rolling shutter motor control circuit

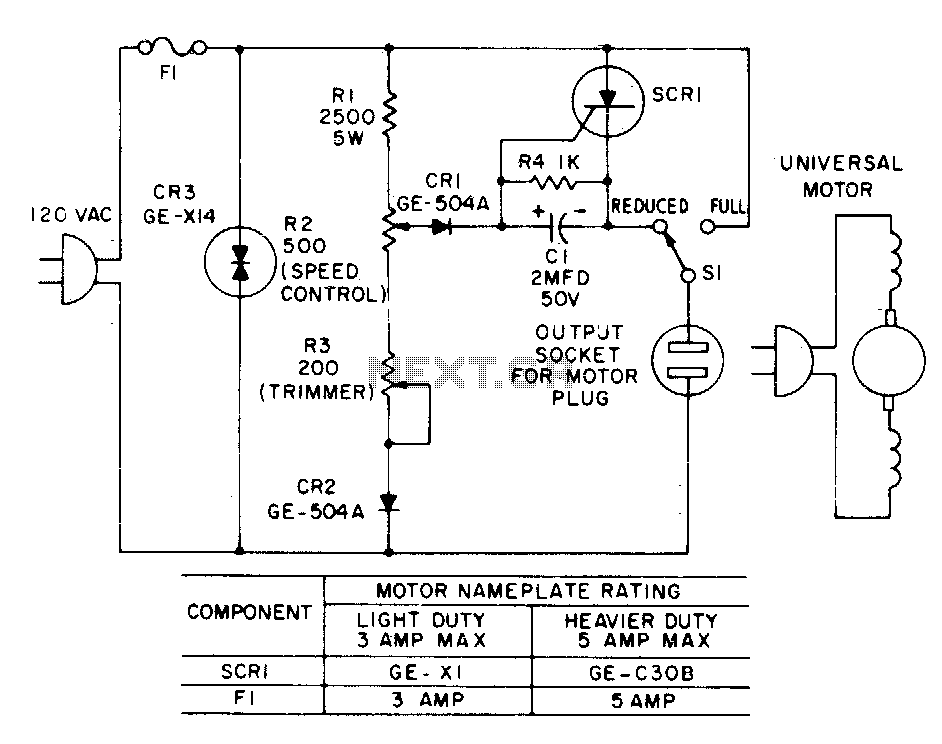

This circuit is designed for an electrically operated rolling shutter, typically featuring a standard control panel with a three-position switch: up, down, and stop. To automate the opening and closing with a time-controlled switch, additional wiring connections are required. The controls are illustrated in the schematic labeled "Normal Situation." In the schematic titled "New Situation," the automation of the shutter using a timer is depicted. To accurately determine the schematic of the control circuit, it is necessary to open the control box and utilize an ohmmeter, along with pencil and paper, to trace and draw the circuit. It is essential to ensure that the power is turned off before proceeding. A 230-V relay, with both the contacts and coil rated for 230 VAC, should be connected to the timer. The changeover switch, which toggles between automatic and manual control, must also be rated for 230 VAC to ensure user safety. The relay and switch should preferably be housed in a plastic mains adapter enclosure with a built-in plug, which connects to the timer. It is advisable to verify that this setup will fit properly. The manual/automatic switch ensures fail-safe operation, eliminating the possibility of conflicting commands that could lead to hazardous situations, such as the shutter being raised automatically while being lowered manually at the same time.

The electrically operated rolling shutter circuit is a practical solution for automated control, enhancing convenience and functionality. The three-position switch allows for manual operation, providing flexibility in controlling the shutter's position. For automation, the integration of a timer introduces a programmable element, enabling users to set specific times for the shutter to open or close, thus optimizing energy efficiency and security.

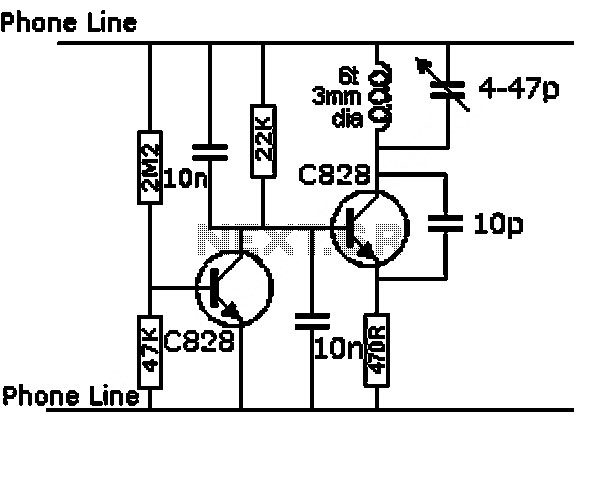

The relay plays a crucial role in this circuit, acting as an interface between the timer and the shutter motor. When the timer is activated, it energizes the relay coil, which in turn closes the relay contacts, allowing current to flow to the shutter motor. The choice of a 230-V relay ensures compatibility with standard mains voltage, while the relay's design must accommodate the current requirements of the shutter motor to prevent overheating or failure.

Safety considerations are paramount in this design. The changeover switch must be robust and rated for 230 VAC to prevent electrical hazards during operation. This switch not only allows users to toggle between automatic and manual modes but also serves as a safeguard against conflicting commands. By preventing simultaneous activation of both modes, the risk of mechanical failure or damage to the shutter system is significantly reduced.

The use of a plastic mains adapter enclosure is recommended for housing the relay and switch. This enclosure protects the components from environmental factors and accidental contact, ensuring safe operation. The built-in plug facilitates easy connection to the timer, streamlining the installation process.

In summary, the circuit design for the electrically operated rolling shutter incorporates essential components such as a three-position switch, a timer, a 230-V relay, and a safety-rated changeover switch. This configuration not only enhances automation but also prioritizes user safety and operational reliability. Proper installation and adherence to electrical standards will ensure the effective performance of the rolling shutter system.This is a circuit for an electrically operated rolling shutter usually has a standard control panel with a three-position switch: up, down and stop. If you would like to automate the opening and closing with a time controlled switch, a few additional wires will have to be connected.

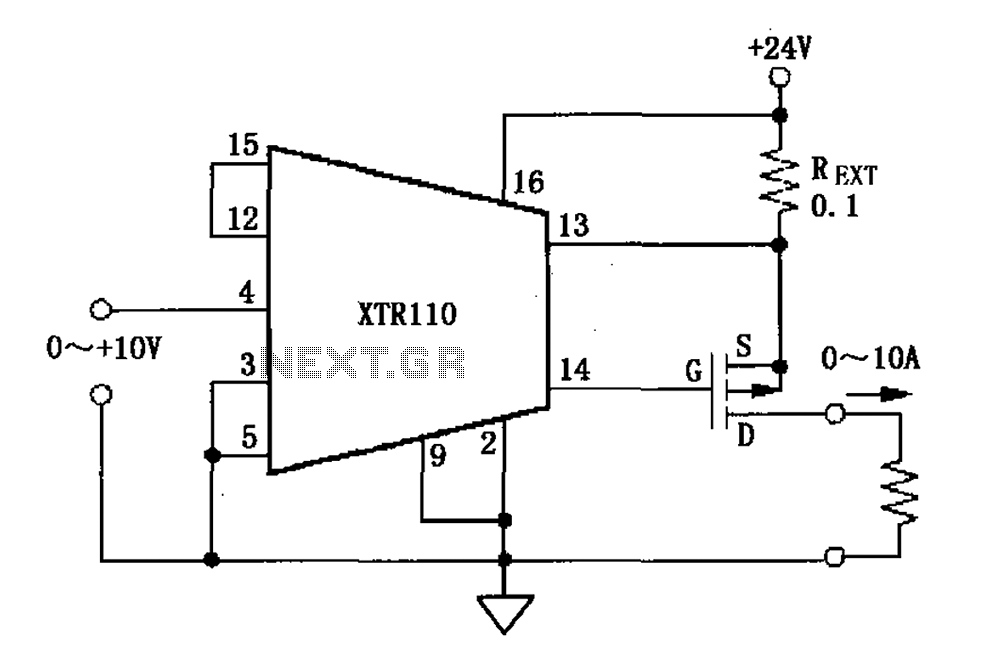

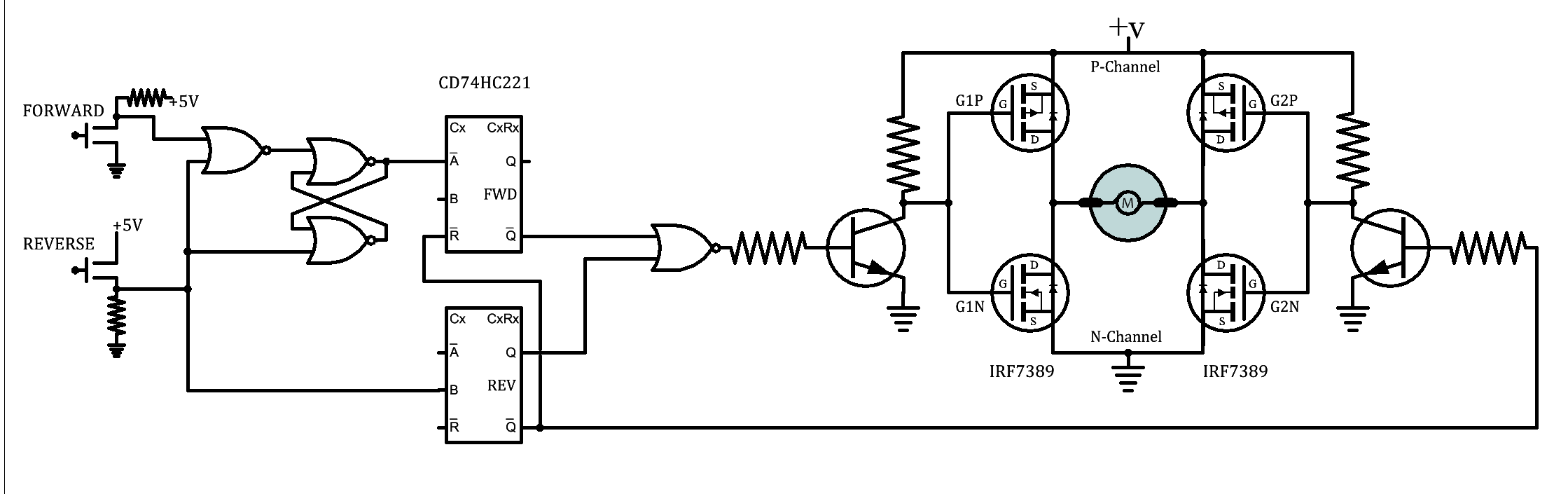

Typically, the controls are implemented as indicated in the schem atic Normal Situation`. This is the figure of the circuit; If this is indeed the case, then you can see in New Situation` how the shutter can be automated with a timer. There is only one method to determine the actual schematic of your control circuit, and that is to open the control box and using an ohmmeter, pencil and paper to check out and draw the circuit.

Make sure you turn the power off ¬rst though! Connect a 230-V relay (with both the contacts and the coil rated 230 VAC) to the timer. The changeover switch between automatic and manual control needs to be rated 230 VAC as well and may not be a hazard for the user. The relay and switch are preferably fitted in a plastic mains adapter enclosure with built-in plug, which is plugged into the timer.

It is a good idea to check first if this will actually ¬t. Because of the manual/automatic-switch, the operation is completely fail-safe and misunderstandings are out of the question. The switch prevents the issue of conflicting commands (with disastrous consequences) when, for example, the shutter is being automatically raised and manually lowered at the same time.

🔗 External reference

The electrically operated rolling shutter circuit is a practical solution for automated control, enhancing convenience and functionality. The three-position switch allows for manual operation, providing flexibility in controlling the shutter's position. For automation, the integration of a timer introduces a programmable element, enabling users to set specific times for the shutter to open or close, thus optimizing energy efficiency and security.

The relay plays a crucial role in this circuit, acting as an interface between the timer and the shutter motor. When the timer is activated, it energizes the relay coil, which in turn closes the relay contacts, allowing current to flow to the shutter motor. The choice of a 230-V relay ensures compatibility with standard mains voltage, while the relay's design must accommodate the current requirements of the shutter motor to prevent overheating or failure.

Safety considerations are paramount in this design. The changeover switch must be robust and rated for 230 VAC to prevent electrical hazards during operation. This switch not only allows users to toggle between automatic and manual modes but also serves as a safeguard against conflicting commands. By preventing simultaneous activation of both modes, the risk of mechanical failure or damage to the shutter system is significantly reduced.

The use of a plastic mains adapter enclosure is recommended for housing the relay and switch. This enclosure protects the components from environmental factors and accidental contact, ensuring safe operation. The built-in plug facilitates easy connection to the timer, streamlining the installation process.

In summary, the circuit design for the electrically operated rolling shutter incorporates essential components such as a three-position switch, a timer, a 230-V relay, and a safety-rated changeover switch. This configuration not only enhances automation but also prioritizes user safety and operational reliability. Proper installation and adherence to electrical standards will ensure the effective performance of the rolling shutter system.This is a circuit for an electrically operated rolling shutter usually has a standard control panel with a three-position switch: up, down and stop. If you would like to automate the opening and closing with a time controlled switch, a few additional wires will have to be connected.

Typically, the controls are implemented as indicated in the schem atic Normal Situation`. This is the figure of the circuit; If this is indeed the case, then you can see in New Situation` how the shutter can be automated with a timer. There is only one method to determine the actual schematic of your control circuit, and that is to open the control box and using an ohmmeter, pencil and paper to check out and draw the circuit.

Make sure you turn the power off ¬rst though! Connect a 230-V relay (with both the contacts and the coil rated 230 VAC) to the timer. The changeover switch between automatic and manual control needs to be rated 230 VAC as well and may not be a hazard for the user. The relay and switch are preferably fitted in a plastic mains adapter enclosure with built-in plug, which is plugged into the timer.

It is a good idea to check first if this will actually ¬t. Because of the manual/automatic-switch, the operation is completely fail-safe and misunderstandings are out of the question. The switch prevents the issue of conflicting commands (with disastrous consequences) when, for example, the shutter is being automatically raised and manually lowered at the same time.

🔗 External reference