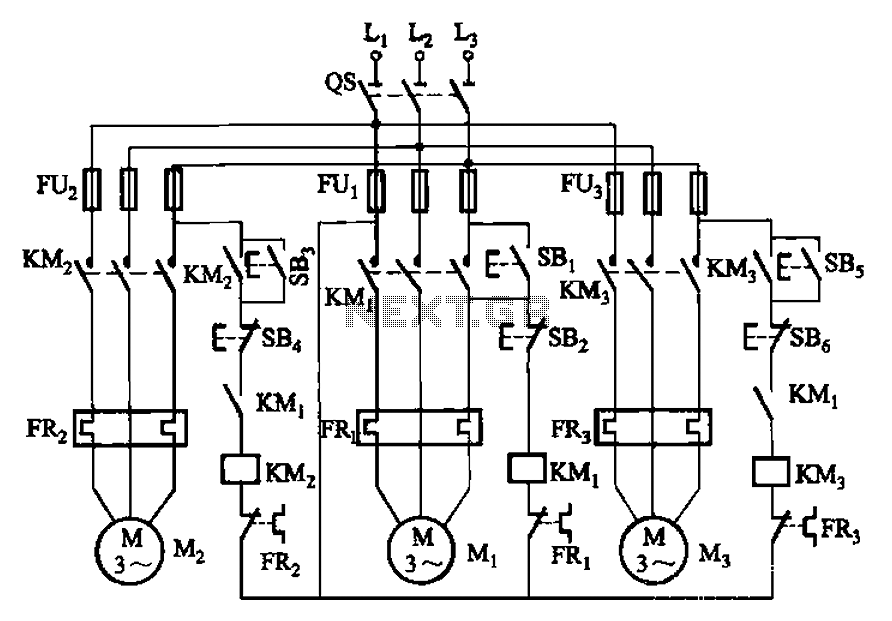

Three motor control circuit start and stop sequence requirements

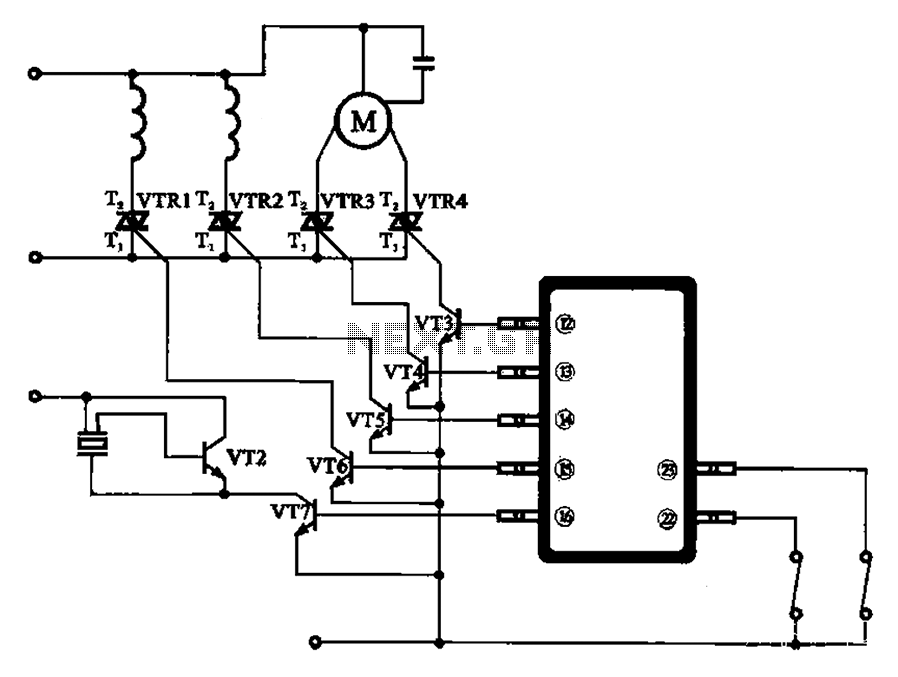

The circuit shown in Figure 3-89 illustrates a system where starting motor M1 allows motors M2 and M3 to initiate operation. Upon shutdown, motor Mz can be stopped first; however, once motor M1 is stopped (by pressing switch SB2), motors M2 and M3 will also cease operation.

The circuit utilizes a sequential control mechanism to manage the operation of multiple motors. Motor M1 acts as the primary motor, and its activation is critical for the operation of motors M2 and M3. This configuration ensures that the motors are interdependent, where the starting of M2 and M3 is contingent upon the operational status of M1.

The shutdown sequence is designed to prioritize the stopping of motor Mz, which can be halted independently of the other motors. This feature provides flexibility in controlling the system, allowing for maintenance or safety protocols to be enacted without affecting the entire circuit.

The inclusion of switch SB2 serves as a manual control point for stopping motor M1. When SB2 is activated, it triggers a response that leads to the immediate shutdown of motors M2 and M3, thereby ensuring that all motors are synchronized in their operation and shutdown processes.

This design is particularly useful in applications where motors are part of a larger system, such as in conveyor belts or assembly lines, where the coordinated operation of multiple motors is essential for efficiency and safety. The circuit can be further enhanced with additional features such as overload protection, thermal sensors, or automated control systems for improved performance and reliability. Circuit shown in Figure 3-89. After starting the motor Mi can guarantee, it allowed the other two to start the motor. Shutdown, power motivation Mz, can first stop, but as long as the motor M1 stop (press SB2), the motor M2, M3 also stop.

The circuit utilizes a sequential control mechanism to manage the operation of multiple motors. Motor M1 acts as the primary motor, and its activation is critical for the operation of motors M2 and M3. This configuration ensures that the motors are interdependent, where the starting of M2 and M3 is contingent upon the operational status of M1.

The shutdown sequence is designed to prioritize the stopping of motor Mz, which can be halted independently of the other motors. This feature provides flexibility in controlling the system, allowing for maintenance or safety protocols to be enacted without affecting the entire circuit.

The inclusion of switch SB2 serves as a manual control point for stopping motor M1. When SB2 is activated, it triggers a response that leads to the immediate shutdown of motors M2 and M3, thereby ensuring that all motors are synchronized in their operation and shutdown processes.

This design is particularly useful in applications where motors are part of a larger system, such as in conveyor belts or assembly lines, where the coordinated operation of multiple motors is essential for efficiency and safety. The circuit can be further enhanced with additional features such as overload protection, thermal sensors, or automated control systems for improved performance and reliability. Circuit shown in Figure 3-89. After starting the motor Mi can guarantee, it allowed the other two to start the motor. Shutdown, power motivation Mz, can first stop, but as long as the motor M1 stop (press SB2), the motor M2, M3 also stop.