2500W Phase Control

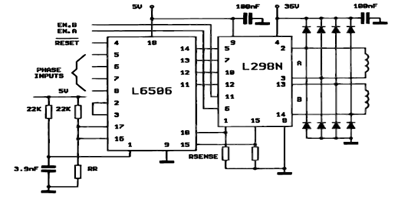

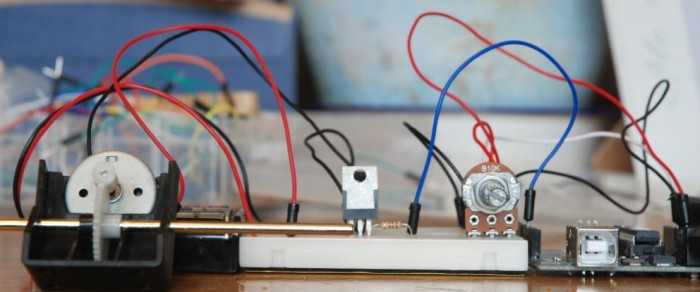

This circuit controls resistive and inductive loads up to 2,500W. Its primary component is the Siemens TLE3103 integrated phase control circuit, which includes its own power supply, a zero voltage crossing detector, and a logic driver. An additional feature is a low voltage input that enables or disables triac firing and the logic driver. The operational function is as follows: when pin 13 of the TLE3103 is open (floating), the trigger output is active; when tied to ground, the trigger output is disabled. An UP and a DOWN pushbutton control a 32-step digital potentiometer (IC2, AD5228) through a debouncer (IC1, MAX6817). The digital potentiometer has a power-on reset pin that can be connected to ground to initiate at midscale or to VCC to start at zero scale. The desired function is selectable via jumper JP1. The triac, capable of driving loads up to 40A, is the BTA41, which has an isolated body, reducing the risk of handling the board under voltage. The snubber circuit employs a 68 μH inductance, which can be replaced with a 100 Ω resistor. If the inductance is replaced, capacitor C5 should be valued at 47nF. It is noteworthy that the debouncer circuit is manufactured in a SOT23-6 package and can be soldered directly onto the board (DIP-6 package) using thin wires or an adapter board.

This circuit is designed for controlling high-power resistive and inductive loads while ensuring safety and functionality through sophisticated components and configurations. The Siemens TLE3103 serves as the heart of the control mechanism, providing phase control capabilities essential for managing the load effectively. With its integrated power supply and zero voltage crossing detection, the TLE3103 minimizes electrical noise and enhances the reliability of the circuit.

The circuit’s operation is intuitively managed through a pair of pushbuttons, which adjust the output of the digital potentiometer, allowing for precise control over the load's power level. The debouncer IC (MAX6817) ensures that the pushbutton inputs are stable, eliminating the effects of mechanical bouncing that can lead to erratic behavior in digital circuits. The choice of the AD5228 digital potentiometer allows for a significant range of adjustment, with the potential for midscale or zero scale startup configurations depending on the jumper setting.

The use of the BTA41 triac, while rated for higher currents than necessary, provides an added layer of safety due to its isolated body, which is particularly advantageous when handling the circuit under load conditions. The snubber circuit, consisting of a 68 μH inductor, is critical for suppressing voltage spikes that can occur during the switching of inductive loads. The option to replace the inductor with a resistor offers flexibility in design, with the requirement to adjust the capacitor value accordingly to maintain circuit performance.

Overall, this circuit exemplifies a well-engineered solution for controlling high-power loads, integrating user-friendly controls and robust components to ensure both functionality and safety in operation.This circuit controls resistive and inductive loads up to 2, 500W. Its main functional device is an integrated phase control circuit - Siemens TLE3103. It contains its own power supply, a zero voltage crossing detector circuit and a logic driver. An additional feature is the low voltage input to enable/disable triac firing enabling/disabling the lo gic driver. The function is as follows: pin13 TLE3103 open (floating), trigger output active, tied to ground trigger output disabled. An UP and a DOWN pushbutton control a 32-step digital potentiometer (IC2, AD5228) via the debouncer IC1 (MAX6817).

The digital potentiometer has a power on reset pin which might be tied to ground causing the potentiometer to start at midscale, or to VCC causing it to start at zero scale. The desired function is selectable using jumper JP1. The triac (capable of driving 40A loads) is a bit overkill for the desired power but the BTA41 has an isolated body and therefore handling of the board under voltage is less dangerous as it is with phase on the package.

The snubber circuit uses a 68 H inductance but this might be replaced with a 100 resistor. When replacing the inductance C5 should have a value of 47nF. Remark: The debouncer circuit is manufactured with a SOT23-6 package. It might be soldered directly onto the board (DIP-6 package) using thin wires or an adapter board. 🔗 External reference

This circuit is designed for controlling high-power resistive and inductive loads while ensuring safety and functionality through sophisticated components and configurations. The Siemens TLE3103 serves as the heart of the control mechanism, providing phase control capabilities essential for managing the load effectively. With its integrated power supply and zero voltage crossing detection, the TLE3103 minimizes electrical noise and enhances the reliability of the circuit.

The circuit’s operation is intuitively managed through a pair of pushbuttons, which adjust the output of the digital potentiometer, allowing for precise control over the load's power level. The debouncer IC (MAX6817) ensures that the pushbutton inputs are stable, eliminating the effects of mechanical bouncing that can lead to erratic behavior in digital circuits. The choice of the AD5228 digital potentiometer allows for a significant range of adjustment, with the potential for midscale or zero scale startup configurations depending on the jumper setting.

The use of the BTA41 triac, while rated for higher currents than necessary, provides an added layer of safety due to its isolated body, which is particularly advantageous when handling the circuit under load conditions. The snubber circuit, consisting of a 68 μH inductor, is critical for suppressing voltage spikes that can occur during the switching of inductive loads. The option to replace the inductor with a resistor offers flexibility in design, with the requirement to adjust the capacitor value accordingly to maintain circuit performance.

Overall, this circuit exemplifies a well-engineered solution for controlling high-power loads, integrating user-friendly controls and robust components to ensure both functionality and safety in operation.This circuit controls resistive and inductive loads up to 2, 500W. Its main functional device is an integrated phase control circuit - Siemens TLE3103. It contains its own power supply, a zero voltage crossing detector circuit and a logic driver. An additional feature is the low voltage input to enable/disable triac firing enabling/disabling the lo gic driver. The function is as follows: pin13 TLE3103 open (floating), trigger output active, tied to ground trigger output disabled. An UP and a DOWN pushbutton control a 32-step digital potentiometer (IC2, AD5228) via the debouncer IC1 (MAX6817).

The digital potentiometer has a power on reset pin which might be tied to ground causing the potentiometer to start at midscale, or to VCC causing it to start at zero scale. The desired function is selectable using jumper JP1. The triac (capable of driving 40A loads) is a bit overkill for the desired power but the BTA41 has an isolated body and therefore handling of the board under voltage is less dangerous as it is with phase on the package.

The snubber circuit uses a 68 H inductance but this might be replaced with a 100 resistor. When replacing the inductance C5 should have a value of 47nF. Remark: The debouncer circuit is manufactured with a SOT23-6 package. It might be soldered directly onto the board (DIP-6 package) using thin wires or an adapter board. 🔗 External reference

Warning: include(partials/cookie-banner.php): Failed to open stream: Permission denied in /var/www/html/nextgr/view-circuit.php on line 713

Warning: include(): Failed opening 'partials/cookie-banner.php' for inclusion (include_path='.:/usr/share/php') in /var/www/html/nextgr/view-circuit.php on line 713