Temperature Controller

Wine doesn't like subzero temperatures, and during wintertime, my wine cellar got pretty cold. There was an electric heating element, but the thermostat was broken, so it was either full burn or nothing. That's how the temperature monitor/controller came to be. It was an obvious task for a small processor and I've always wanted to test the Dallas temperature sensors. So, I designed this little device which could monitor the temperature and control the heater.

The wine cellar temperature monitor/controller is designed to maintain an optimal temperature for wine storage, typically between 10°C and 15°C (50°F and 59°F). The system incorporates a microcontroller, such as an Arduino or a similar low-power processor, which serves as the central processing unit for the temperature monitoring and control logic.

The primary sensor used in this application is the Dallas temperature sensor, specifically the DS18B20. This digital temperature sensor communicates with the microcontroller via the One-Wire protocol, allowing for easy integration and multiple sensor connections on a single data line. The DS18B20 is capable of providing accurate temperature readings within a range of -55°C to +125°C, making it suitable for monitoring the wine cellar environment.

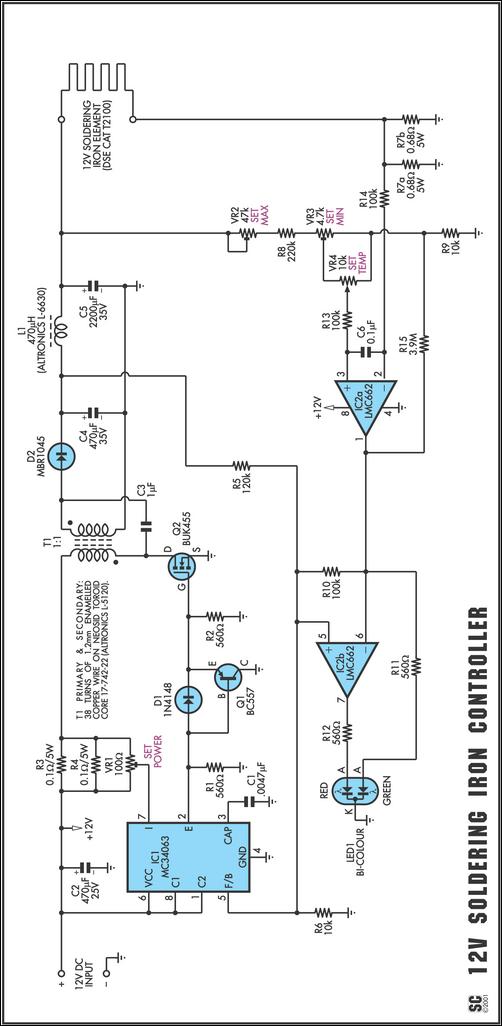

To control the heating element, a solid-state relay (SSR) or a mechanical relay is utilized, which can handle the AC voltage and current required by the heating element. The microcontroller processes the temperature readings from the DS18B20 and compares them to a predefined setpoint. If the temperature falls below the setpoint, the microcontroller activates the relay to turn on the heating element. Conversely, when the desired temperature is reached, the relay is deactivated, cutting power to the heater.

Additionally, the system may be equipped with an LCD display or LED indicators to provide real-time feedback on the current temperature and the status of the heating element. This user interface allows for easy monitoring and adjustment of the temperature setpoint.

Power supply requirements for the system can be met using a standard AC to DC power adapter, which converts the mains voltage to a suitable level for the microcontroller and sensors. Proper circuit protection, such as fuses and transient voltage suppression devices, should be included in the design to safeguard against electrical faults.

Overall, this temperature monitor/controller serves as an effective solution for maintaining the ideal conditions necessary for wine preservation, utilizing modern electronic components and straightforward programming logic.Wine doesn`t like subzero temperatures, and during wintertime, my "winecellar" got pretty cold. There was an electric heating element, but the thermostat was broken, so it was either full burn or nothing. That`s how the temperature monitor/controller came to be. It was an obvious task for a small processor and I`ve always wanted to test the Dallas temperature sensors.

So, I designed this little device which could monitor the temperature and control the heater. 🔗 External reference

The wine cellar temperature monitor/controller is designed to maintain an optimal temperature for wine storage, typically between 10°C and 15°C (50°F and 59°F). The system incorporates a microcontroller, such as an Arduino or a similar low-power processor, which serves as the central processing unit for the temperature monitoring and control logic.

The primary sensor used in this application is the Dallas temperature sensor, specifically the DS18B20. This digital temperature sensor communicates with the microcontroller via the One-Wire protocol, allowing for easy integration and multiple sensor connections on a single data line. The DS18B20 is capable of providing accurate temperature readings within a range of -55°C to +125°C, making it suitable for monitoring the wine cellar environment.

To control the heating element, a solid-state relay (SSR) or a mechanical relay is utilized, which can handle the AC voltage and current required by the heating element. The microcontroller processes the temperature readings from the DS18B20 and compares them to a predefined setpoint. If the temperature falls below the setpoint, the microcontroller activates the relay to turn on the heating element. Conversely, when the desired temperature is reached, the relay is deactivated, cutting power to the heater.

Additionally, the system may be equipped with an LCD display or LED indicators to provide real-time feedback on the current temperature and the status of the heating element. This user interface allows for easy monitoring and adjustment of the temperature setpoint.

Power supply requirements for the system can be met using a standard AC to DC power adapter, which converts the mains voltage to a suitable level for the microcontroller and sensors. Proper circuit protection, such as fuses and transient voltage suppression devices, should be included in the design to safeguard against electrical faults.

Overall, this temperature monitor/controller serves as an effective solution for maintaining the ideal conditions necessary for wine preservation, utilizing modern electronic components and straightforward programming logic.Wine doesn`t like subzero temperatures, and during wintertime, my "winecellar" got pretty cold. There was an electric heating element, but the thermostat was broken, so it was either full burn or nothing. That`s how the temperature monitor/controller came to be. It was an obvious task for a small processor and I`ve always wanted to test the Dallas temperature sensors.

So, I designed this little device which could monitor the temperature and control the heater. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713