Universal motor speed control

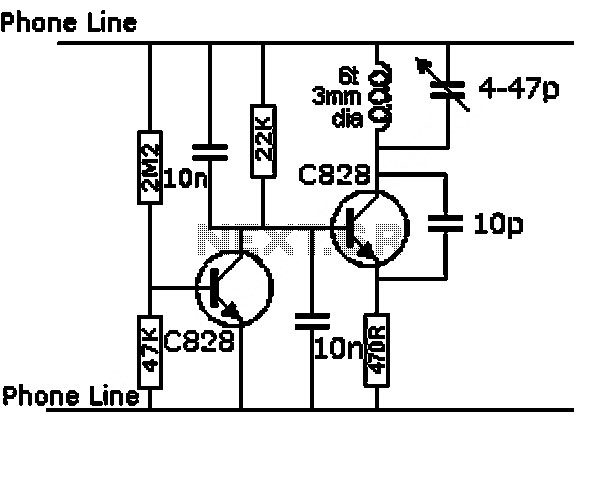

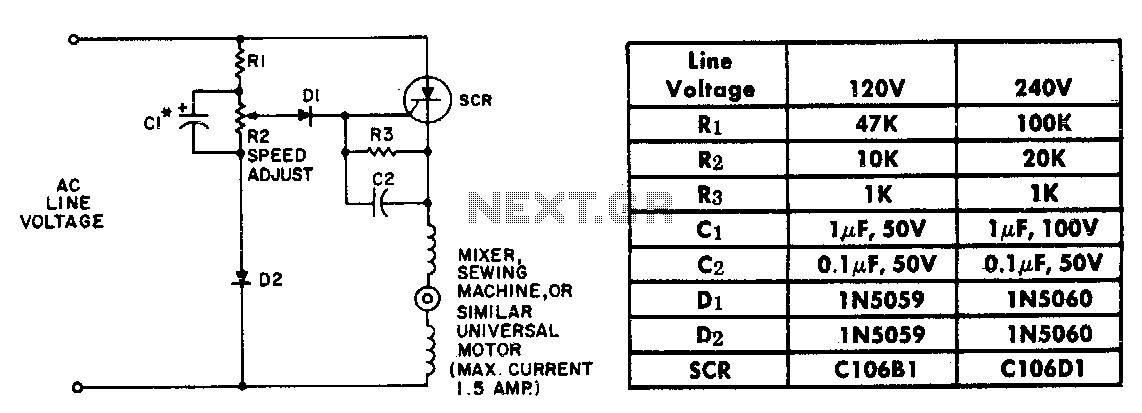

The resistor-capacitor network R1-R2-C1 generates a ramp-type reference voltage that is superimposed on an adjustable DC voltage controlled by the speed-setting potentiometer R2. This reference voltage, available at the wiper of R2, is compared against the residual counter electromotive force (emf) of the motor via the gate of the silicon-controlled rectifier (SCR). As the motor experiences a decrease in speed due to increased loading, its counter emf diminishes, causing the reference ramp to trigger the SCR earlier within the AC cycle. Consequently, more voltage is supplied to the motor, enabling it to regain speed. The performance of the C106 SCR is notably effective due to its low trigger current requirements, which facilitate the use of a flat top reference voltage, thus enhancing feedback gain and ensuring precise speed regulation.

The described circuit employs a resistor-capacitor (RC) network consisting of resistors R1 and R2, and capacitor C1, which collectively create a ramp voltage signal. This ramp voltage is essential for modulating the control of a motor's speed, particularly in applications where load variations are common. The speed-setting potentiometer R2 plays a critical role in adjusting the amplitude of the reference voltage, allowing for fine-tuning of the motor's operational characteristics.

The interaction between the ramp voltage and the motor's counter emf is crucial for effective motor control. As the motor load increases, resulting in a reduction of counter emf, the ramp voltage triggers the SCR at an earlier point in the AC cycle. This early triggering increases the voltage applied to the motor, compensating for the drop in speed caused by the heavier load.

The choice of the C106 SCR is significant due to its low trigger current requirement, which allows the circuit to utilize a flat top reference voltage. This design choice enhances the feedback gain, providing a more stable and responsive control mechanism. The flat top reference voltage contributes to improved speed regulation, ensuring that the motor can maintain its desired speed despite fluctuations in load conditions.

In summary, the combination of the RC network, speed-setting potentiometer, and SCR provides an efficient method for controlling motor speed, with particular attention to maintaining performance under varying load conditions. The overall circuit design emphasizes reliability and precision, making it well-suited for applications requiring consistent motor operation.The resistor capacitor network R1-R2-C1 provides a ramp-type reference voltage superimposed on top of a dc voltage adjustable with the speed-setting potentiometer R2. This reference voltage appearing at the wiper of R2 is balanced against the residual counter emf of the motor through the SCR gate.

As the motor slows down due to heavy loading, its counter emf falls, and the reference ramp triggers the SCR earlier in the ac cycle More voltage is thereby applied to the motor causing it to pick up speed again. Performance with the C106 SCR is particularly good because the low trigger current requirements of this device allow use of a flat top reference voltage, which provides good feedback gain and close speed regulation.

The described circuit employs a resistor-capacitor (RC) network consisting of resistors R1 and R2, and capacitor C1, which collectively create a ramp voltage signal. This ramp voltage is essential for modulating the control of a motor's speed, particularly in applications where load variations are common. The speed-setting potentiometer R2 plays a critical role in adjusting the amplitude of the reference voltage, allowing for fine-tuning of the motor's operational characteristics.

The interaction between the ramp voltage and the motor's counter emf is crucial for effective motor control. As the motor load increases, resulting in a reduction of counter emf, the ramp voltage triggers the SCR at an earlier point in the AC cycle. This early triggering increases the voltage applied to the motor, compensating for the drop in speed caused by the heavier load.

The choice of the C106 SCR is significant due to its low trigger current requirement, which allows the circuit to utilize a flat top reference voltage. This design choice enhances the feedback gain, providing a more stable and responsive control mechanism. The flat top reference voltage contributes to improved speed regulation, ensuring that the motor can maintain its desired speed despite fluctuations in load conditions.

In summary, the combination of the RC network, speed-setting potentiometer, and SCR provides an efficient method for controlling motor speed, with particular attention to maintaining performance under varying load conditions. The overall circuit design emphasizes reliability and precision, making it well-suited for applications requiring consistent motor operation.The resistor capacitor network R1-R2-C1 provides a ramp-type reference voltage superimposed on top of a dc voltage adjustable with the speed-setting potentiometer R2. This reference voltage appearing at the wiper of R2 is balanced against the residual counter emf of the motor through the SCR gate.

As the motor slows down due to heavy loading, its counter emf falls, and the reference ramp triggers the SCR earlier in the ac cycle More voltage is thereby applied to the motor causing it to pick up speed again. Performance with the C106 SCR is particularly good because the low trigger current requirements of this device allow use of a flat top reference voltage, which provides good feedback gain and close speed regulation.