555 Timer As A Switch-Mode Power Supply

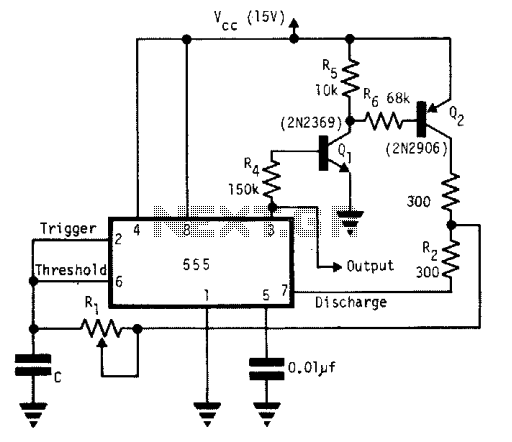

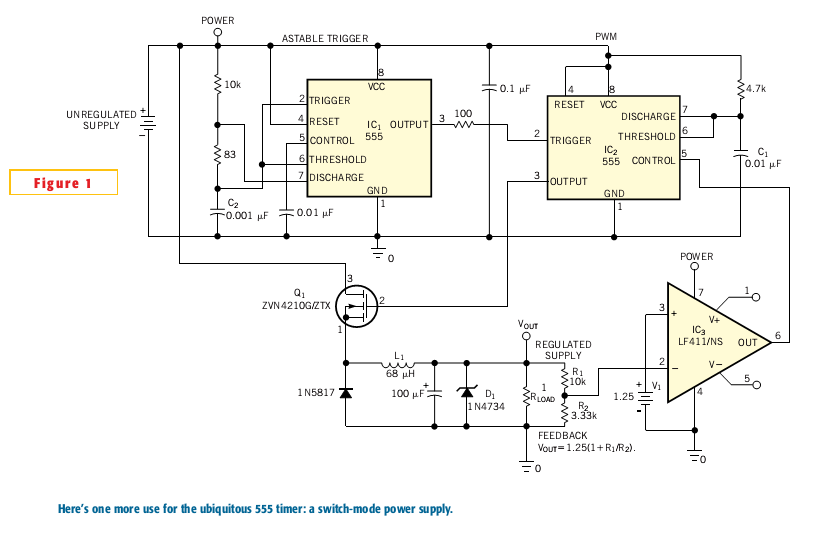

Most switch-mode power supplies utilize a PWM (pulse-width-modulated) output that is regulated through voltage feedback. A 555-timer IC can be used to generate PWM at a low cost. The circuit diagram illustrates how to convert a 555 PWM circuit into a switch-mode power supply using a straightforward equation. The design incorporates two 555 ICs. IC1 operates in astable mode and triggers IC2, which is configured in PWM mode. IC1 is set to oscillate at approximately 60 kHz with a high duty cycle. The output remains low for about 2.5 µsec to activate the PWM circuit, then goes high for the remainder of the period. The PWM circuit can achieve a maximum pulse width of approximately 85 µsec, which decreases based on the control voltage from the feedback loop. The chip count can be minimized by using a 556 IC or another continuous-trigger source. The input voltage must be at least (1.5VOUT + Margin), meaning that for a 5V output, a minimum input of 9V is required. Utilizing CMOS chips and small timing capacitors C1 and C2 helps to maintain a low operating current. A simple zener-diode regulator can be used for the 555 IC, allowing the input voltage to exceed 30V. The input voltage limit depends on the zener supply's power handling capability while providing 5 to 10 mA to the 555 ICs. Q1 is designed with low RDS(ON) and low VGS, capable of withstanding over 40V. D1 is employed to clamp voltage spikes that may occur when a large current flow stops, which can leave a significant magnetic field in the inductor. D1 should be selected based on the required output voltage; for a 5V output, a 5.6V zener diode is recommended. IC3, R1, R2, and V1 create the feedback circuit that establishes the output voltage, described by the equation VOUT = V1(R1/R2 + 1). The TL431 is a commonly used component for voltage reference and can easily provide the 1.25V for V1. This design can deliver 5V at 1.5A with an input voltage range of 9 to 40V. When the input exceeds 12V, a 10V zener-diode supply can be added for the chips, which only slightly affects efficiency. With a 12V input, the efficiency for a 5V, 1.5A output is approximately 70%, dropping to 65% with a 40V input and a zener circuit. The impact of the zener diode is more pronounced at lower current levels, resulting in approximately 50% efficiency at a 50 mA load.

The circuit employs two 555 timer ICs to generate a PWM signal that is essential for the operation of the switch-mode power supply. The first 555 timer (IC1) operates in astable mode, generating a continuous square wave at a frequency of approximately 60 kHz. This frequency is chosen to optimize the switching performance and efficiency of the power supply. The duty cycle is adjusted so that the output remains low for about 2.5 µsec, which serves as the trigger for the second 555 timer (IC2), configured in PWM mode. The PWM output of IC2 is critical for regulating the output voltage of the power supply.

The feedback mechanism is established through the use of a voltage divider formed by resistors R1 and R2, with V1 providing a reference voltage. The output voltage can be calculated using the formula VOUT = V1(R1/R2 + 1), which allows for precise control over the output voltage based on the resistor values. The TL431 voltage reference is a reliable choice for providing the necessary 1.25V reference voltage.

The design also incorporates a zener diode (D1) for voltage spike protection, ensuring the stability of the circuit during transient conditions. The choice of components, including the selection of Q1 with low RDS(ON) characteristics, contributes to the overall efficiency and reliability of the circuit.

In terms of power handling, the circuit is capable of delivering 5V at a current of 1.5A, with an input voltage range that allows for versatility in various applications. The efficiency ratings at different input voltages indicate the performance characteristics of the design, with considerations for efficiency losses at lower load conditions. Overall, this switch-mode power supply design demonstrates a compact and efficient approach to voltage regulation using widely available components.Most switch-mode power supplies rely on a PWM (pulse-width-modulated) output that is controlled via voltage feedback. A 555-timer IC can inexpensively perform PWM. The circuit in Figure 1 shows how to turn a 555 PWM circuit into an switch-mode power supply with only one simple equation.

The design uses two 555s. IC1, in astable mode, triggers IC2in PWM mode. IC1 is set to oscillate at approximately 60 kHz at a high duty cycle. The output is low for only approximately 2. 5 µsec to trigger the PWM circuit and then goes high for the rest of the period. The PWM circuit has a maximum pulse width of approximately 85 µsec, and it becomes shorter, depending on the control voltage from the feedback circuit. You can reduce the chip count by using a 556 or another continuous-trigger source. The input must be (1. 5VOUT+Margin), so for 5V output you need 9V minimum input. If you use CMOS chips and small timing capacitors C1 and C2, you can keep the operating current low. Thus, you can use a simple zener-diode regulator for the 555 and increase the input voltage to more than 30V.

The input-voltage limit is a function of how much power the zener supply can handle while delivering 5 to 10 mA to the 555s. Q1 has low RDS(ON) and low VGS and can handle more than 40V. D1 clamps any voltage spikes, such as those that occur when a large current flow ceases, causing a large magnetic field to be left in the inductor.

You should select D1 according to the output voltage you need. For 5V output, use a 5. 6V zener diode, for example. IC3, R1, R2, and V1 form the feedback circuit to set the output voltage. The output-voltage equation is VOUT=V1(R1/R2+1). The TL431 is a popular part for setting a voltage reference and can easily create the 1. 25V shown for V1. You can supply 5V at 1. 5A with an input of 9 to 40V. At voltages higher than 12V, you can add a 10V zener-diode supply for the chips. The zener supply only slightly reduces the efficiency. With 12V input, 5V, 1. 5A output efficiency is approximately 70%, and it drops to 65% with a 40V input and a zener circuit. The zener diode`s influence is more noticeable at lower current levels; at a 50-mA load the efficiency drops to approximately 50%. 🔗 External reference

The circuit employs two 555 timer ICs to generate a PWM signal that is essential for the operation of the switch-mode power supply. The first 555 timer (IC1) operates in astable mode, generating a continuous square wave at a frequency of approximately 60 kHz. This frequency is chosen to optimize the switching performance and efficiency of the power supply. The duty cycle is adjusted so that the output remains low for about 2.5 µsec, which serves as the trigger for the second 555 timer (IC2), configured in PWM mode. The PWM output of IC2 is critical for regulating the output voltage of the power supply.

The feedback mechanism is established through the use of a voltage divider formed by resistors R1 and R2, with V1 providing a reference voltage. The output voltage can be calculated using the formula VOUT = V1(R1/R2 + 1), which allows for precise control over the output voltage based on the resistor values. The TL431 voltage reference is a reliable choice for providing the necessary 1.25V reference voltage.

The design also incorporates a zener diode (D1) for voltage spike protection, ensuring the stability of the circuit during transient conditions. The choice of components, including the selection of Q1 with low RDS(ON) characteristics, contributes to the overall efficiency and reliability of the circuit.

In terms of power handling, the circuit is capable of delivering 5V at a current of 1.5A, with an input voltage range that allows for versatility in various applications. The efficiency ratings at different input voltages indicate the performance characteristics of the design, with considerations for efficiency losses at lower load conditions. Overall, this switch-mode power supply design demonstrates a compact and efficient approach to voltage regulation using widely available components.Most switch-mode power supplies rely on a PWM (pulse-width-modulated) output that is controlled via voltage feedback. A 555-timer IC can inexpensively perform PWM. The circuit in Figure 1 shows how to turn a 555 PWM circuit into an switch-mode power supply with only one simple equation.

The design uses two 555s. IC1, in astable mode, triggers IC2in PWM mode. IC1 is set to oscillate at approximately 60 kHz at a high duty cycle. The output is low for only approximately 2. 5 µsec to trigger the PWM circuit and then goes high for the rest of the period. The PWM circuit has a maximum pulse width of approximately 85 µsec, and it becomes shorter, depending on the control voltage from the feedback circuit. You can reduce the chip count by using a 556 or another continuous-trigger source. The input must be (1. 5VOUT+Margin), so for 5V output you need 9V minimum input. If you use CMOS chips and small timing capacitors C1 and C2, you can keep the operating current low. Thus, you can use a simple zener-diode regulator for the 555 and increase the input voltage to more than 30V.

The input-voltage limit is a function of how much power the zener supply can handle while delivering 5 to 10 mA to the 555s. Q1 has low RDS(ON) and low VGS and can handle more than 40V. D1 clamps any voltage spikes, such as those that occur when a large current flow ceases, causing a large magnetic field to be left in the inductor.

You should select D1 according to the output voltage you need. For 5V output, use a 5. 6V zener diode, for example. IC3, R1, R2, and V1 form the feedback circuit to set the output voltage. The output-voltage equation is VOUT=V1(R1/R2+1). The TL431 is a popular part for setting a voltage reference and can easily create the 1. 25V shown for V1. You can supply 5V at 1. 5A with an input of 9 to 40V. At voltages higher than 12V, you can add a 10V zener-diode supply for the chips. The zener supply only slightly reduces the efficiency. With 12V input, 5V, 1. 5A output efficiency is approximately 70%, and it drops to 65% with a 40V input and a zener circuit. The zener diode`s influence is more noticeable at lower current levels; at a 50-mA load the efficiency drops to approximately 50%. 🔗 External reference