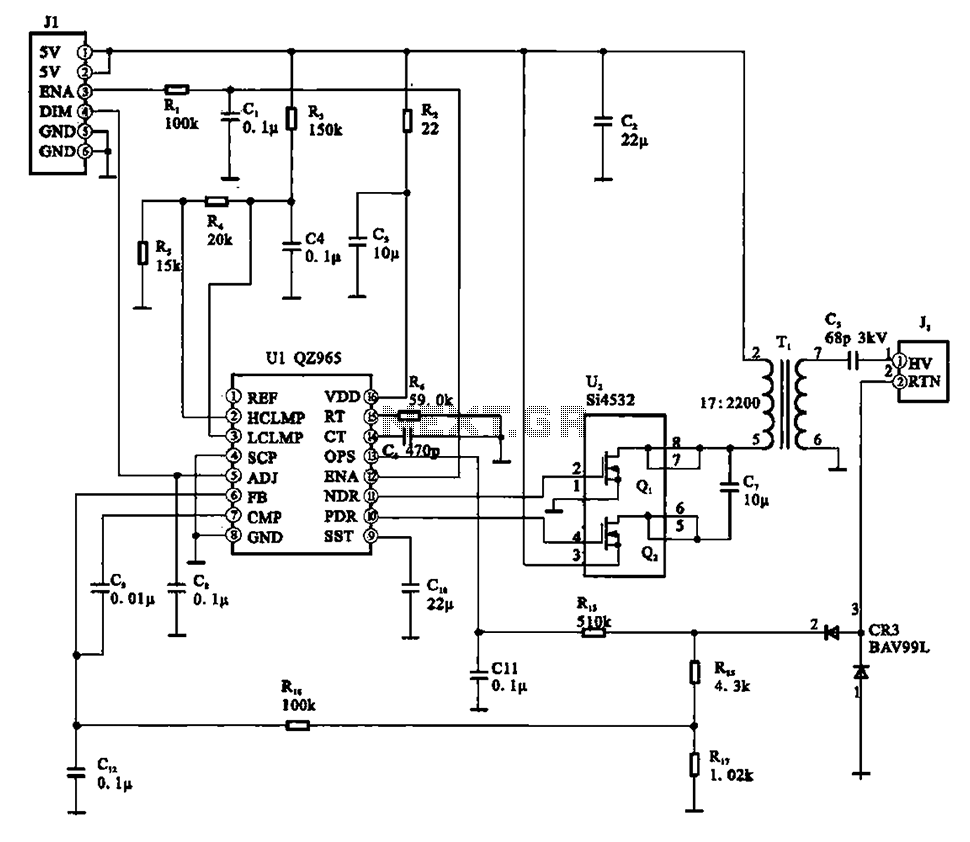

A typical liquid crystal display inverter circuit OZ965

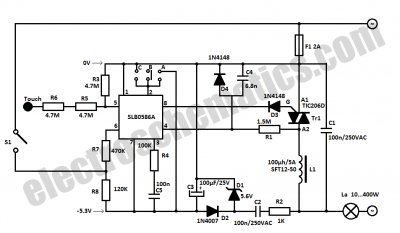

A typical liquid crystal display inverter circuit (OZ965) is primarily controlled by the OZ965 chip. It includes a driving field effect transistor (U2), a step-up transformer, the backlight socket, and associated circuitry. A 5V DC voltage is provided by the control chip at pin J1. This voltage is filtered by capacitor C2, which drives a field effect transistor (U1) connected to the step-up transformer for power supply. An enable control signal (ENA) is input through pin J1 into the control chip. Once the inverter circuit is activated, the output from pin U1 generates two opposite phase PWM pulse signals, which drive the field effect transistor (U1) and increase the voltage from the step-up transformer to approximately 800V, powering the backlight lamp through the backlight socket.

The liquid crystal display inverter circuit utilizing the OZ965 chip is designed to efficiently convert low voltage DC into high voltage AC, suitable for powering the backlight of LCD panels. The circuit begins with a 5V DC input supplied to the OZ965 control chip via pin J1, which is responsible for regulating the operation of the entire circuit.

Capacitor C2 plays a crucial role in filtering the input voltage to ensure a stable supply to the field effect transistor (U1). This transistor acts as a switch that modulates the current flowing into the step-up transformer. The transformer is essential for elevating the voltage from the low 5V level to the required high voltage, which is necessary for the operation of the backlight lamps.

The enable control signal (ENA) is sent to the OZ965 chip, indicating that the inverter circuit should begin operation. Upon activation, the chip generates two PWM signals at the output pin U1, which are 180 degrees out of phase. These signals drive the field effect transistor (U1) in a manner that allows for efficient energy transfer to the step-up transformer.

As a result of this operation, the transformer steps up the voltage significantly, reaching approximately 800V. This high voltage is then delivered to the backlight lamp socket, effectively illuminating the LCD panel. The design of this inverter circuit exemplifies a compact and efficient solution for powering LCD backlights, utilizing a combination of modern semiconductor technology and traditional transformer principles. The overall configuration ensures reliable performance and longevity of the backlight system in various display applications.A typical liquid crystal display inverter circuit (OZ965) It shows a typical liquid crystal display of the inverter circuit, which is mainly controlled by the 02965 chip, the d riving field effect transistor U2, step-up transformer, the backlight socket part and associated circuitry configured. After 5v DC voltage by the control chip UI widget Jl provided (02 965) of the pin DC voltage; at the same time, by filtering electrical pit C2 after driving to a field effect transistor Ul step-up transformer and power supply; enable control signal (ENA) through plug Jl feet into the control chip, after the inverter circuit starts from the Ul feet pin output two opposite phase PWM pulse signal, the drive field effect transistor Ul put into large after the step-up transformer, the rise the pulse voltage transformer voltage up to about 800V, by backlight backlight lamp socket to power.

The liquid crystal display inverter circuit utilizing the OZ965 chip is designed to efficiently convert low voltage DC into high voltage AC, suitable for powering the backlight of LCD panels. The circuit begins with a 5V DC input supplied to the OZ965 control chip via pin J1, which is responsible for regulating the operation of the entire circuit.

Capacitor C2 plays a crucial role in filtering the input voltage to ensure a stable supply to the field effect transistor (U1). This transistor acts as a switch that modulates the current flowing into the step-up transformer. The transformer is essential for elevating the voltage from the low 5V level to the required high voltage, which is necessary for the operation of the backlight lamps.

The enable control signal (ENA) is sent to the OZ965 chip, indicating that the inverter circuit should begin operation. Upon activation, the chip generates two PWM signals at the output pin U1, which are 180 degrees out of phase. These signals drive the field effect transistor (U1) in a manner that allows for efficient energy transfer to the step-up transformer.

As a result of this operation, the transformer steps up the voltage significantly, reaching approximately 800V. This high voltage is then delivered to the backlight lamp socket, effectively illuminating the LCD panel. The design of this inverter circuit exemplifies a compact and efficient solution for powering LCD backlights, utilizing a combination of modern semiconductor technology and traditional transformer principles. The overall configuration ensures reliable performance and longevity of the backlight system in various display applications.A typical liquid crystal display inverter circuit (OZ965) It shows a typical liquid crystal display of the inverter circuit, which is mainly controlled by the 02965 chip, the d riving field effect transistor U2, step-up transformer, the backlight socket part and associated circuitry configured. After 5v DC voltage by the control chip UI widget Jl provided (02 965) of the pin DC voltage; at the same time, by filtering electrical pit C2 after driving to a field effect transistor Ul step-up transformer and power supply; enable control signal (ENA) through plug Jl feet into the control chip, after the inverter circuit starts from the Ul feet pin output two opposite phase PWM pulse signal, the drive field effect transistor Ul put into large after the step-up transformer, the rise the pulse voltage transformer voltage up to about 800V, by backlight backlight lamp socket to power.