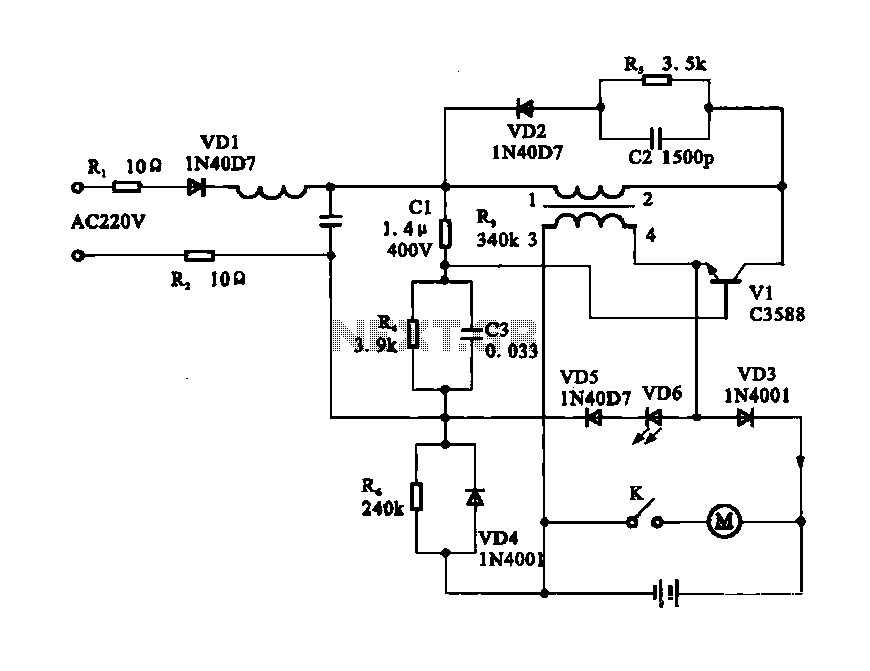

555 IC PWM Motor Control with Current Limiter

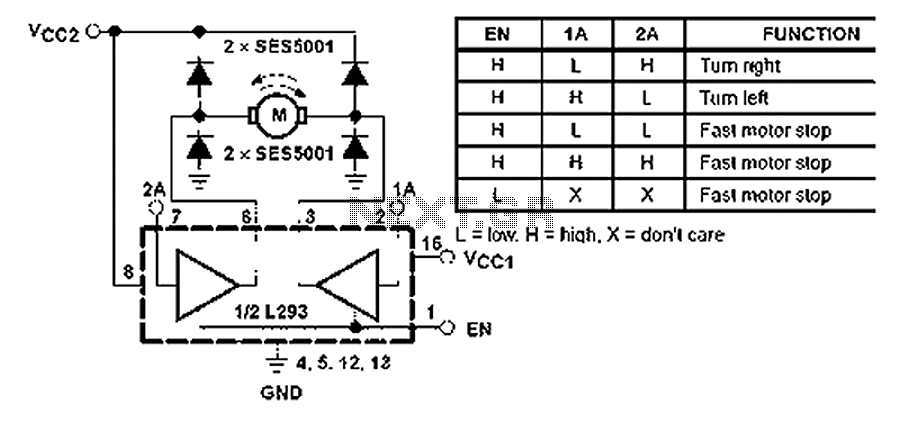

To provide rapid motor speed changes and motor direction reversal, four outputs drive a MOSFET H-bridge. N-channel devices serve as the lower rail power MOSFETs, while P-channel devices are utilized as the upper MOSFETs. All MOSFETs are controlled by the TC4469. A small series resistor is included to prevent gate oscillation and to slow the transition time in the lower rail devices, which helps keep the upper device turned OFF. A resistor divider and a low-cost level shift transistor can be added easily and economically to maintain a 15VDC gate drive for the upper rail MOSFETs when motor voltages exceed 12VDC. A simple linear regulator can power these from the positive motor supply when it is above 15VDC, as the ICM7555 and TC4469 require negligible current. To protect the gates from supply transients, Zener diodes can be employed. When the lower MOSFET in the same leg turns ON, causing a high dV/dT, gate-to-source capacitors help keep the upper MOSFETs OFF. Additionally, maintaining low gate drive impedance for the upper MOSFETs in the OFF state can further mitigate this issue. A sense resistor placed in the ground leg of the H-bridge provides an easy method to sense motor current pulse by pulse, regardless of the motor's forward or reverse rotation. This signal is filtered and applied to the ICM7555 to inhibit PWM generation if the motor current exceeds the permissible value.

The described circuit employs a MOSFET H-bridge configuration to enable rapid adjustments in motor speed and direction. The H-bridge consists of four MOSFETs, specifically N-channel types for the lower rail and P-channel types for the upper rail. The TC4469 driver is responsible for controlling the gate signals of these MOSFETs, ensuring efficient switching and performance.

To enhance the reliability of the gate control, a small series resistor is incorporated into the design. This resistor serves two primary purposes: it dampens potential oscillations at the gate and slows down the transition times for the lower rail MOSFETs, which is critical for ensuring that the upper rail MOSFETs remain OFF during switching events. This design consideration reduces the risk of unintended turn-on of the upper MOSFETs, thereby improving the overall stability of the H-bridge operation.

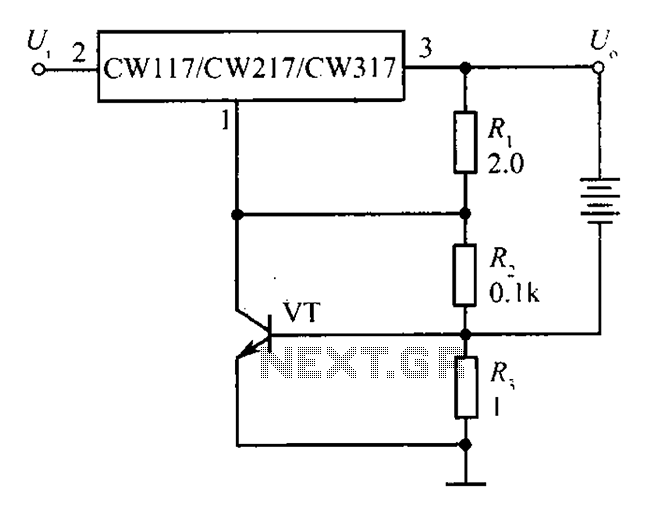

In applications where the motor voltage exceeds 12VDC, maintaining a consistent gate voltage of 15VDC for the upper rail MOSFETs is crucial. A resistor divider and a low-cost level-shifting transistor can be integrated into the circuit to achieve this requirement economically. When the motor supply voltage is above 15VDC, a linear regulator can be employed to derive the necessary gate drive voltage for the upper MOSFETs, ensuring that the TC4469 and ICM7555 operate efficiently without drawing significant current.

Protection against supply transients is another essential aspect of the design. The inclusion of Zener diodes serves as a safeguard for the gate terminals, mitigating the risk of damage from voltage spikes. Furthermore, the use of gate-to-source capacitors plays a vital role in maintaining the upper MOSFETs in the OFF state when the lower MOSFETs are activated, especially during high dV/dT conditions.

Current sensing is facilitated through the use of a sense resistor located in the ground leg of the H-bridge. This configuration allows for accurate monitoring of the motor current on a pulse-by-pulse basis, regardless of the direction of rotation. The sensed current signal is filtered and fed into the ICM7555, which can inhibit PWM generation if the current exceeds predefined limits, thus protecting the motor and driver circuit from potential damage due to overcurrent conditions.

This comprehensive approach ensures robust control of motor operations, combining efficient drive techniques, protective measures, and effective current sensing to enhance the performance and reliability of the motor control system.To provide rapid motor speed changes and motor direction reversal, four outputs drive a MOSFET H-bridge. N-channel devices are the lower rail power MOSFETs and P-channels are the upper MOSFETs. All of them are driven by the TC4469. A small series resistor helps prevent gate oscillation and slows transition time in the lower rail devices, helping t

he upper device to stay OFF. A resistor divider and low-cost level shift transistor can be added easily and economically to maintain a 15VDC gate drive for the upper rail MOSFETs for motor voltages over 12VDC. A simple linear regulator can power them from the positive motor supply when it is above 15VDC since the ICM7555 and TC4469 need negligible current.

To help protect the gates from supply transients, we can use a Zener diodes. When the lower MOSFET in the same leg turns ON , causing a high dV/dT, gate-to-source capacitors help keep the upper MOSFETs OFF . The other way to help that situation is keeping the upper MOSFET gate drive impedance low in the OFF state.

An easy way to sense motor current, pulse by pulse, regardless of forward or reverse motor rotation is provided by a sense resistor in the ground leg of the H-bridge. To inhibit PWM generation if motor current exceeds the allowed value, this signal is filtered and applied to the ICM7555.

[Microchip Application Notes] We aim to transmit more information by carrying articles. Please send us an E-mail to wanghuali@hqew. net within 15 days if we are involved in the problems of article content, copyright or other problems. We will delete it soon. 🔗 External reference

The described circuit employs a MOSFET H-bridge configuration to enable rapid adjustments in motor speed and direction. The H-bridge consists of four MOSFETs, specifically N-channel types for the lower rail and P-channel types for the upper rail. The TC4469 driver is responsible for controlling the gate signals of these MOSFETs, ensuring efficient switching and performance.

To enhance the reliability of the gate control, a small series resistor is incorporated into the design. This resistor serves two primary purposes: it dampens potential oscillations at the gate and slows down the transition times for the lower rail MOSFETs, which is critical for ensuring that the upper rail MOSFETs remain OFF during switching events. This design consideration reduces the risk of unintended turn-on of the upper MOSFETs, thereby improving the overall stability of the H-bridge operation.

In applications where the motor voltage exceeds 12VDC, maintaining a consistent gate voltage of 15VDC for the upper rail MOSFETs is crucial. A resistor divider and a low-cost level-shifting transistor can be integrated into the circuit to achieve this requirement economically. When the motor supply voltage is above 15VDC, a linear regulator can be employed to derive the necessary gate drive voltage for the upper MOSFETs, ensuring that the TC4469 and ICM7555 operate efficiently without drawing significant current.

Protection against supply transients is another essential aspect of the design. The inclusion of Zener diodes serves as a safeguard for the gate terminals, mitigating the risk of damage from voltage spikes. Furthermore, the use of gate-to-source capacitors plays a vital role in maintaining the upper MOSFETs in the OFF state when the lower MOSFETs are activated, especially during high dV/dT conditions.

Current sensing is facilitated through the use of a sense resistor located in the ground leg of the H-bridge. This configuration allows for accurate monitoring of the motor current on a pulse-by-pulse basis, regardless of the direction of rotation. The sensed current signal is filtered and fed into the ICM7555, which can inhibit PWM generation if the current exceeds predefined limits, thus protecting the motor and driver circuit from potential damage due to overcurrent conditions.

This comprehensive approach ensures robust control of motor operations, combining efficient drive techniques, protective measures, and effective current sensing to enhance the performance and reliability of the motor control system.To provide rapid motor speed changes and motor direction reversal, four outputs drive a MOSFET H-bridge. N-channel devices are the lower rail power MOSFETs and P-channels are the upper MOSFETs. All of them are driven by the TC4469. A small series resistor helps prevent gate oscillation and slows transition time in the lower rail devices, helping t

he upper device to stay OFF. A resistor divider and low-cost level shift transistor can be added easily and economically to maintain a 15VDC gate drive for the upper rail MOSFETs for motor voltages over 12VDC. A simple linear regulator can power them from the positive motor supply when it is above 15VDC since the ICM7555 and TC4469 need negligible current.

To help protect the gates from supply transients, we can use a Zener diodes. When the lower MOSFET in the same leg turns ON , causing a high dV/dT, gate-to-source capacitors help keep the upper MOSFETs OFF . The other way to help that situation is keeping the upper MOSFET gate drive impedance low in the OFF state.

An easy way to sense motor current, pulse by pulse, regardless of forward or reverse motor rotation is provided by a sense resistor in the ground leg of the H-bridge. To inhibit PWM generation if motor current exceeds the allowed value, this signal is filtered and applied to the ICM7555.

[Microchip Application Notes] We aim to transmit more information by carrying articles. Please send us an E-mail to wanghuali@hqew. net within 15 days if we are involved in the problems of article content, copyright or other problems. We will delete it soon. 🔗 External reference