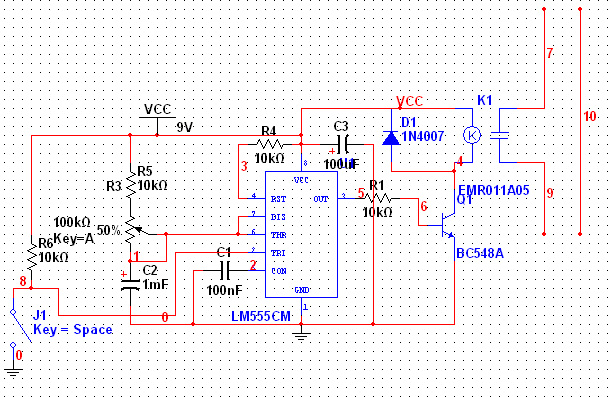

Two motor speed control circuit and the main level indicating circuit

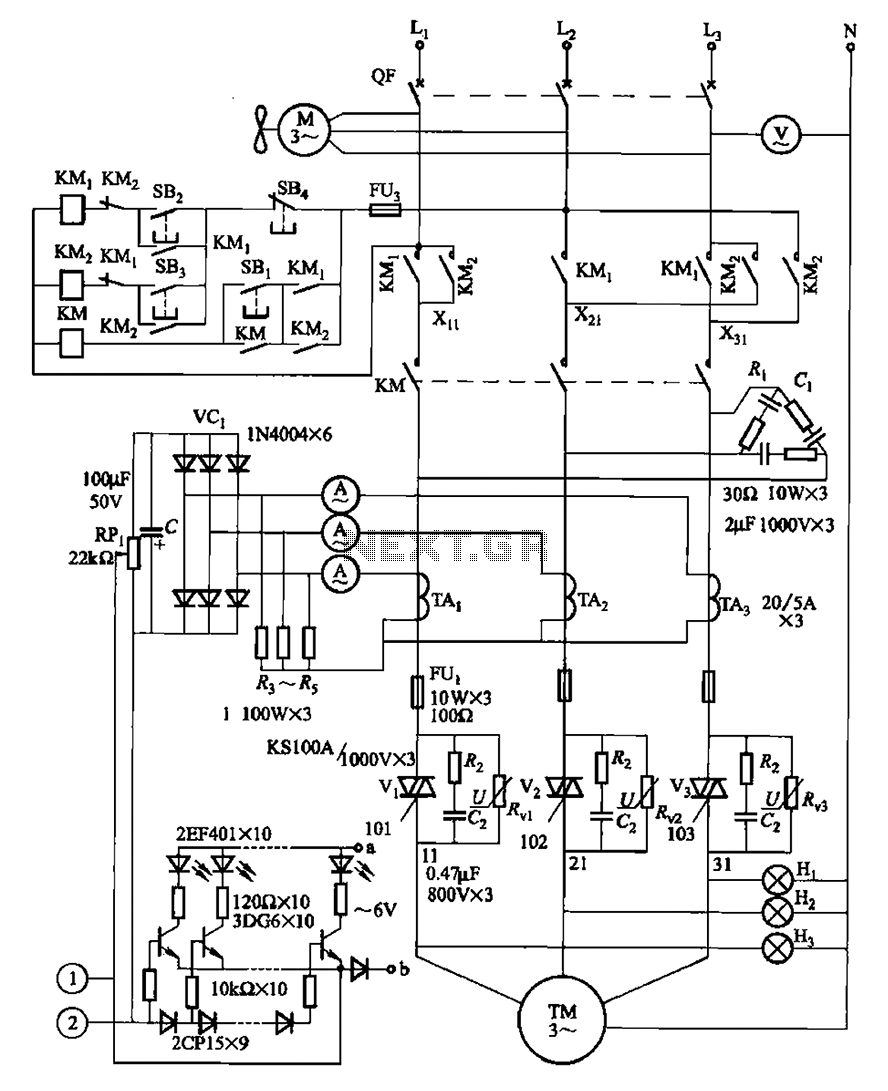

The circuit illustrated in Figure 3-178 is designed for controlling the speed and torque of a motor used in a continuous casting machine. It consists of the main circuit, a trigger circuit, and both manual and automatic control signal circuits, along with a level indicator and other components. This circuit is integral to the operation of the casting machine, facilitating precise motor speed control and monitoring.

The circuit for the continuous casting machine motor speed control incorporates several key components that work together to ensure efficient operation. The main circuit is responsible for the overall power distribution and control of the motor. It typically includes a power supply, motor driver, and safety features to protect against overloads or faults.

The trigger circuit plays a crucial role in initiating the motor operation. It can be activated manually or automatically, depending on the requirements of the casting process. Manual control allows for direct operator input, enabling adjustments based on real-time conditions. In contrast, the automatic control signal circuit utilizes feedback from various sensors to optimize motor performance without human intervention.

The level indicator is an important component, providing visual feedback on the operational status of the casting machine. It monitors parameters such as motor speed and torque, ensuring that the system operates within designated limits. This information can be critical for maintaining product quality and preventing equipment damage.

In summary, the motor speed control circuit for the continuous casting machine is a sophisticated system that integrates multiple elements to achieve reliable and efficient operation. The combination of manual and automatic controls, along with feedback mechanisms, enhances the overall performance and safety of the casting process. Circuit shown in Figure 3-178. It withered speed torque motor for continuous casting machine, the circuit from the main circuit, trigger circuit, manual and automatic control s ignal circuit and the level indicator and other components. O casting machine motor speed control circuit and the main level indicating circuit (Figure 3-178)

The circuit for the continuous casting machine motor speed control incorporates several key components that work together to ensure efficient operation. The main circuit is responsible for the overall power distribution and control of the motor. It typically includes a power supply, motor driver, and safety features to protect against overloads or faults.

The trigger circuit plays a crucial role in initiating the motor operation. It can be activated manually or automatically, depending on the requirements of the casting process. Manual control allows for direct operator input, enabling adjustments based on real-time conditions. In contrast, the automatic control signal circuit utilizes feedback from various sensors to optimize motor performance without human intervention.

The level indicator is an important component, providing visual feedback on the operational status of the casting machine. It monitors parameters such as motor speed and torque, ensuring that the system operates within designated limits. This information can be critical for maintaining product quality and preventing equipment damage.

In summary, the motor speed control circuit for the continuous casting machine is a sophisticated system that integrates multiple elements to achieve reliable and efficient operation. The combination of manual and automatic controls, along with feedback mechanisms, enhances the overall performance and safety of the casting process. Circuit shown in Figure 3-178. It withered speed torque motor for continuous casting machine, the circuit from the main circuit, trigger circuit, manual and automatic control s ignal circuit and the level indicator and other components. O casting machine motor speed control circuit and the main level indicating circuit (Figure 3-178)