Very high current power supply

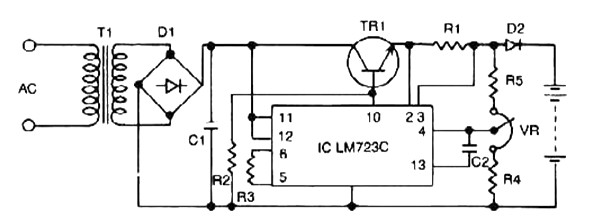

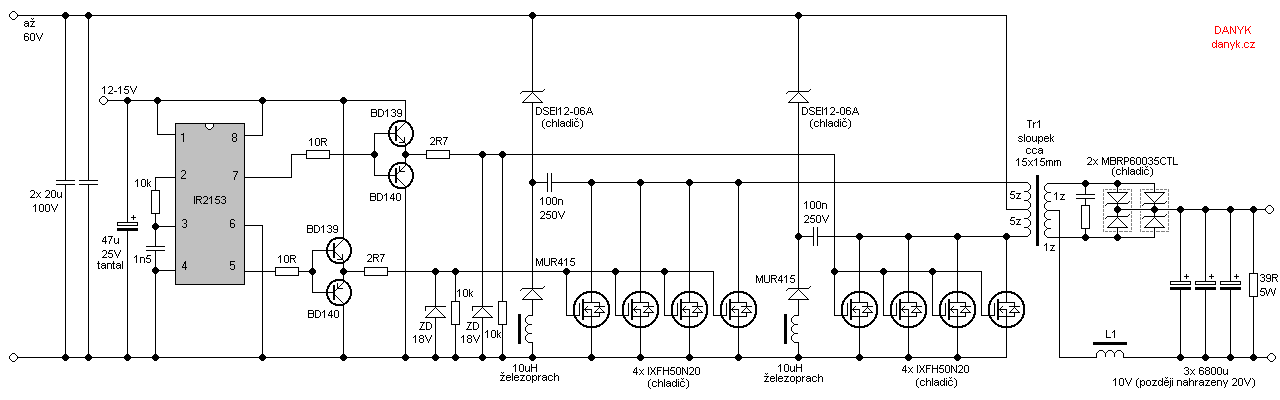

Occasionally, a low voltage power supply capable of delivering very high currents (hundreds of amperes) is required for applications such as spot welding, heating or melting metals, starting vehicle engines, or conducting various physical experiments. A decision has been made to construct such a supply. With an existing switching power supply rated at 3-60V 40A and another at 60A 56V, the intention is to build a switching inverter that converts a DC voltage of up to 60V to a lower voltage, approximately 12V, while increasing the current output. The chosen topology is a push-pull configuration utilizing a transformer with a 5:1 turns ratio. Voltage regulation and current limiting, if necessary, are managed by the input voltage source. This switching inverter effectively reduces the input voltage by a ratio close to 5:1, accounting for losses and voltage drops (such as those across diodes, MOSFETs, winding, and conductor resistances), resulting in a practical ratio of up to 6:1. Consequently, the inverter also amplifies the allowable current; for a 40A input source, an output of approximately 200-240A can be achieved. The maximum output voltage of this high current switching inverter is around 10-12V. The schematic diagram of the described switching inverter features a transformer (Tr1) with primary windings of 5+5 turns and secondary windings of 1+1 turn. Switching is accomplished using 4 + 4 MOSFETs, specifically the IXFH50N20 model (50A, 200V, 45mR, Cg = 4400pF). Alternative MOSFETs with a Uds rating of 200V (or 150V) and low on-resistance can also be employed. The gate charge should ideally be minimal for improved switching speed. Secondary rectification is performed using two double Schottky diodes, MBRP60035CTL (600A, 35V). The ferrite transformer Tr1 has a cross-sectional area of approximately 15 x 15 mm. The inductor (L1) consists of five iron powder rings threaded onto wires. Inductance, heat sinks, and other components were salvaged from an old 56V/5V inverter designed for high current applications in information technology. The original snubber circuits on the power board were retained, while the gates were disconnected from the original circuit and connected to a custom control circuit utilizing the IR2153 integrated circuit. Due to the high gate capacitance (4x 4.4nF), a power amplifier made from a pair of NPN/PNP transistors (BD139 and BD140) was necessary. The IR2153 control circuit could be substituted with other PWM-capable control circuits, such as the SG3525, to achieve a regulated output. The design allows for potential modifications to the input voltage (by using different MOSFETs, primary turns, etc.) and could even be adapted to operate directly from rectified mains voltage. This switching supply topology ensures galvanic isolation. Caution is advised, as MOSFETs are subjected to double the input voltage (at 60V, they experience 120V, and in the case of rectified 230V AC mains, this could rise to 650V). The operating frequency is approximately 40kHz. For short-term applications, such as vehicle engine starting or spot welding, the cooling and winding specifications are not as critical. However, continuous operation necessitates effective cooling solutions. The highest power losses occur at the output diodes, where the Schottky voltage drop is approximately 0.5V; thus, at a current of 240A, the resulting loss can reach 120W.

This switching inverter design is particularly useful in applications requiring high current output while maintaining low voltage levels. The push-pull topology is advantageous for its efficiency and simplicity in implementation. The transformer plays a crucial role in maintaining the desired voltage transformation while allowing for significant current amplification. The selected MOSFETs must be capable of handling the high voltage and current demands, with careful attention to their on-resistance to minimize heat generation during operation. The use of Schottky diodes for rectification is beneficial due to their low forward voltage drop, which contributes to overall efficiency.

In terms of thermal management, adequate heat sinks and cooling mechanisms must be incorporated to ensure reliable operation, particularly during continuous use. The design's ability to operate at a frequency of 40kHz allows for compact transformer designs and reduced component sizes, which is advantageous for applications with space constraints. The flexibility to modify input parameters and adapt the design for different operational scenarios enhances its utility across a range of high current applications. Overall, this schematic represents a robust solution for generating high current low voltage power supplies in various industrial and experimental settings.Sometimes you need a low voltage power supply of very high currents (hundreds of amperes) - whether for spot welding, heating or melting metals, starting the vehicle engine, or other physical experiments. Such a supply I have now decided to build. Given that I already have a switching power supply 3-60V 40A and 60A 56V power supply, so I desided t

o build a switching inverter that which will change the DC voltage of up to 60V to a smaller voltage to approximately 12V at a higher current. I chose the topology of push-pull that uses a transformer with 5:1 ratio. Voltage regulation (if necessary) and current limit are provided by a source of input voltage. This switching inverter reduces the input voltage of approximately 5:1 ratio minus the lossed and voltage drops (diodes, MOSFETs, winding and conductors resistance), in practice it is up to 6:1.

In almost the same rate, thw inverted increases the allowable current. For 40A input source you can get about 200 - 240A. The highest output voltage of this high current switching inverter is about 10-12V. The schematic diagram of the described switching inverter is shown below. Transformer Tr1 has primaries 5+5 turns and secondaries 1+1 turn. Switching is provided by 4 + 4 MOSFETs. I used IXFH50N20 type (50A, 200V, 45mR, Cg = 4400pF). You can use any voltage MOSFETs with Uds 200V (150V) and the least conductive resistance. The speed and smaller capacity (charge) of gate are also not bad. Secondary rectification is provided by two double Schottky diodes MBRP60035CTL (600A, 35V). Ferrite transformer Tr1 has the cross section about 15 x 15 mm. Inductor L1 is formed by 5 iron powder rings threaded on wires. Inductance, radiator and some other parts I got from some old inverter 56V / 5V (hundreds of A), that was used for information technology. I used the original snubbers on the power board. I disconnected the gates from the original circuit (unusable) and hooked to my own control circuit. It uses an integrated circuit IR2153. Due to the large capacity of gates (4x 4n4), I had to use a power amplifier with a pair of NPN / PNP transistors BD139 and BD140.

However, the IR2153 circuit can be replaced by other control circuit allows pulse width modulation (PWM), for example, SG3525, to create a regulated source. It is theoretically possible to change the input voltage (other MOSFETs, primaries, etc. ) and even work directly with a rectified mains. This switching supply topology provides galvanic isolation. Warning - MOSFETs sees twice the input voltage (at 60V it is 120V and in case of rectified 230V~ mains it would be 650V).

Operating frequency is about 40kHz. In the short term use (eg as a vehicle engine starting source, spot welder) are not so great demands on the cooling, winding sizing, etc. In continuous operation, good cooling is necessary. Greatest power loss occurs at the output diodes. Schottky voltage drop is about 0. 5 V and a current for example 240A gives its loss of 120W. 🔗 External reference

This switching inverter design is particularly useful in applications requiring high current output while maintaining low voltage levels. The push-pull topology is advantageous for its efficiency and simplicity in implementation. The transformer plays a crucial role in maintaining the desired voltage transformation while allowing for significant current amplification. The selected MOSFETs must be capable of handling the high voltage and current demands, with careful attention to their on-resistance to minimize heat generation during operation. The use of Schottky diodes for rectification is beneficial due to their low forward voltage drop, which contributes to overall efficiency.

In terms of thermal management, adequate heat sinks and cooling mechanisms must be incorporated to ensure reliable operation, particularly during continuous use. The design's ability to operate at a frequency of 40kHz allows for compact transformer designs and reduced component sizes, which is advantageous for applications with space constraints. The flexibility to modify input parameters and adapt the design for different operational scenarios enhances its utility across a range of high current applications. Overall, this schematic represents a robust solution for generating high current low voltage power supplies in various industrial and experimental settings.Sometimes you need a low voltage power supply of very high currents (hundreds of amperes) - whether for spot welding, heating or melting metals, starting the vehicle engine, or other physical experiments. Such a supply I have now decided to build. Given that I already have a switching power supply 3-60V 40A and 60A 56V power supply, so I desided t

o build a switching inverter that which will change the DC voltage of up to 60V to a smaller voltage to approximately 12V at a higher current. I chose the topology of push-pull that uses a transformer with 5:1 ratio. Voltage regulation (if necessary) and current limit are provided by a source of input voltage. This switching inverter reduces the input voltage of approximately 5:1 ratio minus the lossed and voltage drops (diodes, MOSFETs, winding and conductors resistance), in practice it is up to 6:1.

In almost the same rate, thw inverted increases the allowable current. For 40A input source you can get about 200 - 240A. The highest output voltage of this high current switching inverter is about 10-12V. The schematic diagram of the described switching inverter is shown below. Transformer Tr1 has primaries 5+5 turns and secondaries 1+1 turn. Switching is provided by 4 + 4 MOSFETs. I used IXFH50N20 type (50A, 200V, 45mR, Cg = 4400pF). You can use any voltage MOSFETs with Uds 200V (150V) and the least conductive resistance. The speed and smaller capacity (charge) of gate are also not bad. Secondary rectification is provided by two double Schottky diodes MBRP60035CTL (600A, 35V). Ferrite transformer Tr1 has the cross section about 15 x 15 mm. Inductor L1 is formed by 5 iron powder rings threaded on wires. Inductance, radiator and some other parts I got from some old inverter 56V / 5V (hundreds of A), that was used for information technology. I used the original snubbers on the power board. I disconnected the gates from the original circuit (unusable) and hooked to my own control circuit. It uses an integrated circuit IR2153. Due to the large capacity of gates (4x 4n4), I had to use a power amplifier with a pair of NPN / PNP transistors BD139 and BD140.

However, the IR2153 circuit can be replaced by other control circuit allows pulse width modulation (PWM), for example, SG3525, to create a regulated source. It is theoretically possible to change the input voltage (other MOSFETs, primaries, etc. ) and even work directly with a rectified mains. This switching supply topology provides galvanic isolation. Warning - MOSFETs sees twice the input voltage (at 60V it is 120V and in case of rectified 230V~ mains it would be 650V).

Operating frequency is about 40kHz. In the short term use (eg as a vehicle engine starting source, spot welder) are not so great demands on the cooling, winding sizing, etc. In continuous operation, good cooling is necessary. Greatest power loss occurs at the output diodes. Schottky voltage drop is about 0. 5 V and a current for example 240A gives its loss of 120W. 🔗 External reference