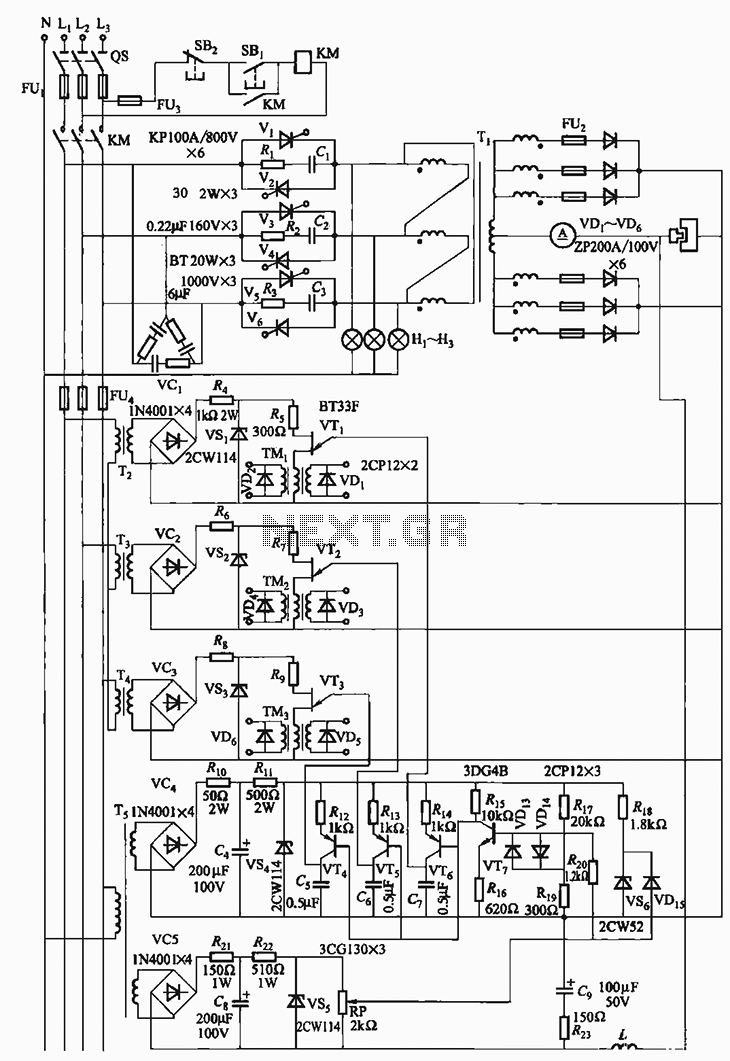

300A-18V three-phase thyristor power regulator circuit for electrolysis

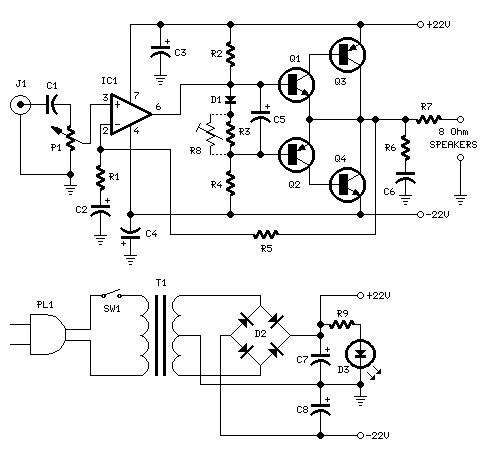

The 300A-18V three-phase thyristor power regulator circuit is designed for electrolysis applications. It can output a direct current of 3000A at an adjustable voltage of 18V, providing a power supply solution for various processing needs. The circuit comprises a main circuit, a trigger circuit, a synchronous power component, DC power, and a voltage negative feedback mechanism. Additionally, it includes a circuit protection feature. The voltage negative feedback is derived from the cell (specifically from the rectifier output), with a reactor L superimposed on a specified voltage adjusted via the potentiometer RP. The voltage differential negative feedback is managed by components R23 and C9, which function as a regulator with automatic voltage negative feedback. Due to the narrow pulse output from the single-junction transistor relaxation oscillator, a reliable short pulse is generated to trigger the transformer Ti, which operates in parallel with a 150W lamp load across three phases.

The 300A-18V three-phase thyristor power regulator circuit is a sophisticated electronic system tailored for high-current electrolysis processes. The design emphasizes efficiency and stability, utilizing thyristors to control the output voltage and current levels. The circuit architecture consists of several critical components: the main power circuit handles the high current, while the trigger circuit activates the thyristors at precise intervals to regulate the power delivered to the load.

The voltage negative feedback system is a crucial feature that enhances stability and performance. By sampling the output voltage from the rectifier, the feedback loop adjusts the operation of the thyristors to maintain the desired output voltage despite variations in load conditions. The use of a reactor L introduces a controlled inductance into the circuit, which helps smooth out fluctuations and provides a stable operating environment. The potentiometer RP allows for fine-tuning of the voltage output, enabling operators to adjust the system to meet specific processing requirements.

Components R23 and C9 form a differential feedback network that further stabilizes the output by responding to changes in load and voltage. This automatic voltage regulation ensures that the system can adapt to varying operational demands without manual intervention, significantly improving reliability.

The integration of a single-junction transistor relaxation oscillator is an innovative approach to generating the necessary trigger pulses for the thyristors. The narrow pulse width produced by this oscillator is essential for the accurate timing of the thyristor firing, which is critical for maintaining the desired output characteristics. The design also incorporates a transformer Ti that is responsible for distributing power across the three phases, effectively balancing the load and enhancing overall system performance.

Finally, the inclusion of a 150W lamp load serves as a practical demonstration of the circuit's capabilities, allowing for real-time testing and validation of the system's performance under operational conditions. This comprehensive design ensures that the 300A-18V thyristor power regulator circuit is not only effective for electrolysis applications but also adaptable for various industrial power supply needs.300A-18V three-phase thyristor power regulator circuit electrolysis It can output DC 3000A, 18V (adjustable), power supply solution processing. Circuit from the main circuit, trigger circuit, part of the synchronous power, DC power, voltage negative feedback

circuit and protection circuit. Voltage negative feedback voltage is removed from the cell (ie, the rectifier output), the reactor L superimposed on a given voltage (by the potentiometer RP to the drawing). Voltage differential negative feedback by the R23 and C9. It plays the role of regulator with automatic voltage negative feedback. Since the single-junction transistor relaxation oscillator output pulse is narrow, in order to make reliable short pulse to trigger the transformer Ti of three phases in parallel a 150W lamp load.

The 300A-18V three-phase thyristor power regulator circuit is a sophisticated electronic system tailored for high-current electrolysis processes. The design emphasizes efficiency and stability, utilizing thyristors to control the output voltage and current levels. The circuit architecture consists of several critical components: the main power circuit handles the high current, while the trigger circuit activates the thyristors at precise intervals to regulate the power delivered to the load.

The voltage negative feedback system is a crucial feature that enhances stability and performance. By sampling the output voltage from the rectifier, the feedback loop adjusts the operation of the thyristors to maintain the desired output voltage despite variations in load conditions. The use of a reactor L introduces a controlled inductance into the circuit, which helps smooth out fluctuations and provides a stable operating environment. The potentiometer RP allows for fine-tuning of the voltage output, enabling operators to adjust the system to meet specific processing requirements.

Components R23 and C9 form a differential feedback network that further stabilizes the output by responding to changes in load and voltage. This automatic voltage regulation ensures that the system can adapt to varying operational demands without manual intervention, significantly improving reliability.

The integration of a single-junction transistor relaxation oscillator is an innovative approach to generating the necessary trigger pulses for the thyristors. The narrow pulse width produced by this oscillator is essential for the accurate timing of the thyristor firing, which is critical for maintaining the desired output characteristics. The design also incorporates a transformer Ti that is responsible for distributing power across the three phases, effectively balancing the load and enhancing overall system performance.

Finally, the inclusion of a 150W lamp load serves as a practical demonstration of the circuit's capabilities, allowing for real-time testing and validation of the system's performance under operational conditions. This comprehensive design ensures that the 300A-18V thyristor power regulator circuit is not only effective for electrolysis applications but also adaptable for various industrial power supply needs.300A-18V three-phase thyristor power regulator circuit electrolysis It can output DC 3000A, 18V (adjustable), power supply solution processing. Circuit from the main circuit, trigger circuit, part of the synchronous power, DC power, voltage negative feedback

circuit and protection circuit. Voltage negative feedback voltage is removed from the cell (ie, the rectifier output), the reactor L superimposed on a given voltage (by the potentiometer RP to the drawing). Voltage differential negative feedback by the R23 and C9. It plays the role of regulator with automatic voltage negative feedback. Since the single-junction transistor relaxation oscillator output pulse is narrow, in order to make reliable short pulse to trigger the transformer Ti of three phases in parallel a 150W lamp load.