K and R4 at 5K. Power up the circuit and feed the input terminal with a 60Hz square wave form your function generator.

Adjust R2 so that the meter shows 0. 36 mA (equal to 3600rpm). Now disconnect the input signal and adjust R3 so that the meter shows 0mA. Now connect the 60Hz signal again and if the meter does not show 0. 36mA adjust R4. A completely calibrated circuit will show 0mA at 0Hz and 0. 36mA at 60Hz. The ignition voltage from the spark plug terminal is in the Kilo volt rage. The engine must be OFF while making connections and you must be very careful to avoid shock hazards. Try this circuit on your automobile only if you have sufficient knowledge and experience on automobile electricals. I have no responsibility on any mishap. 🔗 External reference