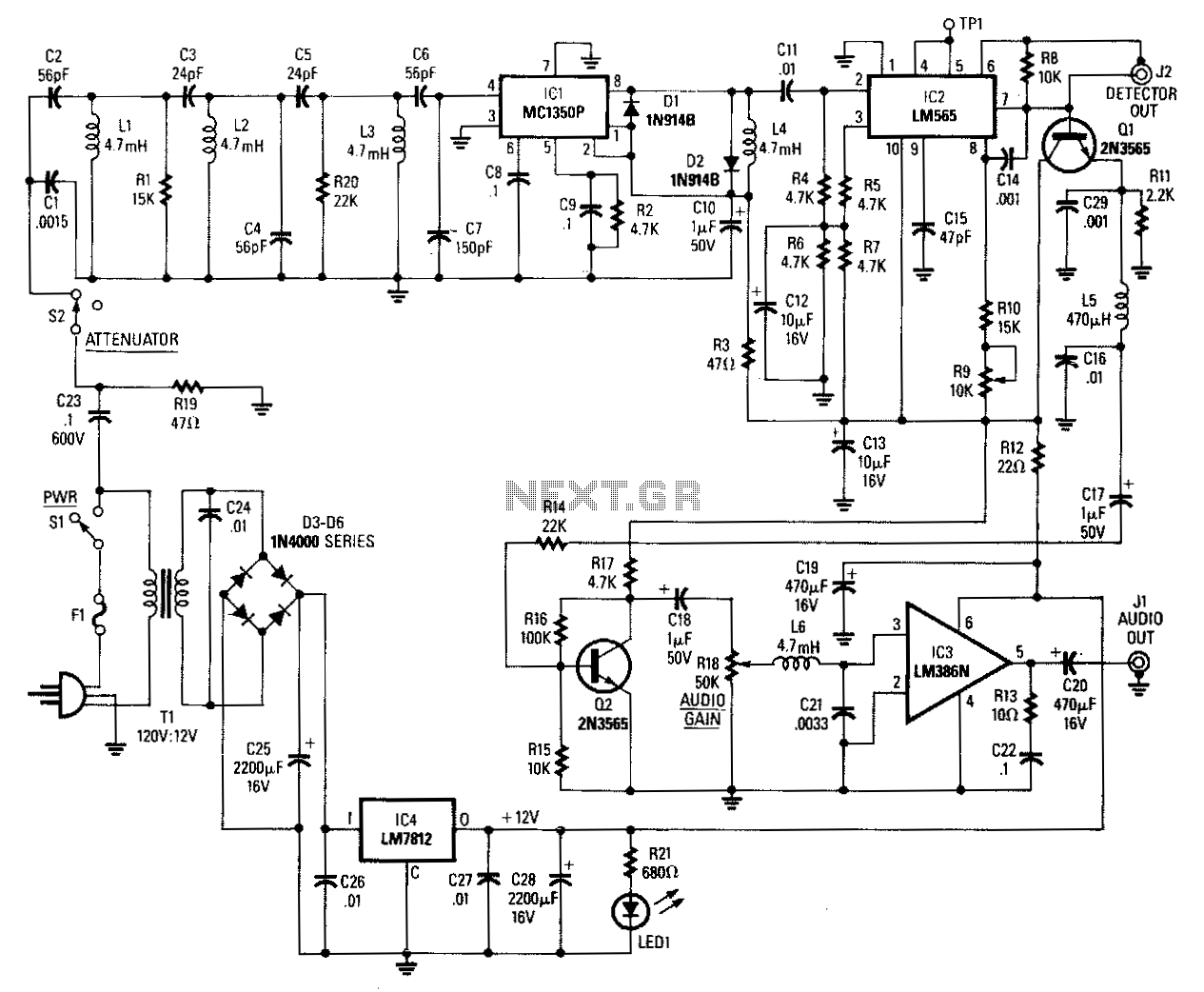

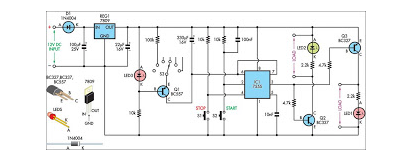

4-20mA Current Loop Tester

This design will interest technicians who work on pneumatically operated valves and other 4-20mA current loop controlled devices. Although the 4-20mA signal is commonly used in industrial applications for transmitting sensor data and controlling devices, it is essential to understand its operation and integration in various systems.

The 4-20mA current loop is a standard method for transmitting analog signals over long distances in industrial environments. It is particularly advantageous due to its noise immunity and the ability to transmit signals over significant distances without degradation. The loop operates by sending a current signal, where 4mA represents the lower limit of the measurement range (often indicating a zero or minimum value), and 20mA signifies the upper limit (indicating full scale or maximum value).

In the context of pneumatically operated valves, the 4-20mA signal can be used to control the position of the valve actuator. The actuator receives the current signal and converts it into a proportional movement of the valve, allowing for precise control of fluid flow. The system typically includes a transmitter that converts the variable physical parameter (such as pressure or temperature) into a 4-20mA signal, which is then sent to the actuator.

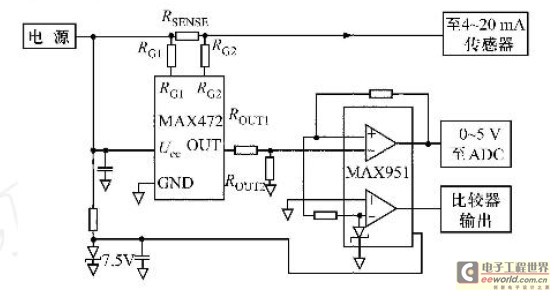

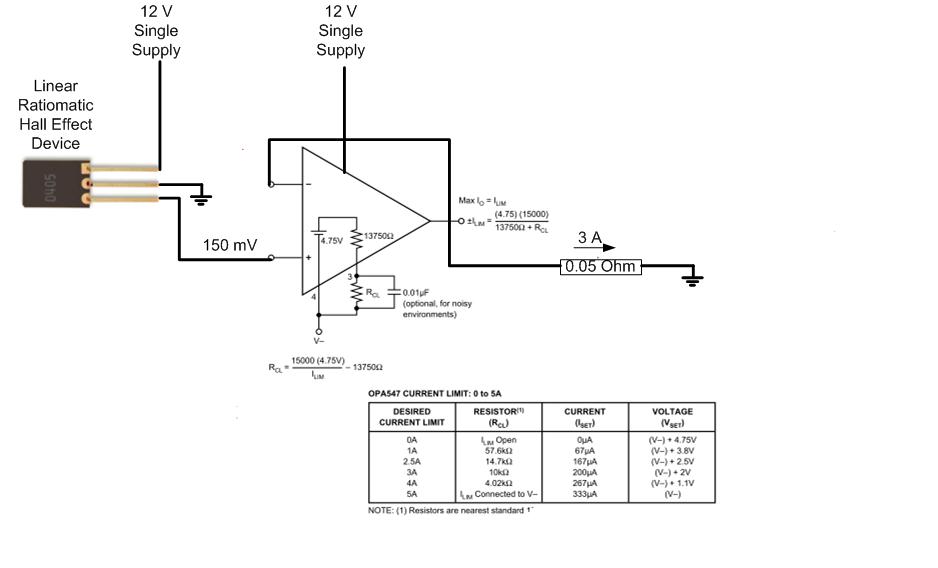

The integration of 4-20mA devices requires careful consideration of the power supply, as the current loop must be powered adequately to ensure accurate signal transmission. A common configuration includes a power supply connected in series with the transmitter and the actuator, ensuring that the total loop resistance does not exceed the power supply's voltage rating divided by the loop current.

Additionally, for troubleshooting and maintenance, incorporating diagnostic features such as loop testing and fault indication can enhance the reliability of the system. Technicians can utilize multimeters or specialized loop calibrators to monitor the current signal and verify the integrity of the loop.

In summary, the design focusing on 4-20mA current loop controlled devices, particularly in the context of pneumatically operated valves, offers a robust solution for precise control and monitoring in industrial applications. Understanding the operational principles and integration methods is crucial for technicians working with these systems, ensuring optimal performance and reliability.This design will interest technicians who work on pneumatically operated valves and other 4-20mA current loop controlled devices. Although 4-20mA signal i.. 🔗 External reference

The 4-20mA current loop is a standard method for transmitting analog signals over long distances in industrial environments. It is particularly advantageous due to its noise immunity and the ability to transmit signals over significant distances without degradation. The loop operates by sending a current signal, where 4mA represents the lower limit of the measurement range (often indicating a zero or minimum value), and 20mA signifies the upper limit (indicating full scale or maximum value).

In the context of pneumatically operated valves, the 4-20mA signal can be used to control the position of the valve actuator. The actuator receives the current signal and converts it into a proportional movement of the valve, allowing for precise control of fluid flow. The system typically includes a transmitter that converts the variable physical parameter (such as pressure or temperature) into a 4-20mA signal, which is then sent to the actuator.

The integration of 4-20mA devices requires careful consideration of the power supply, as the current loop must be powered adequately to ensure accurate signal transmission. A common configuration includes a power supply connected in series with the transmitter and the actuator, ensuring that the total loop resistance does not exceed the power supply's voltage rating divided by the loop current.

Additionally, for troubleshooting and maintenance, incorporating diagnostic features such as loop testing and fault indication can enhance the reliability of the system. Technicians can utilize multimeters or specialized loop calibrators to monitor the current signal and verify the integrity of the loop.

In summary, the design focusing on 4-20mA current loop controlled devices, particularly in the context of pneumatically operated valves, offers a robust solution for precise control and monitoring in industrial applications. Understanding the operational principles and integration methods is crucial for technicians working with these systems, ensuring optimal performance and reliability.This design will interest technicians who work on pneumatically operated valves and other 4-20mA current loop controlled devices. Although 4-20mA signal i.. 🔗 External reference