Wiper Speed Control

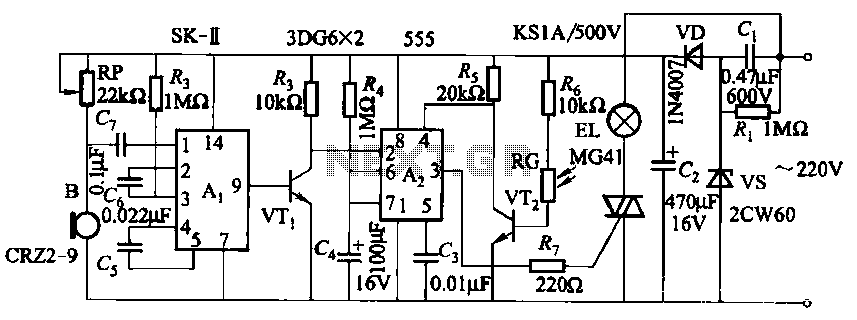

Wiper Speed Control. A continuously operating wiper in a vehicle can be bothersome, particularly during light rain. The circuit described here allows for the adjustment of the wiper's sweeping rate, ranging from once per second to once every ten seconds.

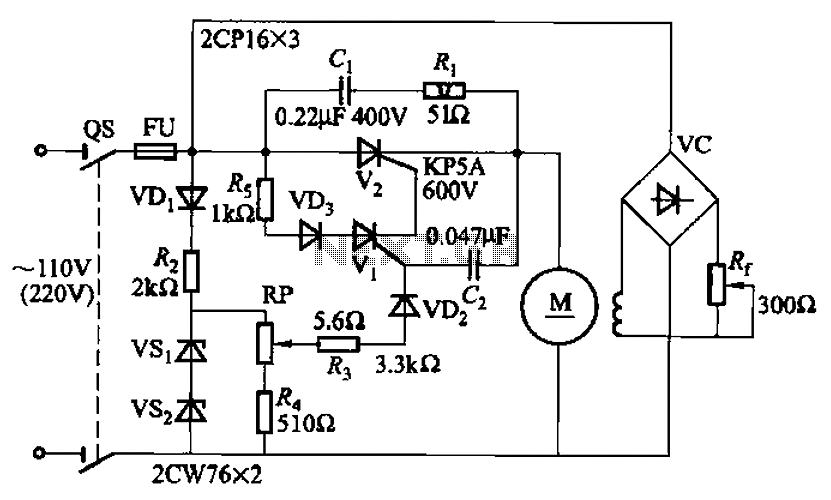

The wiper speed control circuit typically employs a variable resistor or potentiometer to adjust the timing of the wiper motor operation. This circuit can be implemented using a simple timer IC, such as the NE555, configured in astable mode, to generate a square wave output that drives the wiper motor.

The key components of the circuit include the NE555 timer, a motor driver (such as a transistor or a relay), a potentiometer for speed adjustment, and capacitors for timing control. The potentiometer alters the resistance in the timing circuit, thereby changing the duty cycle of the output signal. This adjustment directly influences how often the wipers sweep across the windshield.

In the astable configuration, the NE555 timer continuously oscillates between its high and low states, which can be set to correspond to the desired wiper speed. The output from the NE555 can be fed into a transistor, which acts as a switch to control the wiper motor. The motor will then operate at the speed determined by the timing circuit, allowing the driver to set a comfortable wiper frequency based on the current weather conditions.

Additionally, diodes can be incorporated to protect the circuit from back EMF generated by the motor, ensuring the longevity and reliability of the wiper speed control system. This setup enhances the driving experience by providing customizable wiper functionality, adapting to varying levels of precipitation.Wiper Speed Control. A continuously working wiper in a car may prove to be a nuisance, especially when it is not raining heavily. By using the circuit described here one can vary sweeping rate of the wiper from once a second to once in ten seconds

🔗 External reference

The wiper speed control circuit typically employs a variable resistor or potentiometer to adjust the timing of the wiper motor operation. This circuit can be implemented using a simple timer IC, such as the NE555, configured in astable mode, to generate a square wave output that drives the wiper motor.

The key components of the circuit include the NE555 timer, a motor driver (such as a transistor or a relay), a potentiometer for speed adjustment, and capacitors for timing control. The potentiometer alters the resistance in the timing circuit, thereby changing the duty cycle of the output signal. This adjustment directly influences how often the wipers sweep across the windshield.

In the astable configuration, the NE555 timer continuously oscillates between its high and low states, which can be set to correspond to the desired wiper speed. The output from the NE555 can be fed into a transistor, which acts as a switch to control the wiper motor. The motor will then operate at the speed determined by the timing circuit, allowing the driver to set a comfortable wiper frequency based on the current weather conditions.

Additionally, diodes can be incorporated to protect the circuit from back EMF generated by the motor, ensuring the longevity and reliability of the wiper speed control system. This setup enhances the driving experience by providing customizable wiper functionality, adapting to varying levels of precipitation.Wiper Speed Control. A continuously working wiper in a car may prove to be a nuisance, especially when it is not raining heavily. By using the circuit described here one can vary sweeping rate of the wiper from once a second to once in ten seconds

🔗 External reference