One simple charging circuit b porcelain

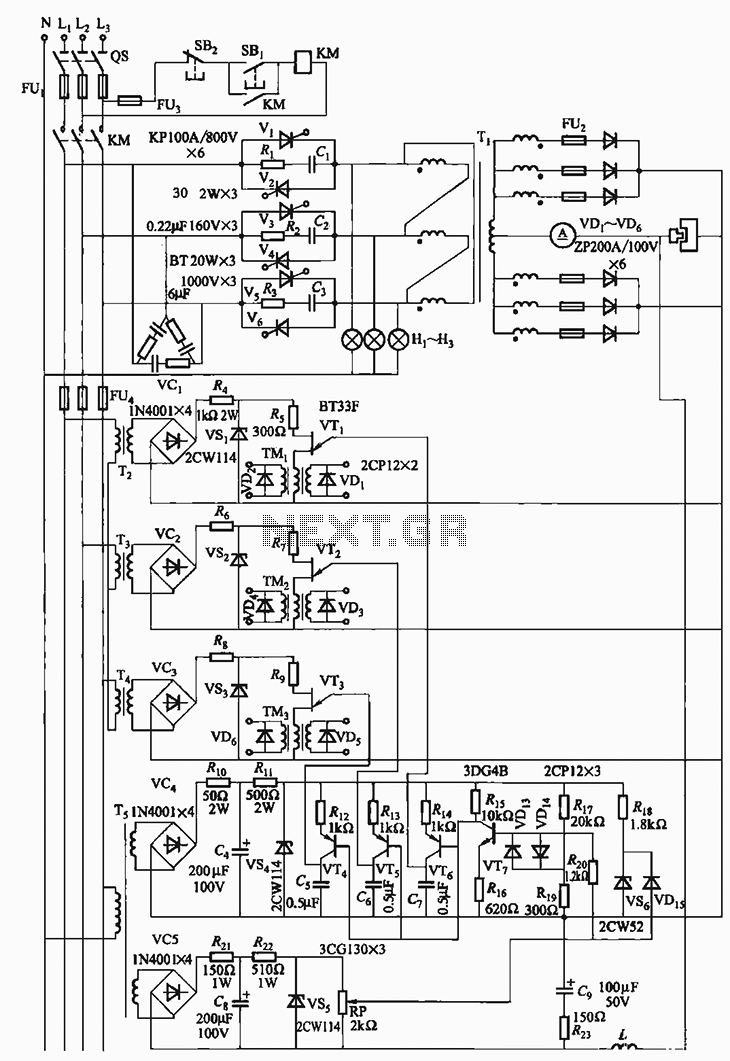

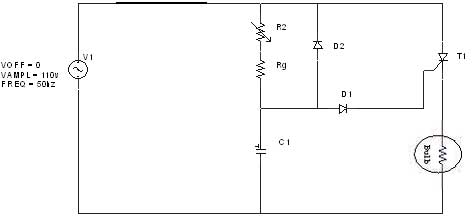

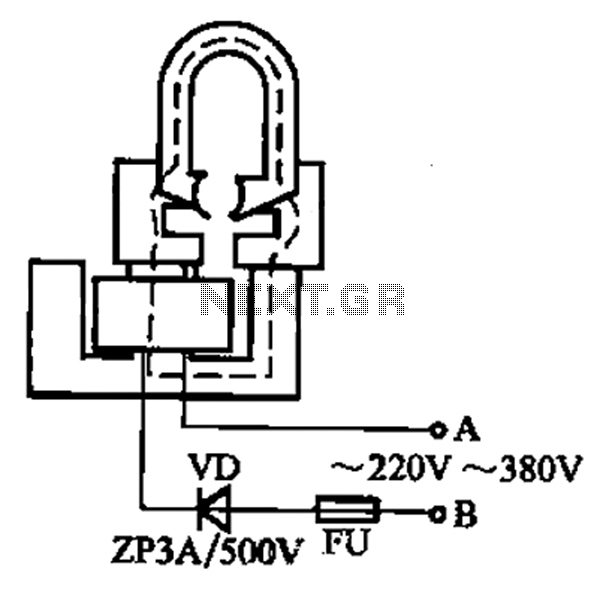

After a slight loss of field strength, magnets can be re-magnetized using a simple homemade porcelain filler. Locate scrap materials such as switches and contacts, as well as other models like CJ10-60 ~ 15. The circuit can operate at 0A with either 220V or 380V. The term "armature" should be excluded; only the Yamagata core is relevant. In the coil circuit, include a fuse and a diode string that facilitate the charging of the porcelain, as demonstrated in the 10-42 fold. Figure (a) illustrates the process for strip magnet magnetization, while Figure (b) shows the application for soft iron using a U-shaped magnet. During magnetization, connect both ends to a 220V (nominal coil voltage) or 380V (rated coil voltage of 380V) AC power supply, ensuring safety precautions are observed. Sparks may occur upon contact; only a brief touch is required, typically one or two times. After a ten-second interval following the initial touch, repeat the process one or two more times to complete the magnetization. Allow the assembly to stand for several hours before removal to observe the effects.

In the context of re-magnetizing magnets using a homemade porcelain filler, it is essential to understand the components involved and the operational procedures. The Yamagata core serves as the primary magnetic material, which, when subjected to the appropriate voltage, can regain its magnetic properties. The circuit design should incorporate a fuse to protect against overcurrent conditions and a diode string to rectify the AC voltage, ensuring that the porcelain filler receives the necessary charge without damaging the circuit.

The magnetization process can be visually represented in two figures: Figure (a) for strip magnet magnetization and Figure (b) for soft iron magnetization using a U-shaped magnet. The connection to the AC power supply should be made with caution, as the high voltage can produce sparks. This indicates that the circuit is energized and functioning correctly. The specified waiting period of ten seconds is crucial, as it allows the magnetic field to stabilize before the next application of voltage.

After the magnetization process, the assembly should be left undisturbed for several hours. This resting period is vital for the magnetic properties to settle, enhancing the effectiveness of the re-magnetization. The final product will exhibit improved magnetic strength, enabling it to perform its intended function more effectively. Proper handling and safety measures during this process are paramount to prevent accidents and ensure successful re-magnetization.After some small loss of field magnets can be re-magnetized porcelain filled with homemade simple. Find a scrap of exchanges and contacts, and other models such as CJ10-60 ~ 15 0A (220V or 380V can), remove the word armature, only Yamagata core. In the coil circuit fuse and a diode string, they formed a charge porcelain, as 10-42 fold shown. Figure (a) applies to a strip magnet magnetization, FIG. (B) applies to soft iron by setting the U-shaped magnet. When magnetizing, with A, B both ends to touch 220V (nominal coil voltage of 220V) or 380V (rated coil voltage of 180V at) AC power supply (pay attention to safety), there are sparks when touched, just touch 1, 2 times. Wait ten seconds after the punch, then touch 1,2 times, magnetization ends. Then allowed to stand for several hours and then remove (this effect).

In the context of re-magnetizing magnets using a homemade porcelain filler, it is essential to understand the components involved and the operational procedures. The Yamagata core serves as the primary magnetic material, which, when subjected to the appropriate voltage, can regain its magnetic properties. The circuit design should incorporate a fuse to protect against overcurrent conditions and a diode string to rectify the AC voltage, ensuring that the porcelain filler receives the necessary charge without damaging the circuit.

The magnetization process can be visually represented in two figures: Figure (a) for strip magnet magnetization and Figure (b) for soft iron magnetization using a U-shaped magnet. The connection to the AC power supply should be made with caution, as the high voltage can produce sparks. This indicates that the circuit is energized and functioning correctly. The specified waiting period of ten seconds is crucial, as it allows the magnetic field to stabilize before the next application of voltage.

After the magnetization process, the assembly should be left undisturbed for several hours. This resting period is vital for the magnetic properties to settle, enhancing the effectiveness of the re-magnetization. The final product will exhibit improved magnetic strength, enabling it to perform its intended function more effectively. Proper handling and safety measures during this process are paramount to prevent accidents and ensure successful re-magnetization.After some small loss of field magnets can be re-magnetized porcelain filled with homemade simple. Find a scrap of exchanges and contacts, and other models such as CJ10-60 ~ 15 0A (220V or 380V can), remove the word armature, only Yamagata core. In the coil circuit fuse and a diode string, they formed a charge porcelain, as 10-42 fold shown. Figure (a) applies to a strip magnet magnetization, FIG. (B) applies to soft iron by setting the U-shaped magnet. When magnetizing, with A, B both ends to touch 220V (nominal coil voltage of 220V) or 380V (rated coil voltage of 180V at) AC power supply (pay attention to safety), there are sparks when touched, just touch 1, 2 times. Wait ten seconds after the punch, then touch 1,2 times, magnetization ends. Then allowed to stand for several hours and then remove (this effect).

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713