Time Domain Reflectometer (TDR)

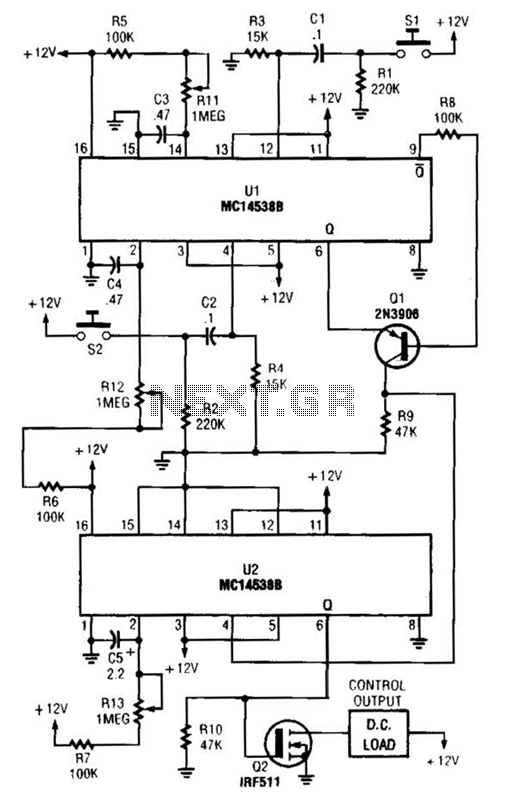

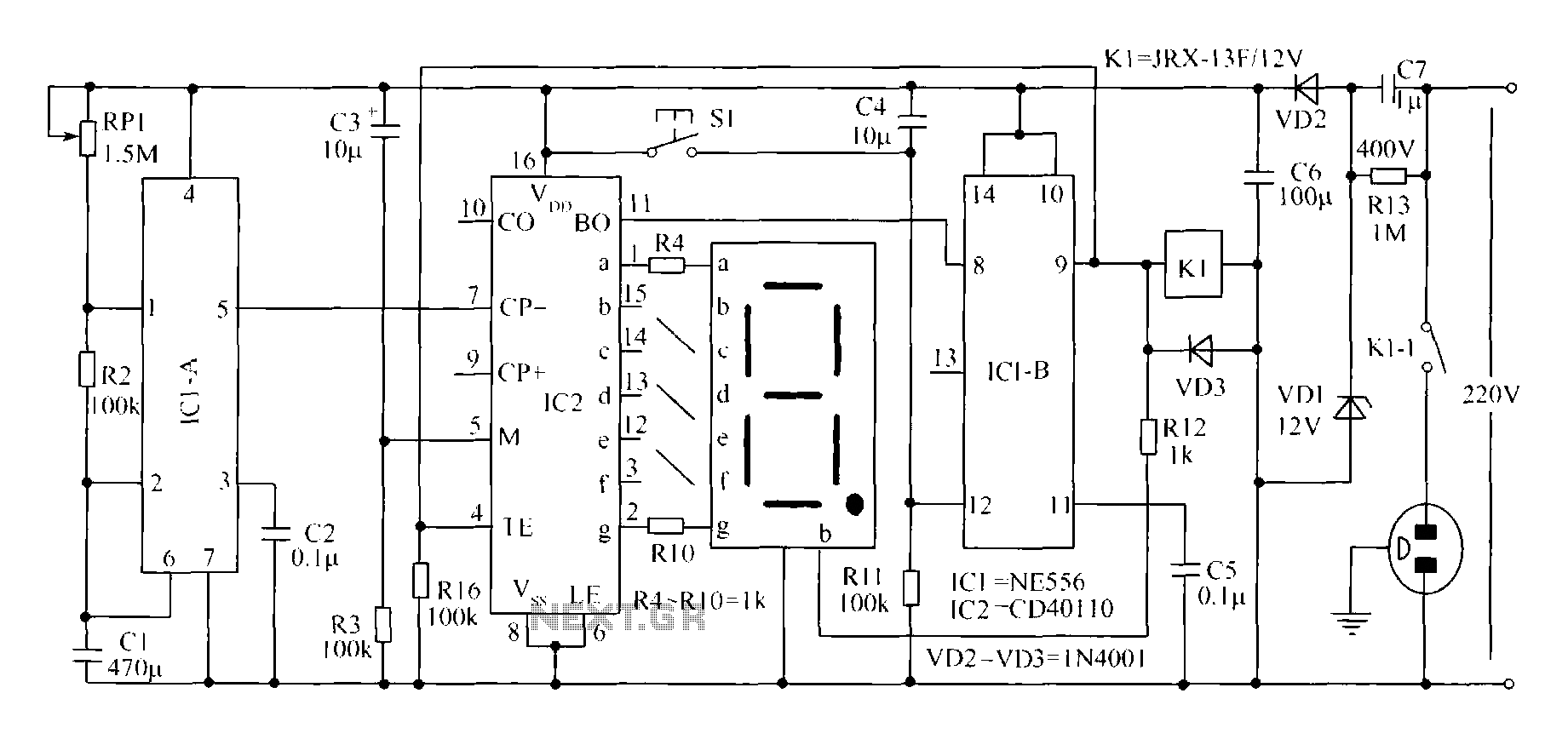

This Time Domain Reflectometer (TDR) is based on a circuit design published in the Electronics Design magazine on October 1, 1998. It is a modified version by Tomi Engdahl, which has been tested with a wide variety of cables. The reflectometer circuit is optimally powered by a 4.5V battery or three 1.5V AA batteries connected in series. The positive terminal from the battery connects to pin 14 of IC1, while pin 7 of IC1 is connected to the circuit ground. It is essential to place a 100 nF (ceramic or polypropylene) capacitor between pins 7 and 14 of IC1 to ensure stable operating voltage for the circuit. TDRs are utilized throughout all phases of a cabling system's lifecycle, including construction, maintenance, and fault detection. Historically, TDRs have been primarily accessible to large companies and high-level engineers due to their operational complexity and high cost. Any metal cable with at least two conductors can be tested using a TDR. TDRs can troubleshoot and measure various types of twisted pair and coaxial cables. They are capable of identifying both major and minor cabling issues, such as sheath faults, broken conductors, water damage, loose connectors, crimps, cuts, smashed cables, shorted conductors, system components, and numerous other fault conditions. The TDR can pinpoint the type of problem and its location along the cable. It operates on the same principle as radar; when a pulse reaches the end of the cable or encounters a fault, some or all of the pulse energy is reflected back to the instrument. Any change in impedance within the cable causes some energy to reflect back towards the TDR, which is subsequently displayed. The degree of impedance change determines the amplitude of the reflection. The TDR measures the time taken for the signal to travel down the cable, detect the problem, and return. The reflected signal is then displayed as information on a waveform monitor. This circuit is designed to be used in conjunction with a standard oscilloscope, where the circuit serves as the signal source and the oscilloscope functions as the waveform monitor. The connection diagram illustrates the setup.

The Time Domain Reflectometer (TDR) circuit operates by sending a pulse signal through a cable and analyzing the reflected signals to detect faults. The essential components of the circuit include an integrated circuit (IC), a power supply, and the necessary passive components such as resistors and capacitors to ensure proper signal integrity and stability. The IC, typically a signal generator, is responsible for producing the pulse that travels down the cable.

The circuit configuration should include a series of resistors to limit current and protect the IC from potential overcurrent situations. Additionally, the 100 nF capacitor serves a dual purpose: it helps filter out noise and ensures that the voltage remains stable during operation. The TDR's waveform display can be connected to an oscilloscope, allowing for real-time monitoring of the signal reflections. The oscilloscope's settings should be adjusted to capture the time domain signal, providing a visual representation of the cable's condition.

To enhance the functionality of the TDR, it is important to calibrate the device according to the specific cable types being tested. This calibration may involve adjusting the pulse width, amplitude, and oscilloscope settings to optimize the detection of various fault conditions. The TDR is capable of measuring cable length and determining the distance to faults based on the time it takes for the reflected pulse to return.

In summary, the TDR circuit described is a valuable tool for diagnosing cable issues, providing insights into the integrity of the cabling system, and enabling efficient maintenance and troubleshooting processes. With the appropriate setup and calibration, this TDR can serve both professional engineers and hobbyists in effectively managing cabling systems.This Time Domain Reflectometer (TDR) based on circuit idea published in Electronics Design October 1, 1998 magazine. Time Domain Reflectometer modified version by Tomi Engdahl which you see in this document. The circuit has been tested with wide variety of cables. This reflectometer circuit is best powered with 4. 5V battery or three 1. 5V AA batter ies connected in series. The + from battery goes to IC1 pin 14. The pin 7 of IC1 is connected to circuit ground which is connected to circuit ground. Remember to put a 100 nF (ceramic or polypropylene) capacitor between IC1 pins 7 and 14 to guarantee stable operating voltage for the circuit. TDRs are used in all phases of a cabling system`s life, from construction to maintenance and to fault finding.

Historically, the TDR has been reserved for only large companies and high level engineers. This was due to the complexity of operation and high cost of the instruments. If a cable is metal and it has at least two conductors, it can be tested by a TDR. TDRs will troubleshoot and measure all types of twisted pair and coaxial cables. TDRs can locate major or minor cabling problems including; sheath faults, broken conductors, water damage, loose connectors, crimps, cuts, smashed cables, shorted conductors, system components, and a variety of other fault conditions. TDR can be used to locate the problem type and in which place along the calbe the fault is. The TDR works on the same principle as radar. When that pulse reaches the end of the cable, or a fault along the cable, part or all of the pulse energy is reflected back to the instrument.

Any impedance change in cable will cause some energy to reflect back toward the TDR and will be displayed. How much the impedance changes determines the amplitude of the reflection. The TDR measures the time it takes for the signal to travel down the cable, see the problem, and reflect back.

The TDR then displays the reflected signal as information on waveform display. This circuit in this article is made to be used with a normal oscilloscope. The circuit which you build is used as the signal source and the oscilloscope is used as a waveform monitor. Connection diagram: 🔗 External reference

The Time Domain Reflectometer (TDR) circuit operates by sending a pulse signal through a cable and analyzing the reflected signals to detect faults. The essential components of the circuit include an integrated circuit (IC), a power supply, and the necessary passive components such as resistors and capacitors to ensure proper signal integrity and stability. The IC, typically a signal generator, is responsible for producing the pulse that travels down the cable.

The circuit configuration should include a series of resistors to limit current and protect the IC from potential overcurrent situations. Additionally, the 100 nF capacitor serves a dual purpose: it helps filter out noise and ensures that the voltage remains stable during operation. The TDR's waveform display can be connected to an oscilloscope, allowing for real-time monitoring of the signal reflections. The oscilloscope's settings should be adjusted to capture the time domain signal, providing a visual representation of the cable's condition.

To enhance the functionality of the TDR, it is important to calibrate the device according to the specific cable types being tested. This calibration may involve adjusting the pulse width, amplitude, and oscilloscope settings to optimize the detection of various fault conditions. The TDR is capable of measuring cable length and determining the distance to faults based on the time it takes for the reflected pulse to return.

In summary, the TDR circuit described is a valuable tool for diagnosing cable issues, providing insights into the integrity of the cabling system, and enabling efficient maintenance and troubleshooting processes. With the appropriate setup and calibration, this TDR can serve both professional engineers and hobbyists in effectively managing cabling systems.This Time Domain Reflectometer (TDR) based on circuit idea published in Electronics Design October 1, 1998 magazine. Time Domain Reflectometer modified version by Tomi Engdahl which you see in this document. The circuit has been tested with wide variety of cables. This reflectometer circuit is best powered with 4. 5V battery or three 1. 5V AA batter ies connected in series. The + from battery goes to IC1 pin 14. The pin 7 of IC1 is connected to circuit ground which is connected to circuit ground. Remember to put a 100 nF (ceramic or polypropylene) capacitor between IC1 pins 7 and 14 to guarantee stable operating voltage for the circuit. TDRs are used in all phases of a cabling system`s life, from construction to maintenance and to fault finding.

Historically, the TDR has been reserved for only large companies and high level engineers. This was due to the complexity of operation and high cost of the instruments. If a cable is metal and it has at least two conductors, it can be tested by a TDR. TDRs will troubleshoot and measure all types of twisted pair and coaxial cables. TDRs can locate major or minor cabling problems including; sheath faults, broken conductors, water damage, loose connectors, crimps, cuts, smashed cables, shorted conductors, system components, and a variety of other fault conditions. TDR can be used to locate the problem type and in which place along the calbe the fault is. The TDR works on the same principle as radar. When that pulse reaches the end of the cable, or a fault along the cable, part or all of the pulse energy is reflected back to the instrument.

Any impedance change in cable will cause some energy to reflect back toward the TDR and will be displayed. How much the impedance changes determines the amplitude of the reflection. The TDR measures the time it takes for the signal to travel down the cable, see the problem, and reflect back.

The TDR then displays the reflected signal as information on waveform display. This circuit in this article is made to be used with a normal oscilloscope. The circuit which you build is used as the signal source and the oscilloscope is used as a waveform monitor. Connection diagram: 🔗 External reference