The built-in ultrasonic flow measurement of stand pipe based on correlation method is designed (

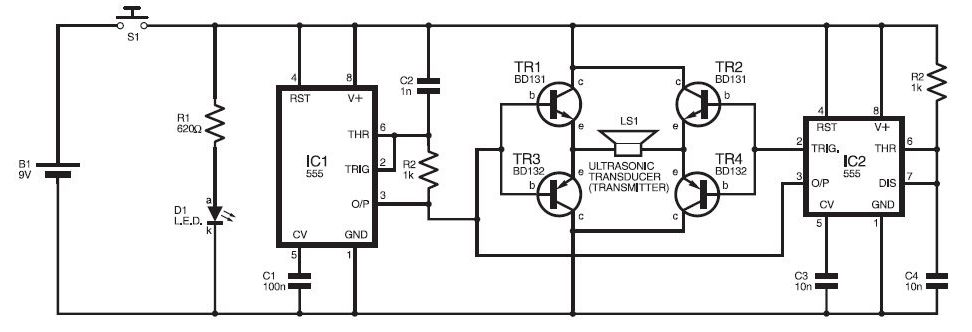

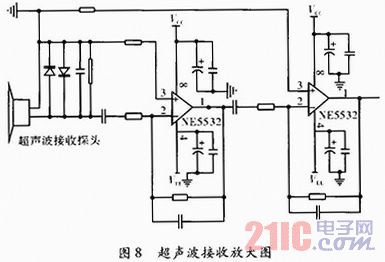

In industrial production, flow measurement is a widely used physical quantity measurement. Under specific circumstances, such as when vertical externally positioned installation probes are required for challenging pipelines like oil wells, it is necessary to design instruments and equipment to test the flow rate for intraductal installation. In practical conditions, the probe built into the liquid can interfere with the waveform of the emitted and received signals. Therefore, the ultrasonic flowmeter, designed based on the correlation method, is primarily adopted to measure fluid flow. The measurement system can utilize sensors to detect flow noise, demonstrating strong noise resistance. The correlation method measures the delayed characteristics, ensuring that the measurement results remain unaffected by interference noise. Two sets of probes are employed to perform relevant operations on the received signals, resulting in improved waveform quality. When ultrasonic waves travel through the liquid, the transmission time varies depending on whether the direction is aligned with or against the liquid flow. In this design, the probes are positioned relative to immersion in the liquid, enabling integral detection within the duct. As illustrated in the diagram, two ultrasonic transmitters (S1 and S2) and receivers (R1 and R2) are placed at a constant distance L, allowing for measurements in both downstream and counter-current directions.

The formulas used in this context are as follows: C represents the propagation velocity of ultrasonic waves in the resting fluid; V denotes the fluid flow speed; T1 is the time required for the signal to travel downstream; and T2 is the time required for the signal to travel against the flow. The signals received and transmitted are correlated to measure transmission time. The correlation method involves assessing the affinity between the two-way signals, where one signal experiences a relative delay compared to the other. By calculating the cross-correlation function of the two-way signals, the corresponding time can be determined, specifically at the peak point of the cross-correlation function, which indicates the transition time. The ultrasonic transducer emits a signal (xt), while the receiver detects a signal (yt), which is theoretically a time-delayed version of xt. Although both signals share similar waveforms, they differ in timing, with the time difference expressed as t = t2 - t1. The final correlation function, denoted as Rxy, provides a comprehensive understanding of the flow measurement process.

This approach ensures accurate flow measurement in challenging environments, utilizing the principles of ultrasonic technology and sophisticated signal processing techniques to mitigate the effects of noise and interference.In industrial production, flow measurement is to employ the extensive measurement physical quantity. Under special circumstances, when for instance vertical externally positioned installation probes of difficult pipeline such as the oil well, etc. , need to design a kind of instrument and equipment to test the flowrate to intraductal installation.

In actual conditions, because probe built-in in examine in the liquid, the waveform of emitting-receiving will be interfered with, it is directed primarily to adopting the supersonic flowmeter that principle is designed of the correlation method to measure fluid-flow so originally design. The noise of flowing can utilize the sensor to measure in the measuring system, it is that the ability to resist noise is strong and the correlation method measures the delayed characteristic, so long as the interference noise correlates with received signal no, the measuring result is free of interference noise, adopt the two set probe, do relevant operation of the signal and signal received to deal with, obtain better waveform.

When travelling in the liquid in supersonic wave, when being the same as liquid flow direction or opposite, ultrasonic transmission time is different. In design this, adopt probe to be relative soaking in examine in the liquid, some of integral detection are intraductal to go on.

Design and is shown as in Fig. 1 if in the distance of the constant length L, put the ultrasonic sender S1, S2 and receiver R1, R2 of two set separately, to having downstream and counter-currently. Formula 1 And formula 2 China, C is the supersonic wave in the resting fluid inner propagation velocity; V is the speed of the fluid flow; T1 spreads and sows required time for being suitable; T2 sows required time in order to go against to spread.

It is relevant to do by signal and received signal, can measure transmission time. The correlation method mainly refers to the affinity between the two-way signals, the signals of No. one among them are relatively delay on of having one time of another No. signal. Calculate the cross-correlation function of the two-way signal, and calculate and correspond to correspondent time, namely among the peak point of cross-correlation function is correspondent, get transition time. The ultrasonic transducer sends out a signal xt, The ultrasonic transducer receives a signal yt, Signal yt in theory It is a signal xt One piece time delay signal, the two pieces of signal one waveform is similar, but not time interval in time shaft t=t2-t1Two set signal, last correlation function Rxy of signal, The expression is In industrial production, flow measurement is to employ the extensive measurement physical quantity.

Under special circumstances, when for instance vertical externally positioned installation probes of difficult pipeline such as the oil well, etc. , need to design a kind of instrument and equipment to test the flowrate to intraductal installation.

In actual conditions, because probe built-in in examine in the liquid, the waveform of emitting-receiving will be interfered with, it is directed primarily to adopting the supersonic flowmeter that principle is designed of the correlation method to measure fluid-flow so originally design. The noise of flowing can utilize the sensor to measure in the measuring system, it is that the ability to resist noise is strong and the correlation method measures the delayed characteristic, so long as the interference noise correlates with received signal no, the measuring result is free of interference noise, adopt the two set probe, do relevant operation of the signal and signal received to deal with, obtain better waveform.

When travelling in the liquid in supersonic wave, when being the same as liquid flow direction or opposite, ultrasonic transmission time is different. In design this, adopt probe to be relative soaking in examine in the liquid, it measures some to be 🔗 External reference

The formulas used in this context are as follows: C represents the propagation velocity of ultrasonic waves in the resting fluid; V denotes the fluid flow speed; T1 is the time required for the signal to travel downstream; and T2 is the time required for the signal to travel against the flow. The signals received and transmitted are correlated to measure transmission time. The correlation method involves assessing the affinity between the two-way signals, where one signal experiences a relative delay compared to the other. By calculating the cross-correlation function of the two-way signals, the corresponding time can be determined, specifically at the peak point of the cross-correlation function, which indicates the transition time. The ultrasonic transducer emits a signal (xt), while the receiver detects a signal (yt), which is theoretically a time-delayed version of xt. Although both signals share similar waveforms, they differ in timing, with the time difference expressed as t = t2 - t1. The final correlation function, denoted as Rxy, provides a comprehensive understanding of the flow measurement process.

This approach ensures accurate flow measurement in challenging environments, utilizing the principles of ultrasonic technology and sophisticated signal processing techniques to mitigate the effects of noise and interference.In industrial production, flow measurement is to employ the extensive measurement physical quantity. Under special circumstances, when for instance vertical externally positioned installation probes of difficult pipeline such as the oil well, etc. , need to design a kind of instrument and equipment to test the flowrate to intraductal installation.

In actual conditions, because probe built-in in examine in the liquid, the waveform of emitting-receiving will be interfered with, it is directed primarily to adopting the supersonic flowmeter that principle is designed of the correlation method to measure fluid-flow so originally design. The noise of flowing can utilize the sensor to measure in the measuring system, it is that the ability to resist noise is strong and the correlation method measures the delayed characteristic, so long as the interference noise correlates with received signal no, the measuring result is free of interference noise, adopt the two set probe, do relevant operation of the signal and signal received to deal with, obtain better waveform.

When travelling in the liquid in supersonic wave, when being the same as liquid flow direction or opposite, ultrasonic transmission time is different. In design this, adopt probe to be relative soaking in examine in the liquid, some of integral detection are intraductal to go on.

Design and is shown as in Fig. 1 if in the distance of the constant length L, put the ultrasonic sender S1, S2 and receiver R1, R2 of two set separately, to having downstream and counter-currently. Formula 1 And formula 2 China, C is the supersonic wave in the resting fluid inner propagation velocity; V is the speed of the fluid flow; T1 spreads and sows required time for being suitable; T2 sows required time in order to go against to spread.

It is relevant to do by signal and received signal, can measure transmission time. The correlation method mainly refers to the affinity between the two-way signals, the signals of No. one among them are relatively delay on of having one time of another No. signal. Calculate the cross-correlation function of the two-way signal, and calculate and correspond to correspondent time, namely among the peak point of cross-correlation function is correspondent, get transition time. The ultrasonic transducer sends out a signal xt, The ultrasonic transducer receives a signal yt, Signal yt in theory It is a signal xt One piece time delay signal, the two pieces of signal one waveform is similar, but not time interval in time shaft t=t2-t1Two set signal, last correlation function Rxy of signal, The expression is In industrial production, flow measurement is to employ the extensive measurement physical quantity.

Under special circumstances, when for instance vertical externally positioned installation probes of difficult pipeline such as the oil well, etc. , need to design a kind of instrument and equipment to test the flowrate to intraductal installation.

In actual conditions, because probe built-in in examine in the liquid, the waveform of emitting-receiving will be interfered with, it is directed primarily to adopting the supersonic flowmeter that principle is designed of the correlation method to measure fluid-flow so originally design. The noise of flowing can utilize the sensor to measure in the measuring system, it is that the ability to resist noise is strong and the correlation method measures the delayed characteristic, so long as the interference noise correlates with received signal no, the measuring result is free of interference noise, adopt the two set probe, do relevant operation of the signal and signal received to deal with, obtain better waveform.

When travelling in the liquid in supersonic wave, when being the same as liquid flow direction or opposite, ultrasonic transmission time is different. In design this, adopt probe to be relative soaking in examine in the liquid, it measures some to be 🔗 External reference