One of reversing circuit reverse braking resistor in series with a DC motor armature start

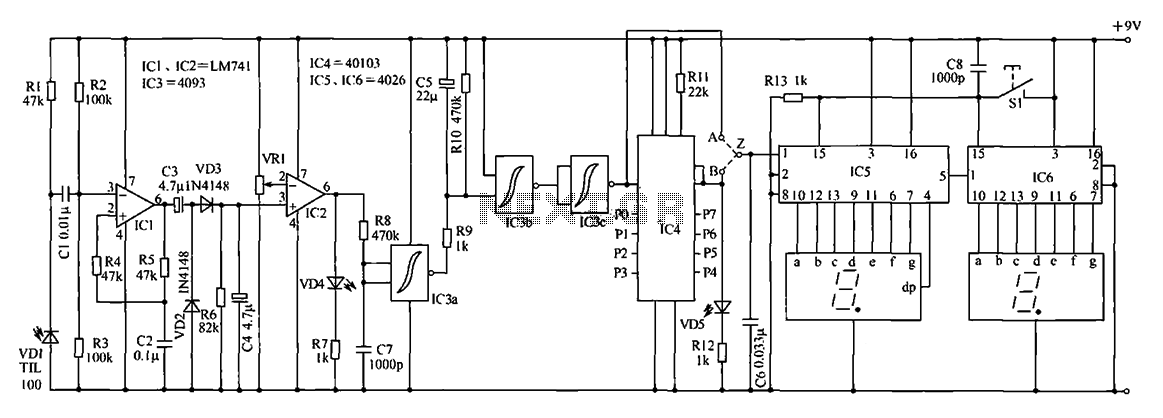

The circuit depicted in Figure 3-201 includes two starting resistors, with one controlled by a time relay. A master switch (SA) is utilized to manage the motor's reversing operation. The circuit incorporates a reverse braking mechanism, which is automatically controlled based on the motor's size and speed. This configuration is suitable for series-wound, shunt, and compound excitation type DC motors. In the circuit, Rz and Ra serve as starting resistors, while Ri functions as a reverse flow limiting resistor. During the reverse braking process, Ri is integrated into the armature circuit to restrict reverse current. When the motor transitions from a standstill to reverse, Ri is bypassed to ensure normal operation, allowing the discharge resistor R4 to function. KMi represents the forward contactor, KM2 denotes the reverse contactor, KM3 is the main circuit (armature) contactor, and KM4 is the reverse brake connector. An overcurrent relay (KI) is included for overload and short-circuit protection.

The circuit in question is designed to facilitate the controlled operation of DC motors, particularly in applications requiring both forward and reverse motion. It utilizes a combination of starting resistors to manage the initial current during motor startup, which is critical in preventing damage to the motor. The time relay adds an element of automation, allowing for a delay before the starting resistor is cut out of the circuit, thereby providing a smooth transition between starting and operational phases.

The reverse braking system is a pivotal feature of this circuit, allowing the motor to decelerate efficiently when reversing direction. The use of the reverse flow limiting resistor (Ri) is essential, as it prevents excessive reverse current that could potentially harm the motor or the overall circuit. The design ensures that during the braking phase, the circuit maintains control over the armature current, which is vital for the safe operation of the motor.

Contactor components (KMi, KM2, KM3, and KM4) play significant roles in directing the flow of electricity within the circuit. The forward and reverse contactors enable the motor to switch directions seamlessly, while the main circuit contactor ensures that the motor receives the appropriate power supply during operation. The inclusion of an overcurrent relay (KI) is a critical safety feature, providing protection against potential overloads and short circuits, which are common risks in motor operations.

Overall, this circuit exemplifies a robust design that addresses the complexities of motor control, emphasizing safety, efficiency, and versatility across different types of DC motor configurations. Circuit shown in Figure 3-201. The circuit has two starting resistor, starting resistor controlled by the time relay cut; SA by a master switch to control the motor reversing o peration; shut down, the use of reverse brake, reverse braking is based on motor size Speed automatic control. This circuit series-wound type, shunt and compound excitation type DC motors are applicable. Figure, Rz, Ra to start resistance; Ri is reverse flow limiting resistor, the braking process in reverse access armature circuit to limit the reverse current brake.

When the motor speed from zero to start reverse, Ri is short, does not affect the normal reverse L start the discharge resistor R4; KMi is forward contactor; KM2 to reverse contactors; KM3 main circuit (armature ) contactor; KM4 to reverse brake connector. Overcurrent relay KI for overload and short circuit protection.

The circuit in question is designed to facilitate the controlled operation of DC motors, particularly in applications requiring both forward and reverse motion. It utilizes a combination of starting resistors to manage the initial current during motor startup, which is critical in preventing damage to the motor. The time relay adds an element of automation, allowing for a delay before the starting resistor is cut out of the circuit, thereby providing a smooth transition between starting and operational phases.

The reverse braking system is a pivotal feature of this circuit, allowing the motor to decelerate efficiently when reversing direction. The use of the reverse flow limiting resistor (Ri) is essential, as it prevents excessive reverse current that could potentially harm the motor or the overall circuit. The design ensures that during the braking phase, the circuit maintains control over the armature current, which is vital for the safe operation of the motor.

Contactor components (KMi, KM2, KM3, and KM4) play significant roles in directing the flow of electricity within the circuit. The forward and reverse contactors enable the motor to switch directions seamlessly, while the main circuit contactor ensures that the motor receives the appropriate power supply during operation. The inclusion of an overcurrent relay (KI) is a critical safety feature, providing protection against potential overloads and short circuits, which are common risks in motor operations.

Overall, this circuit exemplifies a robust design that addresses the complexities of motor control, emphasizing safety, efficiency, and versatility across different types of DC motor configurations. Circuit shown in Figure 3-201. The circuit has two starting resistor, starting resistor controlled by the time relay cut; SA by a master switch to control the motor reversing o peration; shut down, the use of reverse brake, reverse braking is based on motor size Speed automatic control. This circuit series-wound type, shunt and compound excitation type DC motors are applicable. Figure, Rz, Ra to start resistance; Ri is reverse flow limiting resistor, the braking process in reverse access armature circuit to limit the reverse current brake.

When the motor speed from zero to start reverse, Ri is short, does not affect the normal reverse L start the discharge resistor R4; KMi is forward contactor; KM2 to reverse contactors; KM3 main circuit (armature ) contactor; KM4 to reverse brake connector. Overcurrent relay KI for overload and short circuit protection.