The Accelerometer Circuit

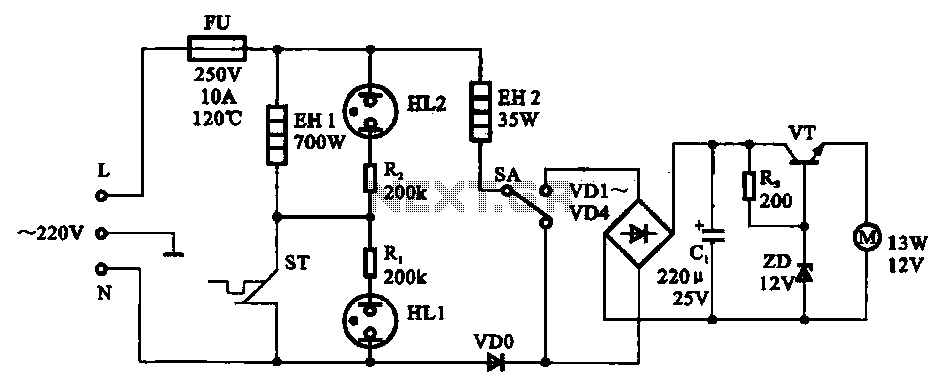

The schematic for this tutorial is straightforward. It involves connecting the ADXL320 sensor to the PIC microcontroller and an LED. The power supply is assumed to be a +5V battery to power the PIC. A custom power circuit can be designed, or a battery array can be utilized, depending on preference. The PIC serves as the central processing unit of the circuit. It will sample data through its Analog-to-Digital (A/D) converters, which will be evaluated to determine the tilt or acceleration of the board. The sensor outputs an analog signal to the PIC, which is interpreted based on the change in voltage to measure the gravitational force (g's) being experienced. The circuit includes a single LED, which will blink at varying rates to indicate the amount of acceleration or tilt detected by the ADXL320 sensor. This functionality will be implemented through software running on the PIC.

The schematic consists of the following key components: the ADXL320 accelerometer, the PIC microcontroller, and an LED indicator. The ADXL320 sensor is a three-axis accelerometer capable of providing analog output signals corresponding to acceleration along the X, Y, and Z axes. The output signals are fed into the PIC's A/D converter inputs.

The PIC microcontroller is programmed to continuously sample the analog voltage signals from the ADXL320. The software will convert these analog values into digital representations that correspond to the acceleration forces acting on the sensor. By analyzing these values, the microcontroller determines the tilt angle or the rate of acceleration.

The LED is connected to one of the output pins of the PIC. The blinking frequency of the LED is modulated based on the processed acceleration data. For instance, a higher acceleration detected by the ADXL320 will result in a faster blinking rate of the LED, while lower acceleration will cause a slower blink. This visual feedback provides an intuitive way to observe the sensor's response to motion.

The power supply circuitry must ensure that the PIC receives a stable +5V supply. This can be achieved using a simple battery configuration or a more complex power management circuit, depending on the application requirements. Proper decoupling capacitors should be included near the power pins of the PIC and ADXL320 to filter any noise and ensure stable operation.

Overall, this circuit provides a basic yet effective demonstration of interfacing an accelerometer with a microcontroller, showcasing how sensor data can be processed and represented visually through an LED indicator.The schematic is very simple for this tutorial. It is just a matter of wiring up the ADXL320 sensor to the PIC and the LED. The power circuitry assumes you have a battery of +5v to power the PIC. You can create your own custom circuitry for this or just use a battery array. whatever you like. The PIC is the brains of the circuit. Using the A/D`s on the PIC data samples will be taken as input and then evaluated. Based off different inputs the LEDs will blink faster or slower to show how much the board has been tilted or accelerated. This sensor will output an analog signal to the PIC to be interpreted. The signal is measured by its change in voltage when you want to find out how many g`s are currently being `pulled`.

This is just one single LED added to the circuit. Depending on how fast it is blink will tell us how much acceleration or tilt is being applied to the ADXL320 sensor. This will of course all be done in software in the PIC. 🔗 External reference

The schematic consists of the following key components: the ADXL320 accelerometer, the PIC microcontroller, and an LED indicator. The ADXL320 sensor is a three-axis accelerometer capable of providing analog output signals corresponding to acceleration along the X, Y, and Z axes. The output signals are fed into the PIC's A/D converter inputs.

The PIC microcontroller is programmed to continuously sample the analog voltage signals from the ADXL320. The software will convert these analog values into digital representations that correspond to the acceleration forces acting on the sensor. By analyzing these values, the microcontroller determines the tilt angle or the rate of acceleration.

The LED is connected to one of the output pins of the PIC. The blinking frequency of the LED is modulated based on the processed acceleration data. For instance, a higher acceleration detected by the ADXL320 will result in a faster blinking rate of the LED, while lower acceleration will cause a slower blink. This visual feedback provides an intuitive way to observe the sensor's response to motion.

The power supply circuitry must ensure that the PIC receives a stable +5V supply. This can be achieved using a simple battery configuration or a more complex power management circuit, depending on the application requirements. Proper decoupling capacitors should be included near the power pins of the PIC and ADXL320 to filter any noise and ensure stable operation.

Overall, this circuit provides a basic yet effective demonstration of interfacing an accelerometer with a microcontroller, showcasing how sensor data can be processed and represented visually through an LED indicator.The schematic is very simple for this tutorial. It is just a matter of wiring up the ADXL320 sensor to the PIC and the LED. The power circuitry assumes you have a battery of +5v to power the PIC. You can create your own custom circuitry for this or just use a battery array. whatever you like. The PIC is the brains of the circuit. Using the A/D`s on the PIC data samples will be taken as input and then evaluated. Based off different inputs the LEDs will blink faster or slower to show how much the board has been tilted or accelerated. This sensor will output an analog signal to the PIC to be interpreted. The signal is measured by its change in voltage when you want to find out how many g`s are currently being `pulled`.

This is just one single LED added to the circuit. Depending on how fast it is blink will tell us how much acceleration or tilt is being applied to the ADXL320 sensor. This will of course all be done in software in the PIC. 🔗 External reference