8 Channel software controlled fanbus with PWM

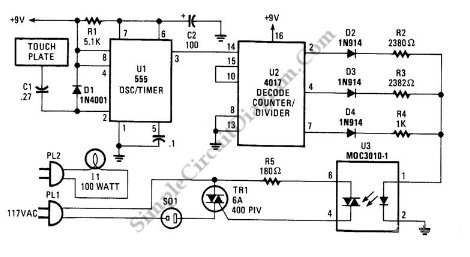

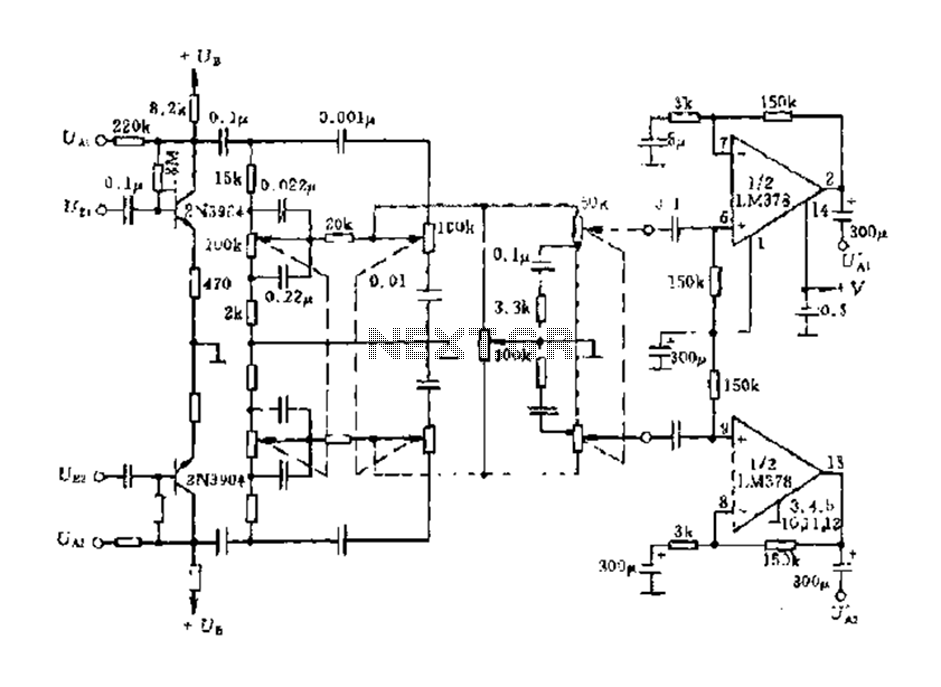

When discussing fan control, there are generally two methods: linear control and pulse-width modulation (PWM) control. Linear control is the most commonly used method, which involves reducing the voltage supplied to the fan. For a fan rated at 12 volts, it is often possible to lower the voltage to around 6-7 volts. However, if the voltage is reduced further, the fan may not start. Another challenge with linear control is achieving stepless regulation, which necessitates a variable resistor (rheostat) or a control circuit utilizing transistors. When running a fan at 7 volts, the remaining voltage must be dissipated as heat in the control circuit or rheostat. Linear control provides a constant voltage to the fan. In contrast, PWM control generates rapid 12-volt pulses, with the timing of the on and off states determining the overall fan speed. Historically, constructing a PWM circuit has been complex, requiring advanced circuits to manage various time constants. However, with CKControl II, all timing signals can be managed via software, allowing the use of a PC parallel port as eight individual, fully controllable PWM outputs. These outputs can be utilized for fans and other devices, such as laser LEDs or cold cathode lights, provided the maximum current output does not exceed 0.8 A per channel. A relay can also be added to control devices like a coffee machine. The number of fans that can be added to the circuit depends on the specific fans used. The electronic components are rated for 1 Ampere per channel, so it is advisable to remain below 0.8 Ampere, or approximately 10 Watts per channel. A standard 80mm fan typically consumes between 0.14 and 0.18 A (1 A = 1000 mA), allowing for about five fans per channel, totaling up to 40 fans across all eight channels. However, this is a theoretical limit, as powering 40 fans would require a robust power supply, as well as thick wires and PCB tracks. Additionally, very few users need to control 40 fans in a desktop computer. It is important to note that this circuit cannot be used to control CPU or GPU coolers. To enhance stability, fans will not begin operation until Windows is loaded and CKControl II is initialized.

A Vero board utilizes horizontal copper tracks that are interconnected, allowing for the construction of smaller circuits. This method is relatively straightforward but requires patience and is best suited for experienced hobbyists. Alternatively, a PCB pen can be used to draw insulating tracks on raw copper plates, followed by etching the exposed copper. While this method is accessible, it demands a steady hand and can yield variable results in terms of aesthetics. Another approach, known as photo printing, offers industry-quality results. This method involves exposing a photosensitive copper plate to UV light, using a transparent paper mask for the layout, followed by developing and etching processes. Although it is more costly, it produces superior quality PCBs. For this project, a PCB has been designed with pre-drilled holes, intended for mounting on the back of a 5.25-inch front bezel. This PCB is available for purchase, providing a convenient solution for those who prefer not to engage in etching or manual drawing. Contact information for purchasing is available on the last page.When speaking of fan control, there are generally 2 ways of doing it, linear control, and pulse-width control. The linear control is the most common. The idea is to decrease the voltage to the fan. If the fan is specified to 12 volts, in most cases you can lower the voltage to 6-7 volts. But if you want to go lower, the result is often that your f ans won`t even start. Another issue is step less regulation. This requires a variable resistor (rheostat) or a control circuit, using transistors. If you want to run a fan at 7 volts, the remaining 5 volts will have to be burned of as heat in the control circuit or rheostat. The linear control supplies the fan with a constant voltage. But the PWM control generates rapid 12 volt pulses, and the on and off timing determines the overall speed of the fans.

Until now, the construction of a PWM circuit has been pretty tricky. It requires an advanced circuit to control the different time constants. But with CKControl II, all timing signals are controlled via the software, allowing us to utilize the PC parallel port as 8 individual, fully controllable PWM outputs. You can use the outputs for not only fans, but all kinds of things including Lazer LED`s, Cold Cathode lights as long as the maximum current output doesn`t exceed 0, 8 A for each channel.

You could even add a relay and make the software turn your coffee machine on and off! How many fans can we add to the circuit, then That depends on the fans used. The electronic components used are specified to 1 Ampere per channel. With that in mind, we should stay below 0, 8 Ampere, or approx. 10 Watt per channel. A standard 80mm fan typically uses 0, 14 0, 18 mA (1 mA = 1/1000 Ampere). That makes 5 fans per channel a total of 40 fans for all 8 channels. But that`s a rather theoretical value; as 40 fans would demand a heavy duty power supply, as well as thick wires and PCB tracks. In addition, considerably few of us uses 40 fans in our desktop computers. You can`t use this circuit to control your CPU or GPU cooler. To increase stability, the fans won`t start running until Windows is loaded and CKControl II is initialised.

1) A so-called Vero board uses horizontal copper tracks, tied together. This makes you able to build smaller constructions, fairly easy, but it takes a certain amount of patience, and is only suitable if you are an experienced hobby-electronics builder. 2) By means of a PCB-pen, it is possible to literally draw insulating tracks on raw copper-plates, and then etch the remaining naked copper away.

It`s an easy way of creating PCB`s, but even with a steady hand, the overall outcome may not look so nice. It also takes some technique and experience to draw a circuit like this by hand. 3) Another method called photo print, gives you industry like quality. It is done by exposing a photosensitive copperplate to UV-light, masking the layout with a transparent paper copy, and then applying developing fluids and finally etching.

It`s quite expensive, but also gives you the finest results. 4) For this project, we have constructed a PCB with the holes already drilled. The PCB is designed to be mounted on the backside of a 5, 25 front bezel. The PCB can be bought from us, and is an easy solution if you`re not into etching and drawing yourself. See the contact info on the last page. 🔗 External reference

A Vero board utilizes horizontal copper tracks that are interconnected, allowing for the construction of smaller circuits. This method is relatively straightforward but requires patience and is best suited for experienced hobbyists. Alternatively, a PCB pen can be used to draw insulating tracks on raw copper plates, followed by etching the exposed copper. While this method is accessible, it demands a steady hand and can yield variable results in terms of aesthetics. Another approach, known as photo printing, offers industry-quality results. This method involves exposing a photosensitive copper plate to UV light, using a transparent paper mask for the layout, followed by developing and etching processes. Although it is more costly, it produces superior quality PCBs. For this project, a PCB has been designed with pre-drilled holes, intended for mounting on the back of a 5.25-inch front bezel. This PCB is available for purchase, providing a convenient solution for those who prefer not to engage in etching or manual drawing. Contact information for purchasing is available on the last page.When speaking of fan control, there are generally 2 ways of doing it, linear control, and pulse-width control. The linear control is the most common. The idea is to decrease the voltage to the fan. If the fan is specified to 12 volts, in most cases you can lower the voltage to 6-7 volts. But if you want to go lower, the result is often that your f ans won`t even start. Another issue is step less regulation. This requires a variable resistor (rheostat) or a control circuit, using transistors. If you want to run a fan at 7 volts, the remaining 5 volts will have to be burned of as heat in the control circuit or rheostat. The linear control supplies the fan with a constant voltage. But the PWM control generates rapid 12 volt pulses, and the on and off timing determines the overall speed of the fans.

Until now, the construction of a PWM circuit has been pretty tricky. It requires an advanced circuit to control the different time constants. But with CKControl II, all timing signals are controlled via the software, allowing us to utilize the PC parallel port as 8 individual, fully controllable PWM outputs. You can use the outputs for not only fans, but all kinds of things including Lazer LED`s, Cold Cathode lights as long as the maximum current output doesn`t exceed 0, 8 A for each channel.

You could even add a relay and make the software turn your coffee machine on and off! How many fans can we add to the circuit, then That depends on the fans used. The electronic components used are specified to 1 Ampere per channel. With that in mind, we should stay below 0, 8 Ampere, or approx. 10 Watt per channel. A standard 80mm fan typically uses 0, 14 0, 18 mA (1 mA = 1/1000 Ampere). That makes 5 fans per channel a total of 40 fans for all 8 channels. But that`s a rather theoretical value; as 40 fans would demand a heavy duty power supply, as well as thick wires and PCB tracks. In addition, considerably few of us uses 40 fans in our desktop computers. You can`t use this circuit to control your CPU or GPU cooler. To increase stability, the fans won`t start running until Windows is loaded and CKControl II is initialised.

1) A so-called Vero board uses horizontal copper tracks, tied together. This makes you able to build smaller constructions, fairly easy, but it takes a certain amount of patience, and is only suitable if you are an experienced hobby-electronics builder. 2) By means of a PCB-pen, it is possible to literally draw insulating tracks on raw copper-plates, and then etch the remaining naked copper away.

It`s an easy way of creating PCB`s, but even with a steady hand, the overall outcome may not look so nice. It also takes some technique and experience to draw a circuit like this by hand. 3) Another method called photo print, gives you industry like quality. It is done by exposing a photosensitive copperplate to UV-light, masking the layout with a transparent paper copy, and then applying developing fluids and finally etching.

It`s quite expensive, but also gives you the finest results. 4) For this project, we have constructed a PCB with the holes already drilled. The PCB is designed to be mounted on the backside of a 5, 25 front bezel. The PCB can be bought from us, and is an easy solution if you`re not into etching and drawing yourself. See the contact info on the last page. 🔗 External reference