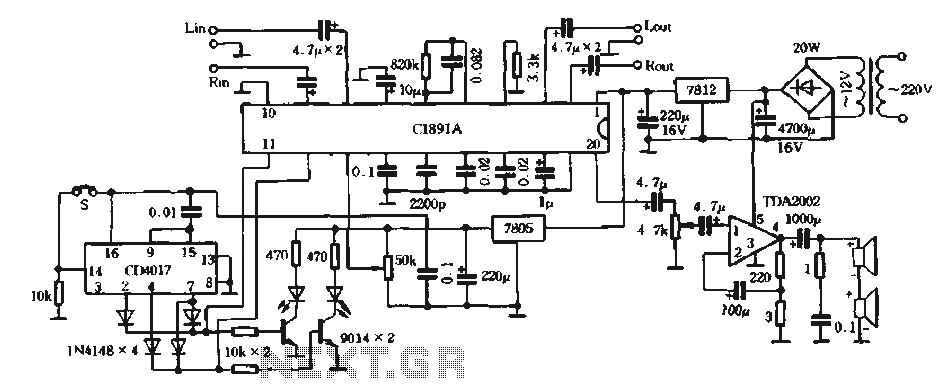

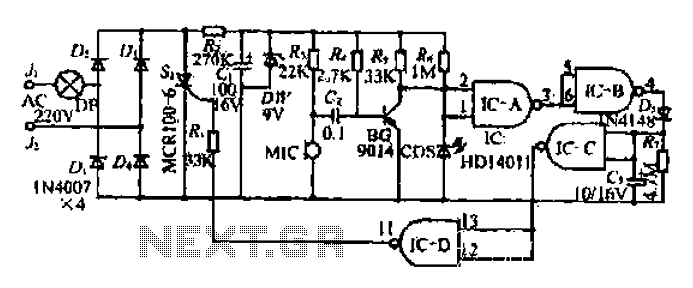

A sound and light control energy-saving switch circuit

The circuit operates at 380V for air flow. Power is supplied through a step-down transformer, which rectifies the output to 9V DC. When the pump operates correctly, a button labeled 'S' is activated. The circuit utilizes a TWH8778 component. The unset condition is triggered by a photoelectric coupling device that serves as a bidirectional trigger for signal detection. A silicon triac conducts via variable flood contactor operation. When the contact closes, it connects to an electromechanical device that activates the water pump. After the pump expels water, the A and B ends are shorted. The TWH8778 insurance protection activates, allowing the system to continue functioning. If the pump operates continuously for ten hours and the water is drained, the A and B connections become disconnected. The F switch circuit in the TWH8778 is then activated, cutting off the triac conduction and releasing the contactor, thereby stopping the pump motor. During installation, two electrical connections labeled A and B can be positioned at the pump outlet. An optical coupling device is employed for safety to prevent electric shock incidents through a resistance resistor.

The circuit design incorporates a step-down transformer to convert the high voltage (380V) to a lower voltage (9V DC), suitable for driving the control logic and associated components. The TWH8778 component plays a crucial role in ensuring safety and operational integrity by providing insurance protection against electrical faults. The photoelectric coupling device serves as an essential interface for detecting conditions that require the pump to operate or shut down, ensuring that the system responds accurately to environmental changes.

The use of a silicon triac allows for efficient control of the pump motor through the variable flood contactor, which is responsible for managing the power to the pump based on the signals received. The operational logic ensures that when the pump is active, the A and B connections are shorted, allowing for continuous operation. However, once the water level drops significantly, the system automatically disconnects these connections, triggering the F switch circuit in the TWH8778. This action cuts off the triac conduction, thereby stopping the pump motor to prevent damage due to dry running.

Safety features are built into the design, including the optical coupling device, which isolates the control circuit from the high voltage, minimizing the risk of electric shock. The resistance resistor further enhances safety by limiting current flow in case of a fault condition. This comprehensive approach ensures that the system is not only effective in its primary function of pumping water but also prioritizes user safety and equipment longevity.380V air flow I. Power through step-down transformer, rectifier output 9V DC oxime arrested. When the pump working fine basket lr. uT shake F 41Sf button S. * Circuit TWH8778 s unset is triggered - ~ .iHi, photoelectric coupling device to the bidirectional trigger IJr care mound i catch lll signal, bite Zhu silicon 3C: T i via conduction, variable flood contactor work. Its contact closed sets, connected to electric electromechanical {busy, pumping out water pumps. After pumping the pump nozzle from the water A. B ends shorted. TWH8778 insurance protection is turned on, then release the S. Pump still working properly. If the child after ten hours of continuous pumping after the ball well towel water is drained, A, B intoxicated end Anhydrous disconnected,} F switch circuit TWIf8778 is set.

And cut, triac also j ; conduction, contactor K release, pump motor will stop working. When installing, A, B two electric rice can be installed in place pump landscape mouth. Indiscriminately using optical coupling device in abundance to L security point of view, to prevent resistance resistor R. take a small electric shock accident.

The circuit design incorporates a step-down transformer to convert the high voltage (380V) to a lower voltage (9V DC), suitable for driving the control logic and associated components. The TWH8778 component plays a crucial role in ensuring safety and operational integrity by providing insurance protection against electrical faults. The photoelectric coupling device serves as an essential interface for detecting conditions that require the pump to operate or shut down, ensuring that the system responds accurately to environmental changes.

The use of a silicon triac allows for efficient control of the pump motor through the variable flood contactor, which is responsible for managing the power to the pump based on the signals received. The operational logic ensures that when the pump is active, the A and B connections are shorted, allowing for continuous operation. However, once the water level drops significantly, the system automatically disconnects these connections, triggering the F switch circuit in the TWH8778. This action cuts off the triac conduction, thereby stopping the pump motor to prevent damage due to dry running.

Safety features are built into the design, including the optical coupling device, which isolates the control circuit from the high voltage, minimizing the risk of electric shock. The resistance resistor further enhances safety by limiting current flow in case of a fault condition. This comprehensive approach ensures that the system is not only effective in its primary function of pumping water but also prioritizes user safety and equipment longevity.380V air flow I. Power through step-down transformer, rectifier output 9V DC oxime arrested. When the pump working fine basket lr. uT shake F 41Sf button S. * Circuit TWH8778 s unset is triggered - ~ .iHi, photoelectric coupling device to the bidirectional trigger IJr care mound i catch lll signal, bite Zhu silicon 3C: T i via conduction, variable flood contactor work. Its contact closed sets, connected to electric electromechanical {busy, pumping out water pumps. After pumping the pump nozzle from the water A. B ends shorted. TWH8778 insurance protection is turned on, then release the S. Pump still working properly. If the child after ten hours of continuous pumping after the ball well towel water is drained, A, B intoxicated end Anhydrous disconnected,} F switch circuit TWIf8778 is set.

And cut, triac also j ; conduction, contactor K release, pump motor will stop working. When installing, A, B two electric rice can be installed in place pump landscape mouth. Indiscriminately using optical coupling device in abundance to L security point of view, to prevent resistance resistor R. take a small electric shock accident.