Universal wiper delay

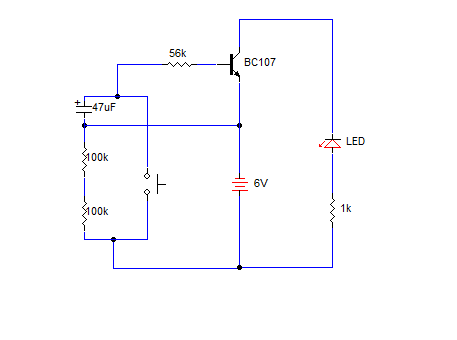

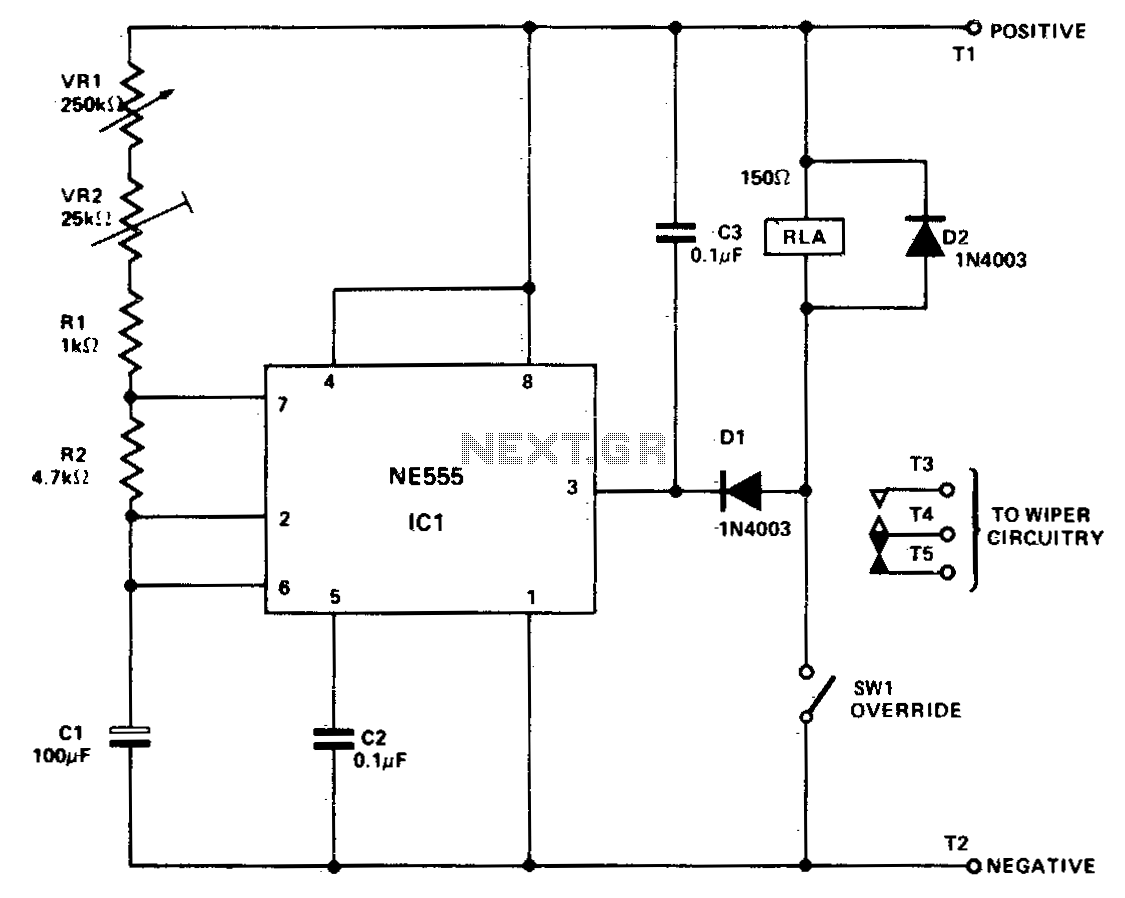

IC1 is configured in astable mode, controlling relay RLA. Capacitors C3, diodes D1 and D2 are utilized to prevent voltage spikes from the relay coil and the wiper motor from activating IC1. Variable resistor VR2 is set to provide the minimum delay time required. Variable resistor VR1 serves as the primary delay control, offering a delay range from approximately 1 second to 20 seconds. Switch SW1 acts as an override mechanism to keep relay RLA permanently activated for standard wiper operation. Additionally, the relay must possess a minimum resistance of 150 ohms and feature heavy-duty contacts. A suppression circuit may be necessary to protect IC1.

The circuit utilizes an integrated circuit (IC) configured in astable mode, which generates a continuous square wave output. This output is responsible for controlling the operation of relay RLA, which in turn activates the wiper motor. The inclusion of capacitor C3 and diodes D1 and D2 serves a critical function in the circuit by suppressing voltage spikes that may occur when the relay coil is de-energized. These spikes can potentially damage IC1 or cause unintended operation, making the suppression components essential for circuit reliability.

Variable resistor VR2 is strategically implemented to allow fine-tuning of the minimum delay time, ensuring that the circuit can accommodate various operational requirements. In contrast, variable resistor VR1 is designed to provide a broader range of delay settings, enabling the user to adjust the delay from approximately 1 second to 20 seconds. This flexibility is particularly useful for applications where different delay intervals may be needed based on specific operational conditions or user preferences.

Switch SW1 serves a dual purpose; it functions as an override switch that enables the user to maintain relay RLA in a permanently activated state. This feature is particularly beneficial for scenarios requiring continuous wiper operation, allowing for manual control over the relay without the need for the timing circuit to engage.

The relay selected for this application must meet certain specifications, specifically a minimum resistance of 150 ohms, which ensures that it can effectively handle the current without overheating or failing. Additionally, the relay should be equipped with heavy-duty contacts to withstand the electrical load and mechanical wear associated with frequent operation.

To further enhance the protection of IC1, the inclusion of a suppression circuit is advisable. This circuit can be designed to mitigate any transient voltage spikes that may arise during the operation of the relay or the wiper motor, thereby safeguarding the integrity of the integrated circuit and ensuring long-term reliability of the overall system.ICl is connected in the astable mode, driving RLA, C3, Dl, and D2 prevent spikes from the relay coil and the wiper motor from triggering ICl. VR2 is adjusted to give the minimum delay time required. VR1 is the main delay control and pro vides a range of from about 1 second to 20 seconds. SW1 is an override switch to hold RLA permanently on (for normal wiper operation) The relay should have a resistance of at least 150 ohms and have heavy duty contacts. The suppression circuit may be needed for the protection of ICl. 🔗 External reference

The circuit utilizes an integrated circuit (IC) configured in astable mode, which generates a continuous square wave output. This output is responsible for controlling the operation of relay RLA, which in turn activates the wiper motor. The inclusion of capacitor C3 and diodes D1 and D2 serves a critical function in the circuit by suppressing voltage spikes that may occur when the relay coil is de-energized. These spikes can potentially damage IC1 or cause unintended operation, making the suppression components essential for circuit reliability.

Variable resistor VR2 is strategically implemented to allow fine-tuning of the minimum delay time, ensuring that the circuit can accommodate various operational requirements. In contrast, variable resistor VR1 is designed to provide a broader range of delay settings, enabling the user to adjust the delay from approximately 1 second to 20 seconds. This flexibility is particularly useful for applications where different delay intervals may be needed based on specific operational conditions or user preferences.

Switch SW1 serves a dual purpose; it functions as an override switch that enables the user to maintain relay RLA in a permanently activated state. This feature is particularly beneficial for scenarios requiring continuous wiper operation, allowing for manual control over the relay without the need for the timing circuit to engage.

The relay selected for this application must meet certain specifications, specifically a minimum resistance of 150 ohms, which ensures that it can effectively handle the current without overheating or failing. Additionally, the relay should be equipped with heavy-duty contacts to withstand the electrical load and mechanical wear associated with frequent operation.

To further enhance the protection of IC1, the inclusion of a suppression circuit is advisable. This circuit can be designed to mitigate any transient voltage spikes that may arise during the operation of the relay or the wiper motor, thereby safeguarding the integrity of the integrated circuit and ensuring long-term reliability of the overall system.ICl is connected in the astable mode, driving RLA, C3, Dl, and D2 prevent spikes from the relay coil and the wiper motor from triggering ICl. VR2 is adjusted to give the minimum delay time required. VR1 is the main delay control and pro vides a range of from about 1 second to 20 seconds. SW1 is an override switch to hold RLA permanently on (for normal wiper operation) The relay should have a resistance of at least 150 ohms and have heavy duty contacts. The suppression circuit may be needed for the protection of ICl. 🔗 External reference